Written by James Warne from Soil First Farming

A word of warning to all of you who buy bulk lime products. There appears to be nobody in the supply chain fighting your corner to ensure the quality of the lime you buy meets the legal requirements as laid down in the Fertiliser Regulations 1991. 100% of the bulk lime products we see tipped on farm does not meet these specifications in terms of particle size. Even if it’s being sold as screened lime it fails to make the specification. This low quality lime will not be able to neutralise soil acidity as quickly, or for as long, resulting in declining crop performance. I encourage everyone buying bulk lime products to take a sample from the delivered pile before spreading and get it tested for Neutralising Value (NV) and particle size distribution to make sure it meets to specifications of the product. The correct specification is given in the table below. If the analysis results show substandard product, talk to your supplier and send the results to the Aglime Association. It’s only by collective effort that we can encourage change. Always request ground agricultural lime from your supplier and put it in writing.

The Aglime Association, which represents lime producers, has launched its own assurance standard to ensure product consistency from the quarries. But why do we need another assurance standard when the supply requirements are laid down in law? I mention this topic regularly for good reason. Farmers are paying for sub-standard inputs which can be very costly, not only in the purchase and spreading price, but also the knockon effects of reduced output. Low soil pH can negatively affect nitrogen use efficiency. With urea trading at ~£700/per tonne you need to ensure that you are maximizing its efficiency.

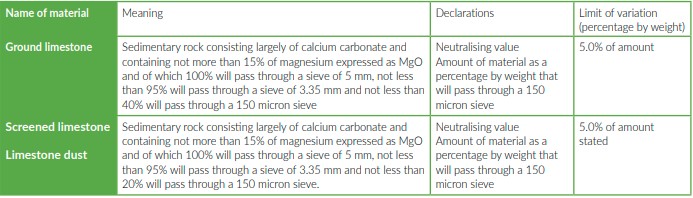

All ag-lime sold in the UK must meet the requirements of the Fertiliser Regulations 1991 to be sold as lime, for the purposes of this article I will look at limestone only, but these regulations also apply to dolomitic limestone, chalk and many other types of lime. The table below is taken from the Fertiliser Regulations.

Grind size

Don’t just buy on neutralising value, the particle size distribution is critical, almost more so. To put it in context, Lincoln Cathedral has a neutralising value, it’s built of limestone after all, but it won’t neutralise very mush due to the low surface area to volume ratio. Grind the stone to 150 micron and it will neutralise acid, provide plant available calcium and react well. Once the levels start to decline the effectiveness of inputs also starts to decline and the return on investment declines alongside. The health of the crop suffers which results in an increase in inputs which are already under pressure. You can see this becomes an ever-decreasing circle of increased cost and decreasing output.

As mentioned above we now know that grind size is as important as neutralising value in determining whether the lime will actually do as intended. This is where the fertiliser Regulations 1991 become relevant because they set out the standards for lime quality as a fertiliser. If we consider these regulations for a moment it is clear that both the neutralising value and the specific material name must be given, in addition the percentage by weight passing through a 150 micron sieve must also be declared (the grind size). A limit of variation (tolerence) of 5% is allowed.

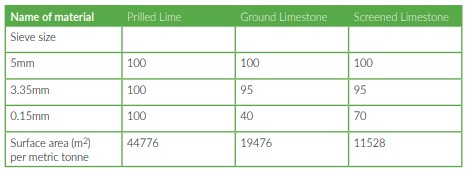

By grinding the rock finer we are increasing the surface area of the product. It is this increase in surface area which allows the lime to react faster and bring about quick reductions in soil acidity. If we calculate the degree of grinding and surface area we can see from the table above that ground limestone has a surface area nearly twice that of screened limestone, while prilled lime products can be four times the surface area of screened limstone. This increase will give greater reaction and therefore faster pH reduction.

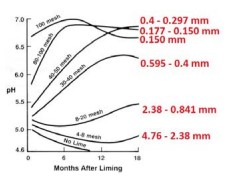

So how fine does the rock need to be ground to be effective? The aglime website states that “coarser material requires a heavier application” and “There is a considerable reduction in the effectiveness of liming materials containing particles above 600 microns (0.60mm, 60 mesh) unless the material is easily broken down”. The finer the lime is ground, the more effective it becomes. This is supported by work taken from North Carolina University in the US shown to the right;

This graph clearly demonstrates that lime in the range of 0.177 – 0.150mm (177-150 micron or 80-100 mesh) gave the quickest pH rise and most sustained pH rise. The larger particle size 0.841mm and above gave a very limited pH increase and took 18 months to achieve it. Focus on the detail of the basics and the output and profitability will follow. My advice to you is avoid buying bulk lime altogether because you cannot guarantee what you are going to receive and instead buy a guaranteed quality product such as a prilled lime which will work for you every time.