In a particularly challenging season for field operations, Amazone’s David Thomason considers how new tech can help get the job done.

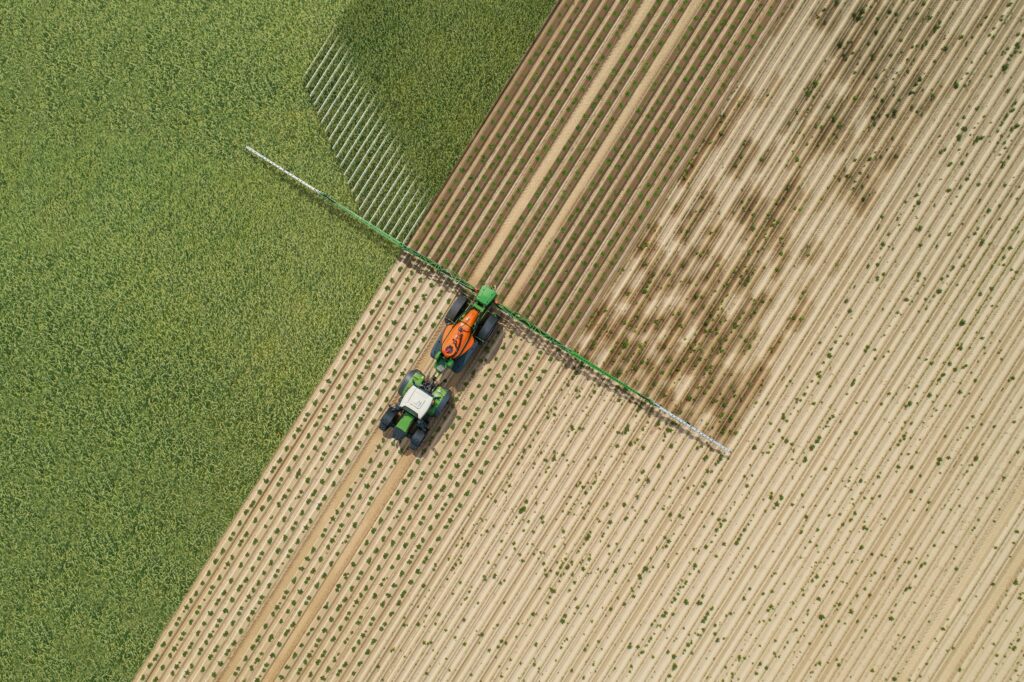

In a constant battle with the British weather, growers are always on the lookout for spraying solutions to get the job done in a timelier manner, and this season has been a case in point. A plethora of storms have plagued field operations and have left many fields impassable for a significant period of the 2023/24 growing season, with a large proportion of farmers holding out for a drier spring drilling period. For crops that are established, the struggle now begins with getting onto these fields without causing irreparable damage – it’s where a well thought-out spraying outfit helps to get you through without a hiccup.

New sprayers are getting bigger, and while Amazone strives to keep weight down, we also focus on optimising weight distribution. The new self-propelled Amazone Pantera 7004 brings the Pantera 4504 from a volume of 4720 litres up to 7000 litres. Additionally, the new Pantera has a new chassis, integrating slope compensation as well as the ability to offset the track width from front to back, so the soil is travelled over just once. Although the Pantera’s tank volume has significantly increased, the extra kerb weight empty is only marginal, as well as maintaining the 50:50 weight distribution found in the Pantera 4504.

With the UX trailed sprayers, whatever the spray tank level, the tractor always has an optimal drawbar load, ensuring there’s traction without getting bogged down. Adding a front tank to the UF mounted sprayer brings higher capacity with improved weight distribution. These are available with capacities up to 3500 litres. The continuous mixing between the front and rear tank means the two tanks behave as one, with minimal operator input required.

Spray technology is rapidly changing with precise and accurate agrochemical application being key to maximising chemical efficacy whilst minimising costs, and for this we’ve introduced the DirectInject system for Amazone trailed and self-propelled sprayers. A 50-litre neat-chemical direct-feed system provides quick metering of additional plant protection agents on demand. This allows a quick response to changing field conditions where a specific agrochemical may be required to be added or removed from the chemical mix.

At the push of a button, or through variable rate maps, a neat chemical is injected and mixed into the secondary circuit, with a reaction time of 30m. The treatment area can thereby be limited to where a certain pest is present, or applied chemical can be reduced near watercourses. DirectInject is available on UX 01 Super range of trailed sprayers which now includes tank capacities from 4600 to 9000 litres as well as the tandem axle, 12000-litre capacity machine.

Amazone’s L3 boom has now been extended with the newly released 48m wide version, including newly developed SwingStopPlus as standard on all booms over 39m. SwingStopPlus is a further addition on the SwingStop technology which uses gyroscopic sensors on the boom tips to counteract and dampen any boom oscillation. SwingStopPlus can dampen both sides independently, resulting in the elimination of under and over spraying on boom tips as booms swing forwards and backwards, typically a considerable concern for larger boom widths.

Amazone’s ContourControl boom guidance system is now also supported on the UF mounted sprayers. The fully automatic hydraulic boom guidance system with side-independent positive and negative angling has been available on Amazone self-propelled and trailed sprayers for a number of years. Now passed on to the UF range, it allows allows the boom to follow highly uneven topography yet still maintain an optimal distance to the target surface across the full working width, even on extremely hilly terrain.

Across the trailed and self-propelled ranges, AmaSelect smart individual nozzle switching enables additional precision with curve compensation for even dose rates across the boom even while turning. CurveControl achieves this by calculating the boom speed at each individual nozzle and automatically changing the nozzles or nozzle combinations to maintain dose rate and droplet size. This significantly reduces under- and over-dosing, especially along headlands and in areas of tight cornering, such as around telegraph poles.

At the Cereals Event this summer, we will be demonstrating the attributes of the AmaSelect system with row spraying, spot spraying and CurveControl.