If you would like a printed copy of any of our back issues, then they can be purchased on Farm Marketplace. You can also download the PDFs or read online from links below.

-

How To Start Drilling For £8K

Clive Bailye’s seed drill of choice is his 6m John Deere 750A , which has been used exclusively for 3-4 seasons. Last year, with an increased acreage, the founder and publisher of this Direct Driller magazine thought a second seed drill was necessary. Having just the one machine was a risk and in a difficult season would mean drilling was delayed. He looked around and found a good condition Horsch CO6 tine drill advertised in Germany.

Words and pictures by Mike Donovan

After delivery he rebuilt the coulters to a narrow profile so as to reduce soil disturbance. He says the tine drill is very useful driling after straw crops such as osr and also through the straw on second crop cereals.

Buying the drill from a German farmer was not particularly complicated, and provided him with a higher spec machine than Horsh sell in the UK. The seed dart tyres are much wider, and the machine is fitted with blockage monitors as well as full width front packers and also a liquid fert application system.

A sheaf of photos were taken, and Clive then asked for some of specific parts to show wear. The deal was done at under £5,000 which Clive says is the market value of these machines which are too large for small farmers to buy. Original owners like to buy new and sell when the machine is still in good condition.

Narrow tines with wear tiles

@Clive knew he wanted to make changes, substituting the Horsch tines and coulters for something far narrower, and has ended up getting his own design of tine made, which has a wear tile made from Ferobide, far harder than tungsten. The drill is on the farm primarily for osr and 2nd crop cereals drilled into chopped straw and the 25cm spacing is okay for these crops.

Comments on Clive’s on-line forum, TFF, said the drill many not be so good with beans, as the slot is a mere 12mm wide. And in barley the spacing may well be too wide as it needs to be thick. Clive points out that the seed pipe can actually be a bit wider than 12mm as it is in the shadow of the point. It would be good to have the option of using it for beans.

Above left: The cheap CO6 is being calibrated ready for its first outing

Above right: The adapted Horsch is being filled by the home built drill logistics trailer with seed and liquid starter fert.

Getting around the German instructions

The Horsch came, of course, with a control box and instructions in German. More on-line discussion revealed that English instructions were available on the Horsch website, and another explained that Horsch was sourcing some of these parts from Agton in Canada anyway. Zealman from New Zealand explained that the button marked with callipers should be held down for around 5 seconds. The menu is where you adjust the tramline sequence, valve layout and row numbers.

Ball hitch is a continental standard and provides a positive connection between tractor and drill

The Stocks Wizard has a rotor modified for Avadex which otherwise leaks everywhere

A Stocks Wizard is on the back of the drill and used for Avadex. Here again the knowledge of actual farmers is helpful. Alistair Nelson warned that the rotor and the surrounding shroud need to be changed, and he got good advice “from Rick at Stocks”. Clive has the same setup on the 750A and says that the Avadex leaks everywhere unless the modification is made. The drill was acquired and modified in 2016 and the results have been excellent.

The machine went through the residue without many problems and having the second drill has meant more timely planting. Clive has shown that moving into No-Till is not the expensive exercise so many farmers think it might be. The total cost, after modifications which included replacing all tines and coulters, was under £8,000.

Author Mike Donovan writes: we have featured a number of home made direct drills in @Practical Farm Ideas, and are always interested in seeing more. Please contact mike editor@farmideas.co.uk or 07778877514.

-

John Deere – Farm Smart, Profit More

All you need to know in one ad… See John Deere in the drill arena for Direct Driller at Cereals on 11 & 12 June, Bygrave Woods, Newnham Farm, Herts

-

Covering Soils Event – Scotland – 22nd May 24

A first event in Scotland, at Direct Driller’s Farmer Focus writer Neil White’s farm in Berwickshire

Date and time

Wed, 22 May 2024 10:00 – 16:00 BST

Location

Greenknowe Farm Cottages, Duns, TD11 3JA

Description

Gain insights to make the best decision for your farm – Everything starts with soil, it’s the foundation and biggest asset on farm, measure what you have and make informed, practical decisions based on the data. Focus will be on sustainability, holistic practices and practical optimization of land use.

The day is based on Neil’s farm in Berwickshire – encourage.theory.events (what3words)

If you haven’t read Niel’s artilces, they are all on the Direct Driller website here: https://directdriller.com/author/neil-white/

Follow Neil for daily updates on his socials:

X – @GreenknoweFarm

YouTube – @everythingisgreenknowe5094

Instagram – everything_is_greenknowe

What you can learn on the day

During the day you will get the chance to speak to Neil and see his farm.

Neil uses a Mzuri Drill and a Valtra tractor and teams from both will taking a session during the day to explain why they suit the conditions Neil farms in perfectly and the new techology they have coming the market.

During the day you will also hear from Stuart Fensom, SOYL and Ed Jones, Kings talking all things cover crops, soil health and analysis. Thorburn Group who are the main agents for AGREX Grain Dryer’s will also be there. In addition to the demonstration, you will have the opportunity to speak to the team about the best grain stores they have erected over the years, and gain their advice on what the benefits of a farm building investment are.

Sponsors

- Frontier (Kings Cover Crops and SOYL)

- Mzuri Ltd

- Valtra part of the Agco Group

- Thorburn Group who re the main agents for AGREX Grain Dryers

The day will run a morning and afternoon session, groups will swap over with lunch in between to keep the sessions small and personal.

A word from Neil’s last Farmer Focus piece:

“I’m not going to dwell on the weather but as it is a major factor in what we do, I will say, despite having constant downpours of around 40-50mm we have fared better than most. My rain gauge filled so many times I must admit I gave up emptying it. Colin McGregor, 4 miles away, didn’t give up, and tells me that we had 45% of our annual rainfall in the last 3 months of 2023. We both agreed that once again we have been very fortunate in this area compared to large parts of the country both North and South.

The SFI scheme has maybe become more appealing in a year with so many challenges, and stories about 27% of ground already being taken out of production is a big concern. I don’t blame anyone for making that judgment based on the prospects short term. We don’t have that scheme north of the border so its more of the same for us, which means very little opportunity to enter any scheme for me.”

Register here: https://www.eventbrite.co.uk/e/covering-soils-scotland-hosted-by-neil-white-tickets-888349095057

-

The Aitchison T- Boot

Article written by Aitchison. See Aitchison at Direct Driller at Cereals 11 & 12 June, Bygrave Woods, Newnham Farm, Herts.

The vibrating tine with the Aitchison boot creates a smear-free, cocoon-shaped mini seedbed. Competing plants have their roots pruned while the inverted T-slot mixes the seeds with the soil. The seeds may be placed 1.5″ deep in the inverted T-slot where more moisture is available; however, the seed is consistently covered with only 1/4″ to 3/8″ of finely tilled soil. The key that makes the Aitchison completely different is the special design of the Aitchison boot. The bottom surface of the boot compresses a column of soil underneath the seed, which creates a “wick” to conduct moisture upwards. The unique inverted T-shaped slot retains up to eight times more moisture and three times more oxygen than other planting systems, while offering superior seed germination. The loose, tilth-like soil deposited over the seed with the Aitchison system is a poor water conductor and acts as a barrier to stop moisture from evaporating from the seedbed. Seed savings can be 25% or greater over other drills due to improved emergence. This fact is supported by independent trial results.

About Aitchison

The Aitchison Zero Till Drills sowing the future of agriculture. The drill’s seeding technique uses the famous and original T-boot system, coupled with the unique gentle sponge seed delivery system is able to dispense any size seed in any seed mix. Drills are available in sowing widths 1.2m-6m, tine or disc.

Contact Neil Ford – Mobile 07487301846

-

Editor of Direct Driller Magazine caught on camera!

Article written by the the team at Direct Driller Magazine

As you already know, we love to showcase those who deserve the limelight and the editor of our magazine is no exception!

We visited the Cereals Event for their cover crop plot day back in April and had an impromptu moment in front of the camera, which, when you’re an editor of a mag, isn’t usually the place you find yourself but we think he did fantastic!

Check out the video below of Chris giving you all you need to know about Direct Driller Magazine at Cereals in June, we think he needs to spend more time in front of the screen instead of behind it! Well done Chris and see you all at the arable event in June. Tickets available to buy, here: https://directdriller.com/direct-driller-cereals/

Chris Fellows on camera giving you information about Direct Driller Magazine at Cereals 2024

-

Giving your crops what they want – where and when they want it

Article written by Claydon Drills. See Claydon Drills for Direct Driller at Cereals on 11 & 12 June 2024, Bygrave Woods, Newnham Farm, Herts

Food in the best format

Claydon drills have the facility to apply granular fertiliser through a variety of different outlets and locations. With the improved soil health and uncultivated rows from the Claydon Opti-Till® system the infiltration capacity is greatly improved, facilitating more timely applications of fertilisers, or chemicals, as the soil structure is more supportive for machines throughout the year.

The Claydon drill is a direct drill, seeding into crop residues which have been dispersed and broken down into a mulch by the Claydon Straw harrow. After a few weeks this organic matter is hardly visible; it has been further broken down and ingested by soil biota, such as earthworms who excrete it as soil nutrients.

This organic matter improves the structure of the soil and increases its ability to hold water, vital to supply crops in the growing months. It helps soil store essential nutrients and promotes root growth, increasing the plant’s uptake of nutrients and water.

The amount of organic matter on the Claydon farm has increased by 5% since 2002.

Prof Andy Neal at Rothamsted Research states that for a silty-clay loam ‘every 1% increase in soil organic carbon equates to a water holding capacity increase of 354,000 litres a hectare to a depth of 30cm’ – which equates to roughly 1.7m litres/ha more water held on the Claydon farm.

Increasing organic matter and improving soil structure has made it possible to grow oilseed rape in Central Spain where retaining moistures is essential on extremely dry land which is light and erodes if cultivated. The farmer has been Claydon drilling for 10 years. The oilseed rape was seeded on 13 September and has had 50m3 of liquid manure and 30kg of N since drilling.

Growing this oilseed rape in central Spain has been made possible with organic matter increase achieved by Claydon Opti-Till® Food where needed

The Claydon drill range offers a variety of options for fertiliser placement when seeding, so fertiliser can be placed where young plants need it for optimum establishment.

The Hybrid T range of trailed drills has split hoppers with fertiliser delivery either above the seed in the seeding zone or below the seed in the rooting zone. Split hoppers are also available on the Evolution 3m and 4m mounted drills with the same options for placement.

An additional fertiliser hopper is available on the trailed drills (NutriSeeder) and mounted drills (Microgranular) with delivery at three outlets: venturi, spread across the rear toolbar or inter-row.

Emerging from a long cold winter in Norway, this winter wheat was established in south eastern Norway where temperatures range from -20°C to +25°C. Placing fertiliser whilst drilling is almost a necessity in this part of the world and this crop has come through well.

Protecting the crops at the optimum time

Claydon drilling only loosens soil in the seeding and rooting zone, leaving the inter-row undisturbed. The structure of the soil, with all the worm channels, capillary action and biota, is left intact and in good shape. This keeps wheeling and compaction to a minimum as the soil is strong enough to support following traffic. Field operations like spraying can be carried out at optimum times when the crop needs; you can travel when you need to travel.

Claydon drilling leaves the soil supportive for optimum timing of following operations. In the next edition of Direct Driller at Cereals – two new product launches which complement the Claydon fertiliser offering.

For more information about how Claydon drilling can help you establish your crops in a challenging climate, whilst maintaining yields and reducing costs, please visit claydondrill.com or contact your nearest Claydon dealer.

https://claydondrill.com/ -

Dale Drills: Update on the Farm Equipment & Technology Fund 2024 (FETF)

Article written by Dale Drills . Come and see Dale Drills the 11 & 12 June for Direct Driller at Cereals, Bygrave Woods, Newnham Farm, Herts.

With the approaching deadline of the first round of applications for the Farming Equipment & Technology Fund (FETF) on April 17, 2024, Dale Drills is delighted by the strong interest shown in our seed drill range. While we have received numerous phone calls and enquiries, we are still encouraging further interest. To assist farmers in determining which drills in our range are eligible for specific codes, we have outlined them as follows:

- FETF205: Direct Drill 4m and above. Eligible for 50% of the drill’s value up to a maximum grant of £17,845.

- FETF206: Direct Drill 3m and above with fertiliser placement. Eligible for 60% of the drill’s value up to a maximum grant of £40,800.

- FETF44: Direct Drill 3m and above. Eligible for 50% of the drill’s value up to a maximum grant of £15,076.50.

- FETF45: Direct Drill 6m and above. Eligible for 50% of the drill’s value up to a maximum grant of £27,900.

We anticipate two more rounds of funding applications after the first round closes. We will provide an update once the opening and closing dates for these rounds are announced.

Dale Drills is committed to assisting farmers in optimising their operations with innovative equipment, and the FETF offers a valuable opportunity for those interested in integrating our seed drills into their farming practices. Don’t miss the chance to enhance your productivity and contribute to a more sustainable agricultural landscape. Contact us today to explore how Dale Drills can be a strategic partner on your journey toward efficient and environmentally conscious farming practices.

-

INTRODUCING THE GH400 MODULAR GRANULAR HOPPER

Article written by Horizon Agriculture . See Horizon at Direct Driller at Cereals on the 11 & 12 June 2024, Bygrave Woods, Herts

Horizon Agricultural Machinery is excited to announce our new small granular hopper, the GH400!

Extremely configurable and versatile, the GH400 is designed to work with various machines and products and features our high-performance DSX metering unit.

Designed to be as modular as possible, the GH400 can easily be combined with Horizon machines or as a standalone platform for machines from other manufacturers. It can be controlled through RDS Artemis ISOCAN Monitor or ISOBUS and features touch button calibration.

All our GH400 models have a 400L pressurised hopper and DSX metering unit with interchangeable rollers, ideal for metering micro-granular fertiliser, slug pellets, Avadex or small seeds. It can be configured in the following different specs:

- The GH400-A: Our ‘airflow’ spec acts as a third or fourth hopper for our DSX platform and upcoming 9m DSX, utilising the existing turbine and distribution system.

- The GH400-O: Our ‘outlet’ configuration features a turbine and distribution system with integrated outlets to create a completely independent seeding unit. This option is designed for machines with 4-12 outlets, and the distribution system with integrated outlets keeps the hopper extremely compact. Compatible with our PPX and SPX.

- The GH400-D: Our ‘distribution’ specification includes a turbine, injector box assembly for selective seeding and distribution heads as it is designed for machines with 6-64 outlets. This configuration can also serve as a standalone seeding unit, and is perfect for combining with a mounted drill. Compatible with our DSX and MDSX.

The tried and tested DSX metering unit found in all our GH400 models has proved extremely accurate, and the interchangeable rollers accommodate a variety of products, working widths and speeds, with 0.5kg per/ha now achievable.

The GH400’s modularity makes it a great choice for pairing with third party machinery and is eligible for 2024’s FETF207 grant when paired with a drill of at least 3m working width.

Contact us, your local Horizon dealer, or visit the GH400 webpage to find out more and learn what it can do for you.

-

Issue 27 – Contents

Inside this issue:

- Introduction – Issue 27 – Following the money

- To be or not to be

- Farmer Focus – Ben Taylor-Davies

- Is regen farming producing more nutritious food?

- Long awaited clarity for carbon accounting tools

- Farmer Focus – Tim Parton

- A sky-high revolution in crop research.

- Farmer Focus – Anna Jackson

- BYDV-Resistant Wheat

- The Challenge of Wet, Compacted Soils

- Tech defines how inputs are applied

- Achieving the potato impossible

- Farmer Focus – Phil Rowbottom

- Crop nutrition after the storm…

- Drill Manufacturer in Focus – Jeff Claydon

- Farmer Focus – John Farrington

- BASE-UK – Conference 2024 – Learning from Experience!

- Revolutionising Farm Purchases: How Farmdeals is Changing the Game for UK Farmers

- Sustainable Dairy: The Key Role of Soil Carbon

- Farmer Focus – Billy Lewis

- Farming’s fungi focus: Considering belowground to benefit above ground

- Farmer Focus – Neil White

- Agriculture has landed at an interesting turning point – where do we go now?

- Navigating the Storm: Challenges in agriculture

- Drill Manufacturer – Dale Drills

- DD Conference Area within Cereals

- Agronomist in Focus – Mike Thornton

- Farmer Focus – Andy Cato

- Changing crops in a changing climate

- Drill Manufacturers – Mzuri

- Moore Unidrill Celebrates 50 Years of Innovation with the All-New Grain & Fert Hopper Unidrill

- Nitrogen release from cover crops

- Getting to the Roots of Black-Grass’s Waterlogging Tolerance

- Cover crops for integrated weed management

- Bayer and Trinity Agtech join forces to drive regenerative practices in agriculture

-

Introduction – Issue 27 – Following the money

It looks like arable movers, shakers and advisors seem to be moving away from yield, costs and profits towards the birds, bees and ecology. They’re ‘following the money’ as Warren Buffett might say. Today they are making the choice between AHL1 (pollen and nectar flower mix) at £739 / ha/year or leaving their Sustainable Farming Incentive programme at AHL3, (grassy field corners and blocks) at £590. The question is “will the marginal returns of going for the more expensive mix cover the added expense over the field corners?

Are the corners going to satisfy outcomes more easily than the pollen?” The SFI actions can extend to 25% of the farm, enough to alter investment decisions “will we need that bigger seed drill, combine or tractor when our acreage is reduced?” “Should we max out on SFI on the basis that the world grain market will continue to be well supplied with static or even depressed prices, even in a world with wars, storms, flood and drought?”

Advisors will be following the money as well. Graduates in ecology or environmental science find multiple openings for salaried work with numerous organisations which, only a few years ago, had no-one looking after this side of their business. It’s a new science with tentacles that reach back to the development of life on earth. It was not so long ago that ecology and the environment were areas of study that had a dilettante appeal that competed with art history and other esoteric areas of study. Ecology today has become mainstream and headline news, and there’s a danger it will leave the study and world of agriculture in it’s wake. Why not have both?

The agronomist who can advise on outcomes of both crop production and ecological enhancement has two vital feathers to their bow. The advisor who understands the downsides and well as benefits of traditional chemistry but who also has knowledge and experience in using bio-stimulants of all varieties is likewise one who can make the most of both nature and the continuously changing technology of agri-chems in its widest sense. Research and progress needs to continue at a useful pace, keeping on top of challenges which will present themselves as a consequence of climate change and other events.

What starts off as being a basic study leads to dozens of important interlinked pathways, all having a major significance to food production and other farming outcomes. I truly believe that Direct Driller has a lead in publishing the integration of farming and ecology in the quality of it’s articles (thank you contributors), and the quality of its readers (thank you, readers). I am always interested in contacts with both groups. mike@ farmideas.co.uk

-

To be or not to be

Never fear, I’m not venturing into Shakespeare here. Not only are my writing skills lacking, but I can’t see Direct Driller ever making it to the stage either. However, I am questioning the desire to be labelled a “regenerative farmer”. Do you want or need to be labelled at all? This is not quite weighing up life and death, as hamlet does in his soliloquy, but it is important to know what you want to be. Because wants and needs on farms soon become costs and profits.

Understanding your journey is a critical step to profitability and sustainability at a farm level. When I read or listen to our Farmer Focus writers, they often seem clear on this path. This has led the likes of Andy Cato to set up a whole brand and ethos to go alongside their beliefs, allowing other farmers to join them. Tim Parton is part of the Green Farm Collective (not to be confused with Red Tractor’s disastrous Greener Farm Commitment).

They have set out their stall and now have put measures alongside that and you must be able to measure something to make it happen. Now, you can be a Wildfarmed farmer or a GFC farmer,. you can have a label but what is the point of a label unless it benefits your business? These labels can come with benefits. All farmers in the UK can benefit from SFI payments from the government to add biodiversity to their land.

Thus moving them all along a regen journey and that comes with income. There is definitely a reason to make this step but does doing SFI make you a “regen” farmer? Some might say yes, some will say no. For me, it will depend on the farm and farmer, whether they see SFI as part of a wider journey, or just a replacement for BPS.

-

Farmer Focus – Ben Taylor-Davies

January 2024

Neurodiversity and oubaitori, 2 words that presented themselves to me towards the end of 2023, 2 words which answer a lot of questions to many of my life’s struggles, thankfully something that seems to have been put well behind me since finding regenerative agriculture and realising this would cure my mental health issues.

Typically, I had to find the answers to my problems before they found me, however I spend my farming life doing the same. Neurodiversity is now quite incredibly the name given to those suffering from anything on the autism spectrum, ADHD, Dyslexia and or Dyspraxia. As a farmer I have 3 times more chance of being neurodiverse than the rest of the population…. It took me over 30 years to realise this is a good thing and in farming a great thing.

Historically a farming family would have many children, with the academics of the family heading off to the city to work and those with less academic ability to remain home and use their more practical brain to farm. Natural selection then meant this was kept as a trait as farms were handing down through generation after generation.

Farming throughout history was a problem-solving industry, without the ability to reach for packets, cans, bottles, bags and syringes the ability to think laterally was a real asset, this kept these special minds occupied day and night. However, take away the need for the problem solving with the green revolution, a world of advisors and you still have a brain that is hugely active and needs feeding, often with all the things then beyond control and why mental health issues (in my view) is so high in agriculture.

Oubaitori is the Japanese idea that people, like flowers, bloom in their own time and in their individual ways. Education for myself was a struggle, certainly until A levels when my geography teacher Mrs Miles decided to change tac on my teaching and proceeded to bet I couldn’t do something, the result was an A in A level geography and then a BSc in Geography at Liverpool University. However, what I discovered was education for myself only became interesting and exciting when I was learning about something I felt stimulated by.

I think many farmers I speak to have very similar sentiments when it comes to both Neurodiversity and oubaitori, what a great asset to implement a sustainable future for my own farm?! Put my mind to work with something that interests me and with it drive profitability.

Lunchmoney Lewis even sang about them “Bills” something we as farmers need to focus on far more than we do, it’s easy and even lazy just to pile into the agchem industry, yet rarely do I see a pile on into the veterinary industry, insurance, banking, machinery industry and even auctioneer markets, all of which have based their industry extracting what they can from our profits, it’s a real issue and something we are concentrating on at Townsend Farm (Ross-on-Wye) where we farm 220Ha of deep river silt or the red sandstone loam over sandstone the area is most famous for. As I’ve mentioned in so many podcasts, farming is essentially taking 3 free things (Sunlight, precipitation and carbon dioxide, putting them through soil) and making profit, yet somehow, as an industry most farms are in debt…….

Agflation is frightening, my grandfather retired when he bought a Massey Ferguson 135 (which we still own) in 1965 for £885 purely on the basis that he couldn’t see a future fro farming if the cost of a tractor was to go north of £1000. Allowing for inflation the £885 would now equate to £14,283.76, with all the modern technological advances, how much really have we gained? Our Ford 7810 (95hp) during the 90’s ran a 4 furrow auto reset Kverneland plough, it would now seem driving around that between around 200hp seems the norm for a 5 furrow plough – what has gone wrong?

Dopamine is the simple answer, the feel-good drug our body releases as we prepare to and then complete the purchase of a new item “The reward drug” from retail therapy for farmers is often used in the absence of this drug being released if you manage to solve a problem on the farm without using the ‘industry standard’ the latter of course being far cheaper! I am not saying the drive for new technology shouldn’t be sort after, what I am saying is the machinery manufacturers use this dopamine drug to lure you into the showroom and you leave feeling great after parting with a small fortune…

“Intensifying diversity simply” is the 3-word motto of the farm, with the disappearance of BPS and the obvious need to demonstrate to the general public that any money they are being taxed for to give to farmers should be earned for the benefit of everyone as public goods. There seems to be real reluctance to embrace SFI for everything it is along with other schemes aimed at providing support to farms that now offer a financial incentive to protect their main asset (soil) because without this support many are happy to see it literally flow out of the gateway…. Soil is simply like a bank account, if there is less going in than going out you are in debt, when you pass how much debt are you leaving your kin? How many farmers reading this can honestly say they have more soil today than when they began farming? I’ll be brutally honest – definitely not me!

Fighting the bills has become our major focus on the farm, our latest project has been the resurrection of our wind powered water pump which fell into disrepair in the 1960’s and sat there as a relic for so many years, often meaning to push the tower down and send it off for scrap, we now have part A of our energy sustainability project up and running. A FIPL (Farming in protected landscape) grant helped us out a bit towards the cost of having the mill restored and to see the dopamine oozing out of me as the wind turned it as it started pumping water for the first time in 60 years is an understatement, but like anything on the farm this is the just the beginning. The water will be pumped to large storage tanks up at the farm, where of course it will provide water to ourselves and the livestock, but will also feed the solar powered electrolysis unit to split the water into hydrogen and oxygen. The hydrogen to power farm vehicles and the farmhouse heating system and the oxygen used in the compost extraction system. Can we be one of the UK’s first fossil free farms?

The Brewery on the farm is another example of our circular economy way of thinking, produce malting barley, have it malted, sell it to the brewery, use it for 4 hours and then feed the brewers grains to the few Wagyu cattle we now have, combined with their ability to swallow up the waste beer and the introduction of a rotating cattle brush as a massager – will we be producing A5 meat within a few years? Time will tell!

-

Is regen farming producing more nutritious food?

Can how you grow crops impact on the nutrient and health value of food? It’s what farmer and doctor Hannah Fraser is trying to find out on a Nuffield Scholarship

By Mike Abram

For a long time there has been a suspicion that how you grow food will determine its nutrient status and ultimately impact how healthy consumers are. It’s a claim some in the organic farming sector, and more recently regenerative farmers have tried to make but is there evidence to back that up?

That’s what motivated first generation farmer Hannah Fraser to investigate the topic for her Nuffield Scholarship.

“Five years ago, I knew very little about food production,” she says. That was the moment she and her husband Alex took on farming the land around the family home at Denby Hall Farm, near Huddersfield in Yorkshire.

Deciding to farm organically, Hannah and Alex, the pair have embraced practices designed to restore soil health as quickly as possible.

Linking how farmers can impact the health and nutritional value by how they farm was a natural step given Hannah’s day job as a medical doctor at a Leeds hospital.

“I’ve learned a lot working in the medical profession,” she says. “Sadly we have a real issue in this country with chronic diseases, such as diabetes, high blood pressure, dementia and heart disease. They don’t go away easily, often requiring a lot of medication and follow up, impacting quality of life.”

In the UK, she says, just under half the adult population suffers from at least one of these conditions, and while life expectancy is a reasonable 81 years, the age to which we’re expected to live well with no medical problems is only 63.

“What’s more worrying is these numbers are in decline, so our health is potentially getting worse.”

A lot of research shows the importance of food and diet in reducing disease risk, but, while nutritionally dense food is far from a new concept, much less research has been conducted linking how food has been grown to nutrient richness and our health.

There are essentially three components to food that determine nutrient density – macronutrients, micronutrients and phytochemicals.

Macronutrients are the big things – proteins, carbohydrates, fats and fibre, Hannah explains, while micronutrients are the vitamins and minerals present in small amounts. Phytochemicals include thousands of plant-made chemicals, such as beta-carotenes, anthocyanins, phenols and flavonoids.

“Macronutrients often get talked about more in dietary recommendations, but I think it is the micronutrients that can really make a difference to our health. We can’t make these ourselves, so they have to come in our diet.

“In high income countries, where people are relatively calory-secure, just under half of children under the age of five and half of women of reproductive age are deficient in at least one of these micronutrients, so how nutritious our food is could make a real difference.”

Research is also finding phytochemicals have remarkable effects in the body including anti-cancer properties and reducing inflammation, which can be an important component of those chronic conditions.

“It’s why we get told to eat a variety of fruit and veg; eat the rainbow.”

But there are a huge number of unknown phytochemicals in food, which have unknown impacts of our health or how farming systems influence their levels, she adds.

So has the nutritional levels in food declined? Some data suggests it has – a group of scientists compared UK government data between the 1930s and 1980s in 20 vegetable and found 19% lower calcium, 35% less magnesium, 22% iron, 81% copper and 14% less potassium, Hannah says.

“Similar findings have been found in US and Finnish data, although there is criticism of this data. Testing will have improved since the 1930s, and there could have been errors, such as tiny traces of soil left on food which would have made the nutrients levels higher.”

What about testing today’s food and seeing if it varies? That’s what US-based Bionutrient Food Association is hoping could be possible with a handheld device, Hannah says. “To calibrate the device they’ve been taking food samples from across Europe and the US to see how the amount of nutrients varies.”

And the answer is in some foods it can vary a lot. For example, in kale the amount of calcium can vary between 15% and 40% of the recommended daily intake, so at the lower side you would have to eat three times as much to get the same amount of calcium.

The same applies for some other nutrients and vegetables, while similar analysis for polyphenol and antioxidant phytochemicals shows wide variations in some fruit and veg.

“We can’t say what the health impact that is as we don’t know how many phytochemicals you need to be healthy.”

So can we produce more nutrient dense food through changing the way we farm? That’s what those farming using regenerative or organic practices hope, and there is some evidence starting to emerge that might be the case.

Geologist and author David Montgomery and partner Anne Bikle, a biologist, have set up a preliminary trial comparing 10 regenerative farms with conventional counterparts in the USA.

Early trial data suggests, for example with cabbages, the regeneratively farms are producing food with more nutrients. “For vitamin K, 30% more of the amount that you need in a day was in the regenerative cabbage compared with conventional, and 10% more vitamin C.

“In wheat and oats, there was quite substantial differences in mineral content, but it’s just 10 farms so we can’t draw conclusions yet, and shows what a study looks like.”

Other studies have shown higher amounts of ergothioneine, which is produced by fungi and nicknamed the longevity vitamin because it seems to prevent ageing, is found in soybeans and oats produced in a no-till system compared with plough-based establishment.

“It’s an interesting example of how a healthy soil might be providing different compounds,” Hannah suggests.

Or there’s the study showing higher abundance and diversity of beneficial microbes on salad grown in soil compared with grown in a sterile vertical system. These microbes might be helping to populate our gut microbiome, keeping us healthy.

Breeding varieties with higher nutrient density is also possible, as shown by Harvest Plus, a group working in developing countries using conventional breeding to increase iron, vitamin A and zinc in crops.

“Could we breed a wheat that’s high in zinc, iron and copper?” Hannah asks. Already in Finland a programme to apply a foliar selenium fertiliser to wheat has helped solve a deficiency issue in its population.

In livestock agriculture, researchers have found the amount of forage in dairy diets balances the ratio of omega 6 to omega 3 fatty acids in milk to around 1:1 when the animals are fed 100% of forage, compared with 8:1 when there is minimal forage in diets.

This is important as in modern diets we’re consuming around 16 times more omega 6 than omega 3 and scientists think this could be promoting inflammation causing heart attacks, Hannah explains.

“So 1:1 is more in line what might be healthier for us,” she says. “And the same 1:1 ratio has been seen with grass-fed beef compared with 10:1 for cattle finished on a mixed ration.

“There were also a lot more phytochemicals in grass-finished beef.”

Those research findings are giving confidence to Hannah that there is real evidence that different farming techniques can produce healthier, more nutritious food, although more is required and will be needed to convince the public and for policy makers to put in the right incentives for farmers to switch practices.

“We’re in the early days of recognition of the link between farming and health,” she says.

Harking back to a quote in 1943 by Lady Eve Balfour, a British organic farming pioneer, that spoke of the connection between health and correct soil management and the need for any public health system to be connected to soil fertility, Hannah hopes that farmers will be recognised for the important role they play in public health.

“Maybe one day like today when we’re starting to be paid for ecological services, we’ll start to be paid for health services for the role we play in producing nutritious food,” she concludes.

-

Long awaited clarity for carbon accounting tools

After a year-long investigation, Defra’s report: ‘Harmonisation of Carbon Accounting Tools for Agriculture’ is providing much-needed guidance on appropriate standards for carbon reporting.

Direct Driller spoke to Dr Emily Pope from Trinity AgTech to find out what this means for farmers.

A new era for carbon accounting: From the ‘Wild West’ to the ‘Collective Era’

Emily explains that before Defra’s report, the landscape for carbon accounting was unregulated with no clear direction or guidelines.

“Many people called this the ‘Wild West’, however, that era and its financial and environmental futility is shifting to a new era.

“This new ‘Collective Era’ is defined by a movement towards global standards, protocols, rigour, and well executed methods as well as continuous innovation, trust, credibility and collaborative learning.

“All these parameters will help to deliver robust supply chains, environmental progress, and prosperous rural communities,” says Emily.

Detailing the positive implications of this for arable farmers, Emily adds: “We can expect to see farmers and the whole supply chain starting to earn fair and full recognition and reward for trustworthy and credible decision-making that delivers efficient environmental progress in tandem with food production.”

Why assess a farm’s carbon footprint

Emily stresses the inevitability of credible and trusted carbon footprint assessments for all farms, not least because of the increasing attention to the laws and regulations against greenwashing and simple box-ticking. She is also keen to highlight the wider opportunities associated with robust and reliable natural capital navigation.

“The push of carbon footprinting from the supply chain is unavoidable; we’re seeing it increasingly in the livestock sector and other sectors will follow.

“I’m therefore urging farmers keen on better economic and environmental outcomes to remain firmly in the driving seat; this means using reliable software to ensure they have the most accurate data possible, on not only the carbon they emit but also the carbon they sequester,” says Emily.

She explains that there is a big difference in emissions and sequestration.

“All farms have inputs, it’s unavoidable, but they also have trees, hedges, and other natural assets on the farm.

“Often, these environmentally beneficial features are overlooked in carbon accounting.

“This oversight can unfairly portray farms as having a higher environmental impact by focusing solely on inputs and emissions.

“However, natural assets on farms play a crucial role in offsetting the farm’s carbon footprint by absorbing carbon dioxide, essentially mitigating some of the emissions from arable operations,” says Emily.

She adds that recognising and accounting for the positive environmental contributions of maintaining natural habitats on farms is essential.

“This allows farmers to demonstrate the comprehensive environmental stewardship of their operations, challenging the narrow focus on emissions and highlighting their efforts in promoting sustainability.”

If farmers are asked to undertake a carbon assessment, Emily advises that the carbon accounting tool should be critically assessed. “Outdated ‘first generation’ calculators are still being recommend by some businesses, including a few consultants, but these tools produce falsely simplified results that undervalue natural capital assets.”

However, Emily adds that Trinity AgTech’s Sandy is the only tool which complies with the most up-to-date recommendations, as per Defra’s report, and also supports on-farm decision making helping to drive efficiency savings.

“Measuring and benchmarking a farm’s carbon footprint is an important part of decision-making and its value shouldn’t be underestimated.

“By assessing a farm’s carbon footprint on a field-by-field basis, farmers can start to understand what’s driving the footprint and make management changes to lessen it.”

There is evidence that lower carbon footprints are associated with higher efficiencies, which are linked to cost savings.

“In the UK, emissions from arable production are generally between 1 and 4 tonnes of CO2 equivalent per hectare,” says Emily.

She adds that the emissions intensity per tonne of crop produced can vary widely.

For example, emissions from high yielding crops, such as forage crops, can be less than 100 kg of CO2 equivalent per tonne of crop. Whereas emissions from crops with lower yields, such oilseed rape, can be more than 700 kg of CO2 equivalent per tonne.

Without undertaking an assessment, Emily notes that many businesses would be unaware of their output.

Worse still, they could be using a tool which is not fit for purpose, which could potentially be giving unreliable data and misguiding decision making.

Public and private investment around natural capital is also growing, but farmers should consider these opportunities with diligence.

“Farmers could do enormously well for themselves and the supply chain to properly understand the extent and the value of all of their natural capital assets, from carbon through to biodiversity, and be confident in the credibility of their assessments before embarking on any arrangements.

“This is the key to recognising the true value of natural capital using reliable, comprehensive and accurate software.”

Choosing carbon accounting software

Emily explains the landscape of carbon assessment software is complex, but fortunately Defra’s report has finally offered clear guidance and direction.

“Given that farm-level carbon accounting is currently completely unregulated, there is significant divergence in calculation methodology and the resulting information.

“This has reduced trust, stalled environmental efforts, and prevented proper recognition and reward.”

Defra’s report started by reviewing 81 global carbon calculators, analysing in detail the six most relevant and suitable for UK farming.

Reading the report we clearly see that only one tool stood out as being uniquely fit for purpose, Emily explains it was Trinity AgTech’s Sandy.

“This was in part, but not solely, due to Sandy being the only tool to align with the recognised standards recommended within Defra’s report, including ISO 14064:2, ISO 14067 and the draft GHG Protocol Land Sector and Removals guidance, supporting the Science Based Targets Initiative (SBTi),” she says.

Sandy – a new category of carbon accounting software

Having recognised the extreme pitfalls of ‘first generation’ carbon calculators that are often used to assess farm-level carbon, Emily explains that Trinity AgTech has pioneered food and farming’s ‘Smart Precision Navigation’ category of software.

“Sandy is in a complete league of its own and is uniquely positioned for the new ‘Collective Era,” she says.

“This is because the tool is optimised and built from the ground up to focus on continuously delivering increasing value by leveraging cutting-edge proven insights and methods in science, technology, assessment standards, and farming.

“It uniquely provides farmers and key sector stakeholders access to distinctive and relevant science methods, services and platforms that are evidenced, credible and trusted, adding value throughout the supply chain.”

She highlights that this development represents a significant leap forward in agricultural technology.

“By focusing on smart precision, continuous innovation, and comprehensively addressing the complexities of modern agriculture, we’re not just keeping pace with the times and the assessment protocols – we are delivering a new standard for the future.”

Questions to ask before choosing carbon accounting software

If farmers are asked to use a specific carbon accounting tool, Emily encourages them to ask the following questions to ensure the enterprise is not being penalised and disadvantaged:

- Does it align with the standards recommended within Defra’s report, these are ISO standards 14064:2 and 14067 and the draft GHG Protocol Land Sector and Removals guidance which is supportive of the Science Based Targets initiative (SBTi)? This is a must to produce trusted and reliable data.

- What data is required and how does the tool handle assumptions? This effects the accuracy of the output and the ability to identify specific areas for emissions reductions.

- Does the tool provide guidance and support for understanding and interpreting results? Given the complexity of carbon accounting, the tool must offer clear support to enable farmers to make informed decisions about reducing emissions and enhancing carbon sequestration on farm.

- Handling of low carbon fertilisers: the Defra report discusses the complexity of emission factors and how they vary between calculators, particularly with manufactured fertiliser and organic manures.

- Does the tool fully represent the farm’s activities: a tool should comprehensively represent all farm activities, including emissions and sequestration.

- Does it allow for carbon sequestration on the farm? For example, all the great natural habitats and features which are absorbing carbon such as trees, hedgerows and permanent pasture.

- Does it have the capability to account for natural capital assets beyond carbon, such as biodiversity, soil health and water quality? These assets also hold significant value.

- Does it offer scenario planning functionality? This can help plan decision making and reduces the risk of management changes.

Sandy demonstrations available this summer

Trinity will be offering Sandy demonstrations at several shows and events this summer.

- Scottish Land & Estates Annual Conference 2024, Tuesday 21 May

- Green Farm Collective Regenerative Agriculture Conference 2024, Wednesday 22 May

- The Suffolk Show, 29 & 30 May 2024

- Groundswell, 26 & 27 June 2024

Farmer case study: Michael Kavanagh, Church Farm

First-generation Shropshire farmer and founder of the Green Farm Collective, Michael Kavanagh, explains how he set out to create a sustainable and profitable business using regenerative farming principles when he began farming at Church Farm eight years ago.

“After starting out using a strip-till system, I became interested in soil health which led me to consider how I could farm sustainably without using off-the-shelf chemicals.

“I realised that there was another way to farm as opposed to the conventional practices I’d always followed,” says Michael.

The farm now follows a zero-till system; insecticides and plant growth regulators are no longer being used and in the last two years only one fungicide has been used across the entire farm.

However, he notes that if the ground isn’t ready for no-till then the results will be affected.

“For example, on a large area of new land we’ve stepped back to strip till because the land is simply not ready for a zero till system.

“Implementing a zero till system wherever possible is a big change. By not moving the soil, we’re keeping all the carbon locked in, with no impact on yields.

“Church Farm is also really pushing the boundaries of what’s possible with on-farm changes including zero use of P & K bagged fertiliser,” says Michael.

“We’ve also minimised our fuel usage as a result of zero till. During drilling, we’ve been using around five litres of fuel per hectare which is a miniscule amount for on-farm work.

“Nitrogen use efficiency has been hugely improved through the work we’ve been doing on farm.

“Nitrogen is one of the biggest killers on carbon calculations, so being able to improve the efficiency of this has been a great achievement.

“We’ve also extended our rotation and included cover crops which has demonstrated huge benefits.”

Michael explains that as part of the Green Farm Collective, he was looking for a partner to be able to quantify the work they were doing to improve their sustainability.

“We knew we were doing the right things on-farm, in terms of carbon and biodiversity, but wanted to be able to quantify it.

“We explored various options and Trinity AgTech had the best understanding of the practices we’d adopted and the most robust science and analytics in Sandy.

“The agriculture sector is in pioneering times at the moment and there’s going to be a lot of change in the coming years, so it was important to find a navigator we could rely on and trust.”

Key recommendations from Defra’s Harmonisation of Carbon Accounting Tools for Agriculture report

Defra’s recommendations for supporting the harmonisation of farm-level carbon accounting are as follows:

1. Industry and HMG to clearly define what a farm-level assessment is, how it is going to be used, and what parts of a farm business should and should not be included.

2. Calculators to align with the requirements of the latest standards and guidance – currently GHG Protocol standards (including the upcoming Land Sector and Removals guidance), ISO 14064 and ISO 14067. Industry and HMG to provide guidelines to support a standardized way of applying these in an agricultural context.

3. Calculator providers to regularly review and update calculators to account for changes in scientific knowledge, carbon accounting methodologies and new emission factors.

4. Calculators to comply with the latest IPCC guidance (currently IPCC 2019) and use those calculations and emission factors as defaults where Tier I approaches are used. Where appropriate, calculators to use Tier II and Tier III calculations where robust emission factors and methodologies are available, such as emission factors created for the UK GHG Inventory.

5. Calculators to use emission factors from an agreed set of robust databases for embedded emissions in fertilisers, feeds and fuels. Industry to support the development of appropriate emission factors for embedded emissions in purchased livestock.

6. Calculators to present outputs in compliance with the latest standards. Industry and HMG to define consistent disaggregated output categories for use by all calculators to facilitate understanding of emission sources.

7. Calculator providers to build user confidence through transparency of approach and third-party verification of the alignment of calculators to minimum standards

-

Farmer Focus – Tim Parton

February 2024

Water, water everywhere! I bet it turns off just when we need it!

What an Autumn/Winter! The rain keeps coming, which makes you wonder if it will turn off just when we rely on it. On a positive, it is wonderful to see how well my soil copes with these extremes, with fantastic infiltration rates and organic matter levels rising yearly, I can store a lot more water than I used to, which was always one of my aims.

At the time of writing, we have just had yet another storm, which on a positive gives me the time to go and speak at the Scottish Agronomy Technical Conference (there is always a positive, we just have to look for it). To date I have applied some calcium to winter crops, as calcium is the King of nutrients to me and is often overlooked and compared with pH – pH being potential hydrogen. Plants are weak and open to disease when calcium levels are low due to bacterial and fungal attack. It is needed for cell signalling, cell division and cell wall strength. Roots will cease to develop without calcium and if you have a low fungal soil, it can be sign of low calcium, which is why it is so important and why I refer to it as the King of nutrients! Calcium is also the carrier for many other nutrients.

The farm looks very well overall, with lots of potential going forward, but as we all know, things can change so quickly with the weather patterns we are now having to contend with. We have joined the SFI as it brings a nice income onto the farm which is gratefully received. It saddens me to hear many farmers looking at it as just another subsidy and only doing the bare minimum to obtain the cash or looking to put a legume fallow in the Spring, knowing full well it won’t meet the requirements of the scheme. Wherever I speak in the world this scheme is envied by conservation regenerative farmers: the fact that we are being paid to improve the health of our soil, which is any farmers most valuable asset, should be applauded in my opinion. It is quite ironic for me that I always set out to be able to farm without subsidy, when now I am being rewarded for the way I wanted to farm all along. I am not a fan of farmers being encouraged not to farm, as I feel it is such an oxymoron to give ourselves a pat on the back at how green we are being, only to import our food from another country! Robbing their water and resources in order to meet our demand for food, plus the carbon footprint in getting the food here. I have proved that I can still produce food, of better quality than what is imported, I might add! While healing the planet in which we live, putting the carbon back where it should be stored in our soil, to feed the underground livestock. By not producing our own food is just moving the problem elsewhere and we should be hanging our heads in shame at that.

Wood Vinegar will be featuring a lot in my application programme going forward, as it is a fantastic carbon source, which I have seen to improve root growth, leaf etc. Care has to be taken on rates, as it is with all products, balance is everything. What I have seen so far is very encouraging and I will be running more trials this coming season! Trials are always the way forward, as I like actual results and returns before rolling out across the whole farm.

I have had a very busy Winter (Winter used to be a time to replenish my energy levels for the coming year) speaking the length of the UK, which I have thoroughly enjoyed and met some fantastic farmers and people. My website https://www.timpartonfarming.com/ has members from around the globe and is keeping me busy answering questions and helping people on their journey of discovery in the wonderful world of conservation regen agriculture. We all have so much to learn, but farmers have very similar problems wherever they are on the planet.

We have had a very busy few months within the Green Farm Collective, putting together biodiversity/carbon deals and the one where we have been focusing a lot is to be able to sell certified regen produce. This has taken a great deal of work and one which we are very proud of, with our first load of wheat due to leave very shortly, giving at least a £20/ton premium back to our members, be it milling or feed wheat. We are now starting to focus on malting barley as we are having Maltsters getting in touch with us. Demand is escalating, but I would urge everybody to stand together on this one as we deserve a premium for our produce when we are doing so much good for the planet in which we live. I find once you explain the story behind Regenerative Agriculture people want to buy in and be part of that story and will happily pay an extra five pence on a loaf of bread; but the story needs to be told and the produce has to be genuine, otherwise it will get swallowed up and spat out with no premium to the farmer and no achievement for the planet in which we live. It will all just become green washing! This is why we have a set definition within our membership of what Conservation Regenerative Agriculture is and one which will be added to, in order to achieve the ultimate, regenerative planet.

Green Farm Collective have our annual open day on May 22nd which is free to members, and any non-members who want to attend can purchase tickets (see the advertisement within Direct Driller). We have a great line up of speakers and will be updating attendees on our progress with sales of produce, carbon and natural capital.

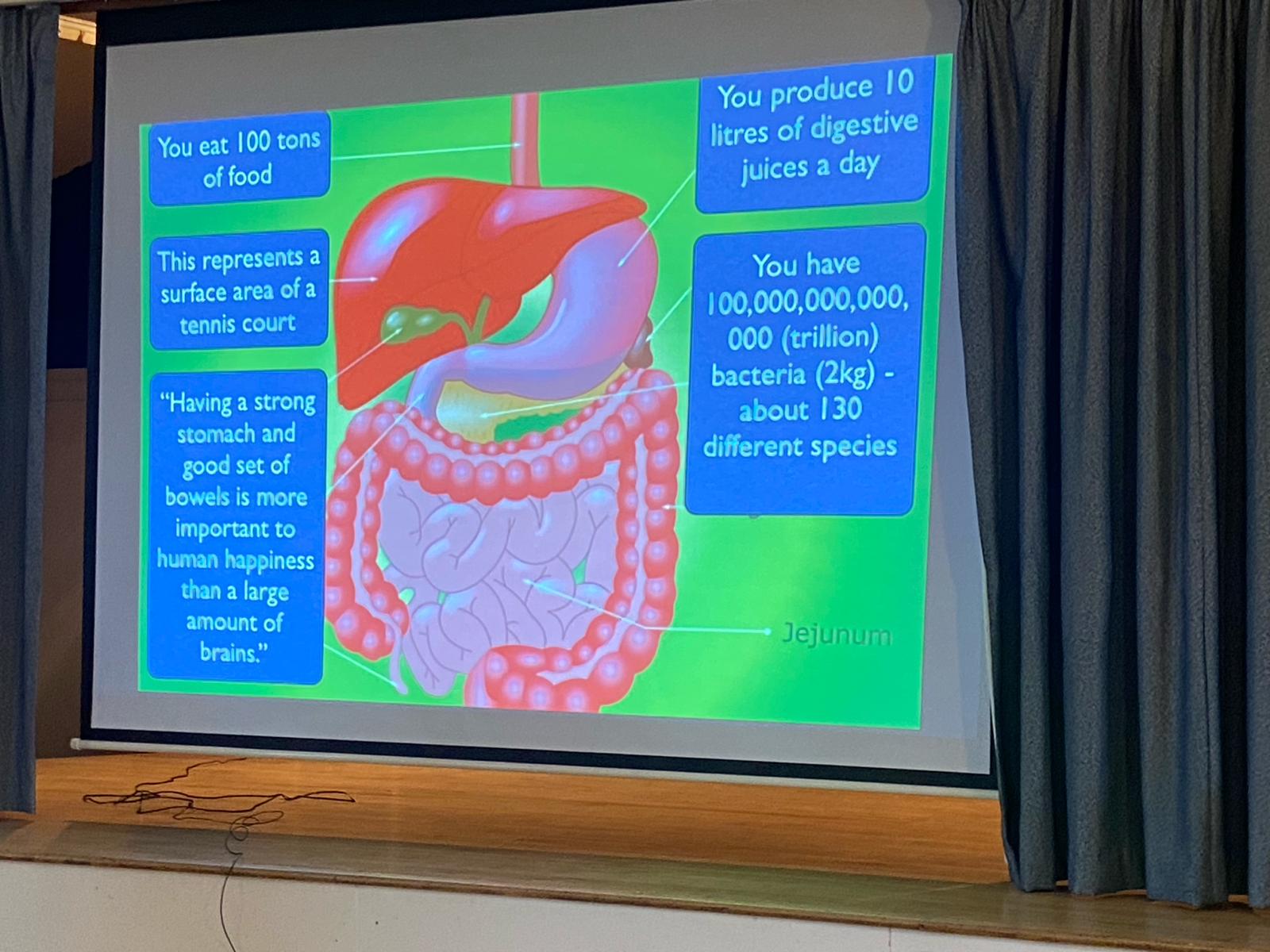

On a last note, we organised a great workshop with Dan Kittridge from the Bionutrient Food Association and Patrick Holford, founder of the Institute of Optimum Nutrition.

Dan spoke in the morning, talking about his work with the Bio-meter which measures the nutrient richness of the food we have produced. He had some fantastic results with the main theme being that a healthy soil produced the best food, regardless of the system, which all comes back to the microbes within and keeping them well fed: healthy soil is everything. The other interesting results were from beef produced of herbal leys, which produced by far the best meat, compared to cereal fed beef. To me, this is just common sense, as ruminants were never designed to eat cereals, which is why they burp and fart such a lot when being fed a cereal ration. as they have so much indigestion. Whereas a nice herbal ley gives the animal so much choice, that they can get the nutrients they desire in order to keep themselves healthy and at peak production, with that health then being passed onto us. My family and I have been eating grass fed beef for many years now, which I buy from a good friend of mine, Martin Howard from Northcote Farm in Devon, which arrives in perfect condition, frozen, with next day delivery. Nothing beats the taste.

Patrick Holford spoke in the afternoon. He has helped many people including me with mental and physical conditions over the years using nutrition. He spoke on the prevention of Alzheimer’s and dementia, which was a fascinating talk, making the connections with healthy soil, as food should be thy medicine. Like me, Patrick recommends supplementing nutrition with additional supplements, when disease is present, to help the body heal, as sometimes we just cannot eat enough nutrient rich food. This is exactly what I have found within soil, that sometimes the plant cannot get enough of one particular element, which is where sap testing comes in handy, so that I cannot only monitor levels, but also get the plant to the required elemental amounts, in order for me to keep the plant healthy and free from disease, but sometimes high rates are required to achieve the objective.

-

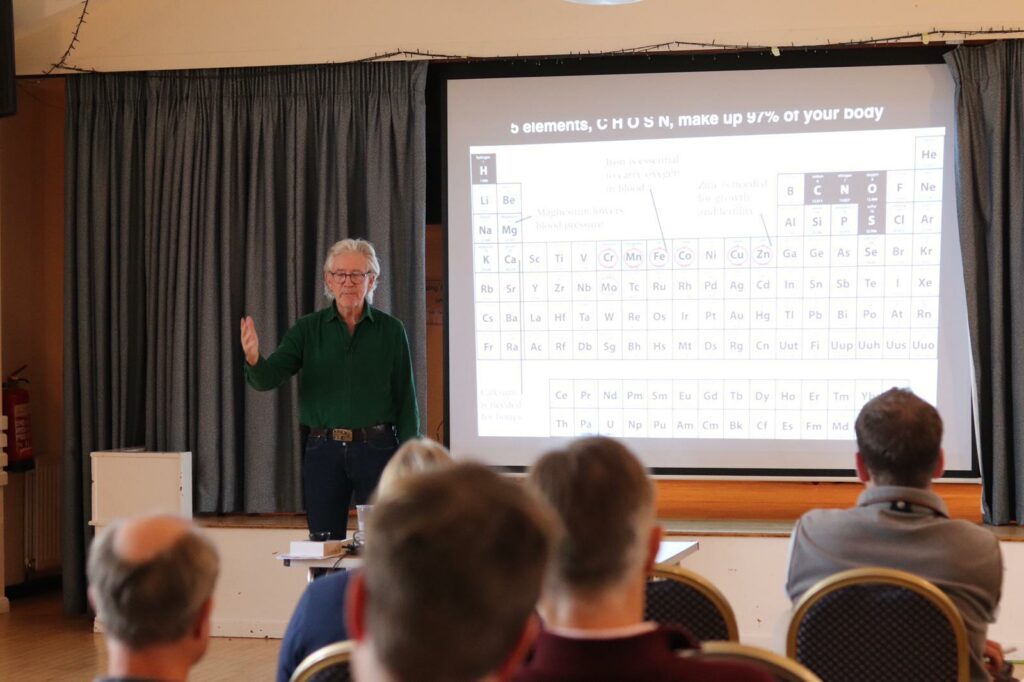

A sky-high revolution in crop research.

Drone technology is poised to bring about a significant transformation in crop research in the coming years, according to leading agronomy company Agrii. This technology has the potential to not only enhance the capacity of plot assessments traditionally conducted by researchers but also to improve the consistency of results across all Agrii trial sites throughout the UK.

Dr Ruth Mann, head of research and development for Agrii, has been looking for disruptive innovation in field research trials for some time. “Assessments are completed in exactly the same way as they were when I was first involved in small plot trials work over 30 years ago. New technologies are providing opportunities to move this approach forward considerably,” says Dr Mann.

Trials depend on researchers to collect in-season data on a range of factors like plant counts and NDVI. Given that most research sites extend to several thousand plots, this process is not only time-consuming and labour-intensive but also prone to subjectivity, leading to potential discrepancies in results among researchers.

Agrii has been actively working with specialists at Drone Ag and heliguyTM to explore the potential of drone technology in their R&D programme. Leading this research is Jonathan Trotter, the technology trials manager at Agrii.

Dr Ruth Mann, head of research and development for Agrii “Agrii operates 40,000 trial plots at sites across the UK,” says Jonathan. “Each of those plots requires different assessments at different times of the year according to the requirements of the trial. This is a huge logistical effort.”

Dr Mann adds: “These assessments are subjective as they are completed by researchers with their innate biases. If we can complete these assessments objectively using software, we can remove any variability among researchers, resulting in data which are comparable across the country. This provides further enhanced technical backup for all products marketed by Agrii.”

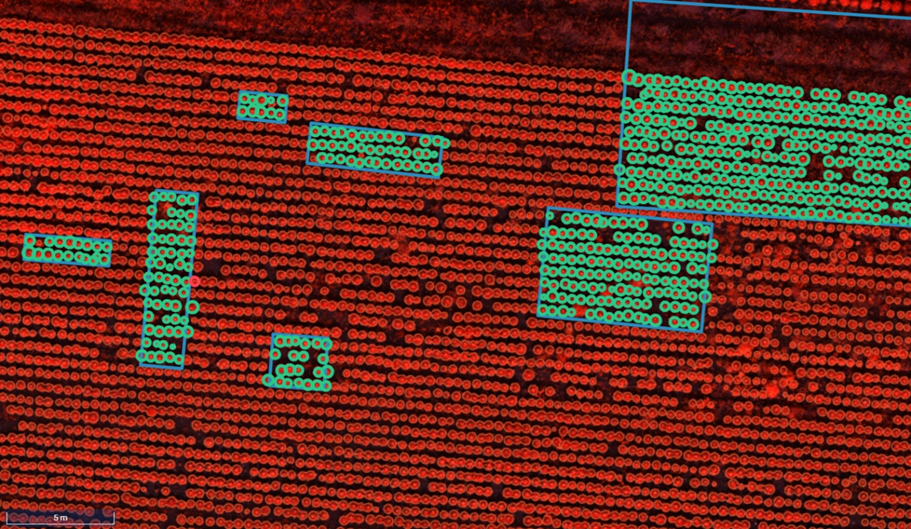

Drones will not be able to replace every trial assessment, so Jonathan has focused his work on analysing which are most readily replaced. To do this, he conducted trial assessments using a drone and compared the results with the data collected by a researcher.

“One example of work that can be replaced by a drone is cabbage plant counts and head sizes. I flew the trial several times with a drone to collect the data and then sent someone out to ground-truth that reading. Most of the time, the drone gave the precise cabbage size; at worst, it was only two centimetres out.

“These data points were gathered using the photogrammetry method. The drone maps the trial with hundreds or thousands of high-resolution images that are stitched together for analysis. The downside is that it requires a lot of data and takes a long time to process,” explains Jonathan.

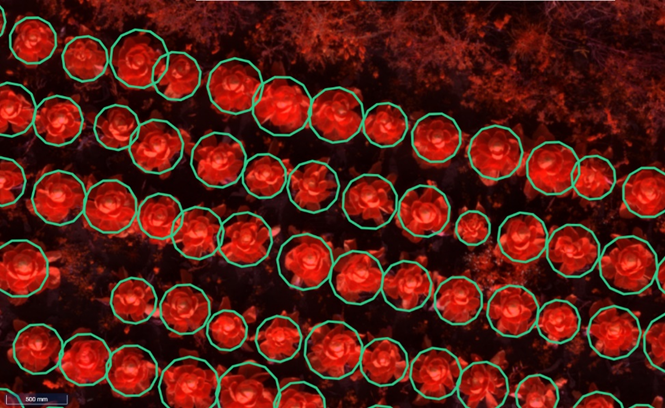

AI in action – this is post processing and what the AI has counted / not counted. New drone tech moving things forward

An alternative method uses Drone Ag’s Skippy Scout platform. Currently, this is used to aid agronomy and decision-making in commercial fields rather than R&D. Scout points are identified across a field, and data are collected from them, which helps build a more complete picture for agronomists and farmers. Agrii is collaborating with Drone Ag to use this technology and their A.I. in trial plots.

“Our custom flight control technology allows a drone to take detailed low-level images of each plot,” describes Jack Wrangham, director of DroneAg. “It will speed up the process of assessing trials because there will be no need to stitch together many images like with the photogrammetry method.”

The Skippy Scout system will allow the researcher to assess multiple fixed points per plot. The drone will return to the same point for subsequent assessments. The Skippy Scout method should also allow a greater range of assessments to be conducted by drones.

“Having the drone closer to the plot gives much more detail to the imagery. Photogrammetry is very good for detecting differences between plots, but it still requires ground-truthing by a person to analyse what the difference is attributed to. The Skippy Scout system does 95% of this.

“It should reduce much of the labour required to run trials and can help target where a researcher needs to check a trial by flagging specific plots that would benefit from checking,” adds Jack.

Fully automated flight on the horizon

The game-changing development for using drones in R & D will be if they become fully automated. This would enable drones to conduct many more assessments than has ever been possible, all carried out on a fixed schedule without needing a human to be present at the trial site.

“In a fungicide trial, we currently do disease assessments perhaps three times in the critical spring period,” says Jonathan. “If you really wanted to, you could fly every hour of every day to detect things we are currently missing.”

The technology is capable of unmanned and beyond visual line of sight (BVLOS) operations, but current UK regulation restricts its use. Agrii is working with heliguyTM, a leading drone retailer, consultancy and training provider, to help build the case for BVLOS use.

“At the minute, the regulation is pretty limited in the UK,” says Mark Blaney, head of training at leading drone retailer and training provider Heliguy. “Recently, the Civil Aviation Authority (CAA) has announced a ‘regulatory sandbox’. They have appealed for stakeholders to come forward to participate in a trial test of their proposed regulation to allow BVLOS.

“Companies will have to build up a use case with evidence of safe automated drone use to get authorisation from the CAA, which Agrii has been doing with their existing work.”

“Bringing together the skill sets in these three companies will lead to long-awaited innovation in field trials. Enhancing data collection methods beyond traditional photogrammetry techniques by using the advanced analytics of Skippy Scout and combining this with full autonomy will increase the value of the trials Agrii complete across the UK and reduce the monotonous field assessments that need to be completed by highly qualified researchers,” concludes Dr Mann.

-

Farmer Focus – Anna Jackson

March 2024

February is supposed to be quiet?

For those that I haven’t met before, hello, my name is Anna and I’m 4 years into farming. I grew up on our family farm but made the move to return 4 years ago and haven’t looked back since. You may have met my Dad, Andrew Jackson, as he occasionally writes articles here too. DD asked me to write an article because I’ve got quite a few projects going on at the moment that are making my February bloody busy and reducing my hours sitting on the sofa with a cuppa.

First off we are coming up to lambing and for the first time ever we are going pasture fed only and lambing outside, a very terrifying prospect for me. We’ve always bought around £1000 worth of nuts to keep the sheep in good health ready for lambing. However, this year I have direct drilled 90 acres of grass which can happily keep my 74 sheep fed until lambing, if anything we have too much grass. After my sheep have come off this grass it will be used for outdoor pigs. This means I have to anxiously wait until the 15th of March to see how it all goes and in the meantime compared to last year where I was feeding them every day, this year all I have to do is top up their mineral bar once a month and check on them daily. I feel rather helpless but also a little smug as I’ve managed to reduce my workload.

The next adventure is drilling our ‘boats’, beans and oats. This is all very new to me, I am the drill person on the farm. A job I absolutely love, we have a Horizon drill. However, I have never drilled boats before, a mixture of oats and beans. On the farm it is usually me who persuades Dad to try new ideas and sometimes I can work at him for a good 6 months until he says yes. I tend to go for a really crazy idea first then I’ll slowly make it more realistic. However after fighting for boats, I didn’t expect him to say yes straight away. So now I have to figure out the seed depth, which hoppers to use and fit that all around finding a weather window (near impossible with all of this rain we’ve had). Plus harvest. I’m really excited to see how we get on and I’ve promised Dad I’ll just do a trail field (or two). So watch this space we will either be harvesting very green beans or very green oats.

I’ve been working with the Future Food Movement to help put a face to farming. They basically start conversations happening between the supply chain and farmers. The idea is that they ask about our harvest and how it went, how much money we took/lost and basically how it’s going on our end. This isn’t a project that’s going to change the food system overnight but I’m hoping by chatting to them face to face we might start making steps to increase food prices and help them understand what is actually happening on the ground. So far I’ve also met some great farmers through this initiative such as Flavian Obiero (@thekenyanpigfarmer). I will keep chatting and keeping an open conversation, hoping for change.

Volunteer crops have always interested me. The idea that a crop falls out of the back of the combine and grows in the most harshest of environments. It just kind of made sense to me to have a play with them so I am trailing volunteer Oil Seed Rape with 0 inputs because that way if the crop fails at least I haven’t put any money into it. We feel more confident going into this as we are being advised by RegenBen (Ben Taylor Davies). So far I’ve let the volunteers grow and grow they did! We have way too much coverage. Then I hard grazed it with sheep and they munched the crop right down to little stumps. Then the weather gods decided to partly flood the field which was lovely, luckily because we’ve been no till for 4 years or so it wasn’t too bad. And now it’s starting to grow again mainly with little off shoots on the munched down stems. But the most interesting part to me is that the roots are growing directly down however last year with the rape crop that we direct drilled the roots were horizontal and basically on the surface. I had a chat with Tim Parton about this and he said it’s because we put N on straight away last year and the rape roots are lazy so it wouldn’t have been bothered to root down. So much food for thought (pun intended). So currently we are still using no inputs, even though our agronomist is getting nervous, and we plan to just see what happens… hopefully finishing with a harvest.

We’ve spent the winter putting up fencing around our farm so that we can graze it all with sheep eventually, the fences make it easier to move sheep on and off quickly. We managed one third of the farm this year with outside help. I thoroughly enjoyed the mini trailer we borrowed because I could wizz around on it so easily, it’s the little things. This year we’ve managed to graze our grass (for seed) which has a clover companion crop and the clover really needed munching down. We accidentally had sheep on the rape, some of them were very good escape arists, so we will see how that turns out. But our aim for next year is to put them on wheat and cover crops. I’ve been learning from Ed Horton (@e.a.horton) who has been putting sheep on his crop to reduce disease and has had some really promising outcomes. The final bit of fencing we need to finish this year is getting my sheep into some woodland because I believe ivy does wonders for sheep if they are in a bit of a pickle medically, this is a project I’m extremely excited about.

-

BYDV-Resistant Wheat

BYDV-resistant wheat is a relatively new concept in the UK that is creating significant interest among farmers and the seed trade.

Pressure from BYDV is building after the ban in 2019 of seed treatments that controlled the aphid vectors, while resistance to insecticide sprays is increasing and government policy on insecticide use is tightening.

Concern is not just confined to the traditional BYDV disease hotspots. Sub-clinical levels of the disease can also shave yields and erode returns.

Overall, annual yield losses in untreated crops average 8%, according to AHDB figures, but can reach 60%. And it is estimated that 82% of the UK’s wheat crop area is at risk from BYDV.

Clive Bailye is managing partner of TWB Farms, near Lichfield, a zero-till operation consisting of owned land, FBT and contract farming arrangements over several hundred hectares.

Clive Bailye and Martyn Allen from TWB Farms Whilst Staffordshire is not a high-pressure BYDV area, Clive suspects the farm’s wheat crops have been leaking yield.

“I haven’t sprayed insecticides for 16 years, but it would be very naive of me to say that we’ve never had BYDV since then,” says Clive. “We’ve not had any noticeable disease symptoms or yield loss, even in bad BYDV years, but in any given season sub-clinical levels of disease have probably been present in certain fields.

“That may well be costing me a couple of percent of yield, and that’s one reason why I’m keen to find out more about BYDV-resistant wheat varieties.

“The other reason is I want to maintain my no-insecticide policy at all costs. Whenever we use these synthetic products, or use unnatural techniques such as cultivation, we upset a balance. It might solve one problem but we could be creating another – there are consequences.

“Insecticides are more damaging to beneficials than most of us farmers realise. It becomes pretty obvious when you stop using them; on this farm, natural predators have increased in number to the point that they are doing the job for us.”

Clive believes the farm’s move to no-till, which began in earnest 16 years ago, is the reason why his no-insecticide policy has been so successful – visibly at least.

The move was initially a hard-nosed business decision, to reduce fixed costs and speed up operations as the farmed area expanded. However, it wasn’t long before Clive started noticing improvements in soil structure; fields were travelling better, creating wider operating windows, and plants benefited from the more friable soils.

“We stepped up our cover cropping, keeping soil covered with plants year-round, and introduced a more diverse rotation. We took the decision to improve soil and try to grow bigger yields whilst reducing dependence on synthetic inputs.

“But we never made a conscious decision to stop using insecticides. We had used them regularly in the past – it was cheap insurance. When we became more aware of the soil food web and how everything interacted, we decided not to use insecticides routinely, only if we had a problem.

“By the time we got to 2012, we realised that we hadn’t used an insecticide for over a year. We hadn’t had the need, and we still harvested decent yields. Was that luck? Rather than find out, we looked at what we could do to improve our chances of not having to reach for that insecticide can again.

“We were creating this more natural environment where nature was more in balance. It’s not perfect, of course, but we weren’t getting those extremes of problems.”

Clive admits that being in a low-pressure BYDV area will have helped. Despite that, he is now seriously considering what BYDV resistant wheats can do for his business.

“I only grow wheats that are resistant to orange wheat blossom midge, and adopting BYDV-resistant varieties is the obvious next step. It is exciting technology that comes at very little cost, especially when you consider that we can now claim £45/ha on land managed without insecticides. Suddenly that insecticide doesn’t look so cheap any more – there’s a significant opportunity cost.

“We also know that pyrethroids used to control aphids are less effective than they used to be. And, when you look at the direction of agricultural policy, it’s obvious that pressure on their use will increase. It’s probably only a matter of time before we will rely on resistant varieties to control BYDV.”

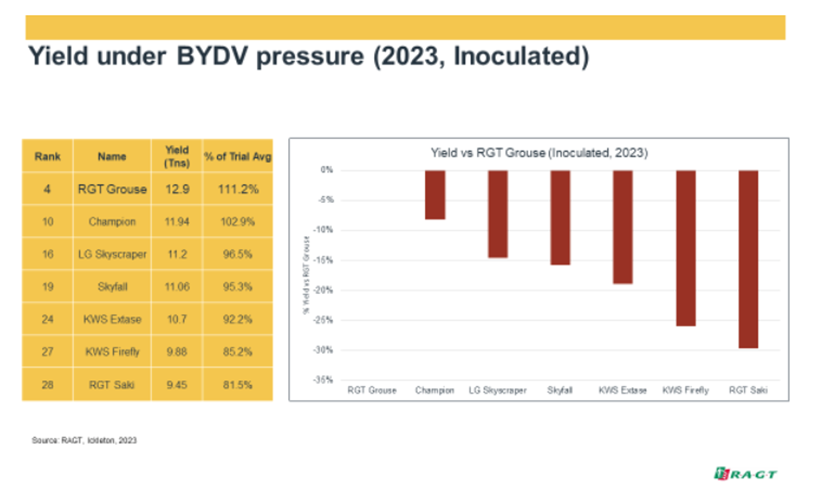

Clive is growing 15ha of RGT Grouse this season as a “look-see”, a high-yielding Group 4-type wheat with BYDV resistance. He will assess its performance over the weighbridge, along with an adjacent field of Dawsum and a further one containing a four-way blend of feed wheats, none of which are resistant to the disease.

All will receive the same inputs. “This will give us some idea of the relative performance of the wheats on this farm in a no-insecticide system,” says Clive, who will use ADAS Agronomics tramline trial metrics to analyse the results.

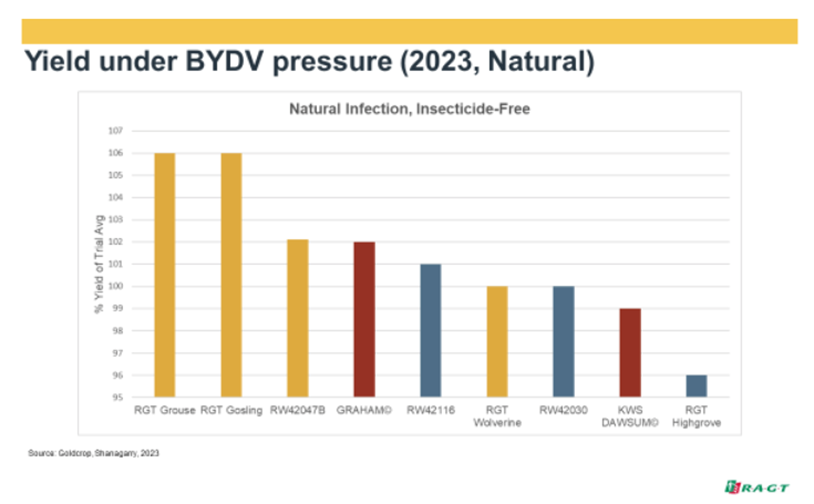

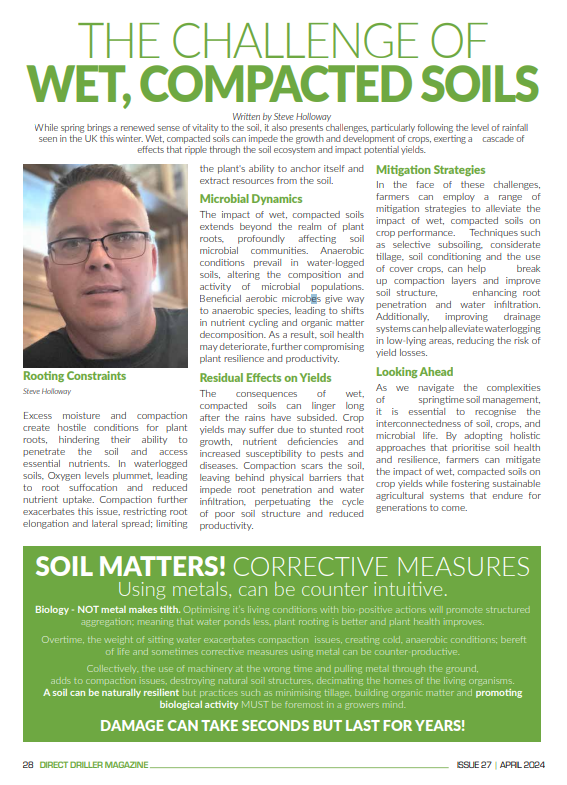

“We’ll take out a 3ha block in the middle of each field, which should minimise any variation on what are fairly uniform fields. Of course, it might be that it happens to be a good Dawsum year or a good Grouse year, but it will still be valuable to see how these varieties respond.”