There are new payments to encourage the uptake of precision farming, and increasingly powerful platforms to implement it. Steve Butler, Agrovista precision specialist, examines some of the benefits on offer.

Precision farming has been gaining traction on UK farms for the past 20 years, aiding crop production, farm efficiency, grower knowledge and ultimately, business profitability.

One of the key contributors that has helped increase the speed of uptake over the past decade has been variable rate (VR) technology, thanks to improvements in data collection and interpretation as well as ongoing advances in application technology.

As such, VR has become a proven practical tool that is no longer an overly complex or expensive addition to farming practices.

The introduction later this year of Sustainable Farming Incentive (SFI) payments for VR applications, along with Farming Equipment and Technology Fund (FETF) grants to help with the cost of equipment, make it even more attractive.

This, and the fact that an ever-growing number of farms have access to VR machinery, is likely to encourage a further significant uplift in the number of growers using VR.

SFI payments are worth £27/ha/year, where “VR application technology is used to apply nutrients on arable, horticultural land or improved permanent grassland, to match the nutrient needs of crops in different areas within land parcels”. This provides a fixed-cost benefit against the variable costs of nutrients even before growers know the extent of nutrient variation across their land.

The ability to apply key nutrients, such as nitrogen, phosphorus, potassium, manganese and lime, as well as seed, to match crop demand helps make more efficient use of targeted inputs. This can lead to higher yields and more even crops, creating further efficiencies with fungicides and herbicides, helping fields perform nearer to their true potential.

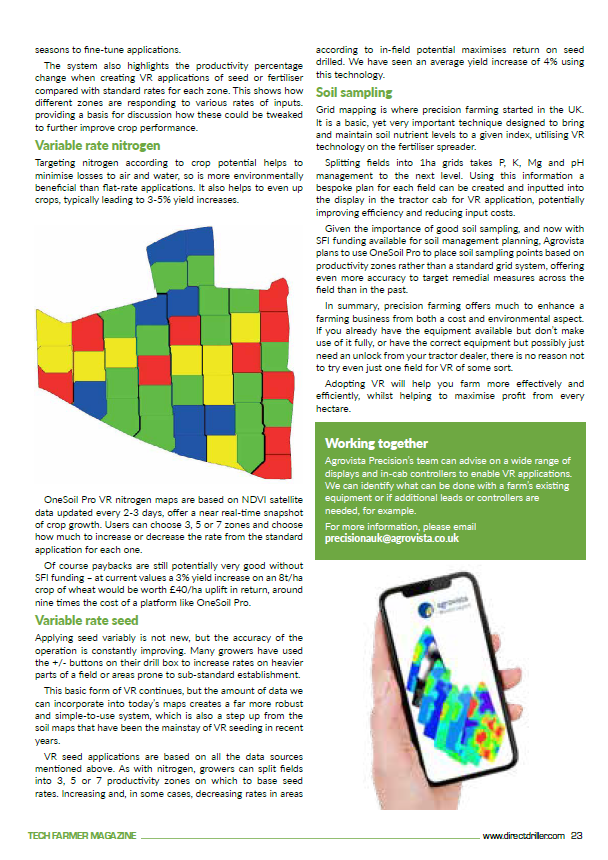

Of course, the field maps required for VR are only as good as the data used to make them. Advanced software, such as OneSoil Pro now on offer from Agrovista, processes up to seven years of existing satellite imagery to analyse individual fields.

This takes into account NDVI (vegetation index), soil brightness (soil type) and elevation. The data is then crunched, dividing the field into zones based on crop productivity potential.

Yield maps can also be uploaded to enable the software to generate a yield report for the different zones, to aid decision making further.

Control strips can also be established automatically within separate productivity zones, enabling growers to assess the effect of different input rates on crop yields over several seasons to fine-tune applications.

The system also highlights the productivity percentage change when creating VR applications of seed or fertiliser compared with standard rates for each zone. This shows how different zones are responding to various rates of inputs. providing a basis for discussion how these could be tweaked to further improve crop performance.

Variable rate nitrogen

Targeting nitrogen according to crop potential helps to minimise losses to air and water, so is more environmentally beneficial than flat-rate applications. It also helps to even up crops, typically leading to 3-5% yield increases.

OneSoil Pro VR nitrogen maps are based on NDVI satellite data updated every 2-3 days, offer a near real-time snapshot of crop growth. Users can choose 3, 5 or 7 zones and choose how much to increase or decrease the rate from the standard application for each one.

Of course paybacks are still potentially very good without SFI funding – at current values a 3% yield increase on an 8t/ha crop of wheat would be worth £40/ha uplift in return, around nine times the cost of a platform like OneSoil Pro.

Variable rate seed

Applying seed variably is not new, but the accuracy of the operation is constantly improving. Many growers have used the +/- buttons on their drill box to increase rates on heavier parts of a field or areas prone to sub-standard establishment.

This basic form of VR continues, but the amount of data we can incorporate into today’s maps creates a far more robust and simple-to-use system, which is also a step up from the soil maps that have been the mainstay of VR seeding in recent years.

VR seed applications are based on all the data sources mentioned above. As with nitrogen, growers can split fields into 3, 5 or 7 productivity zones on which to base seed rates. Increasing and, in some cases, decreasing rates in areas according to in-field potential maximises return on seed drilled. We have seen an average yield increase of 4% using this technology.

Soil sampling

Grid mapping is where precision farming started in the UK. It is a basic, yet very important technique designed to bring and maintain soil nutrient levels to a given index, utilising VR technology on the fertiliser spreader.

Splitting fields into 1ha grids takes P, K, Mg and pH management to the next level. Using this information a bespoke plan for each field can be created and inputted into the display in the tractor cab for VR application, potentially improving efficiency and reducing input costs.

Given the importance of good soil sampling, and now with SFI funding available for soil management planning, Agrovista plans to use OneSoil Pro to place soil sampling points based on productivity zones rather than a standard grid system, offering even more accuracy to target remedial measures across the field than in the past.

In summary, precision farming offers much to enhance a farming business from both a cost and environmental aspect. If you already have the equipment available but don’t make use of it fully, or have the correct equipment but possibly just need an unlock from your tractor dealer, there is no reason not to try even just one field for VR of some sort.

Adopting VR will help you farm more effectively and efficiently, whilst helping to maximise profit from every hectare.

Working together

Agrovista Precision’s team can advise on a wide range of displays and in-cab controllers to enable VR applications. We can identify what can be done with a farm’s existing equipment or if additional leads or controllers are needed, for example.

For more information, please email precisionauk@agrovista.co.uk or call our dedicated support line 0115 921 8453.