Written by Noah Newman and published by No-Till Farmer, 30 January 2024

Clay Mitchell, no-tiller and co-founder of farmland venture capital firm Fall Line Capital, delivered a presentation at the 2024 National No-Tillage Conference on what no-tillers stand to gain from working with ag startups and new technologies.

During the presentation, Clay questioned how to identify the best investments for your no-till operation.

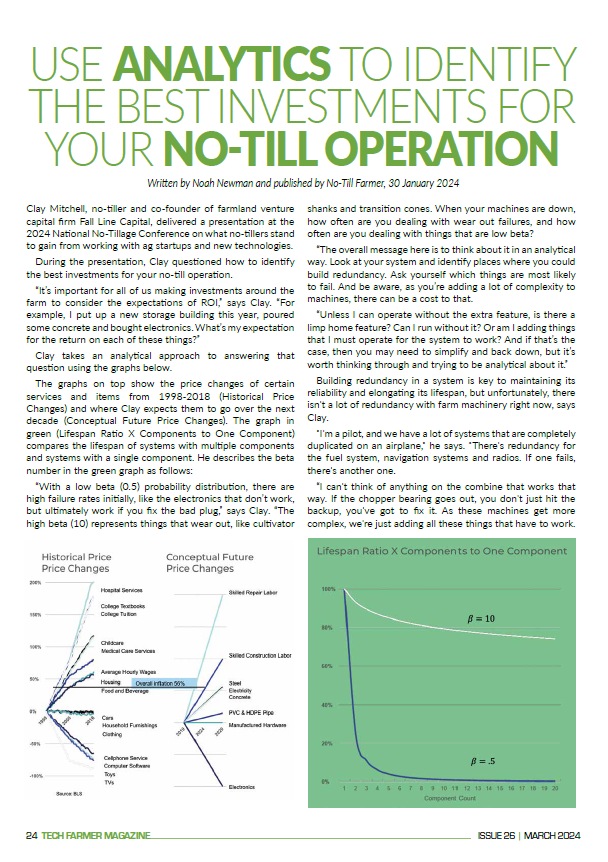

“It’s important for all of us making investments around the farm to consider the expectations of ROI,” says Clay. “For example, I put up a new storage building this year, poured some concrete and bought electronics. What’s my expectation for the return on each of these things?”

Clay takes an analytical approach to answering that question using the graphs below.

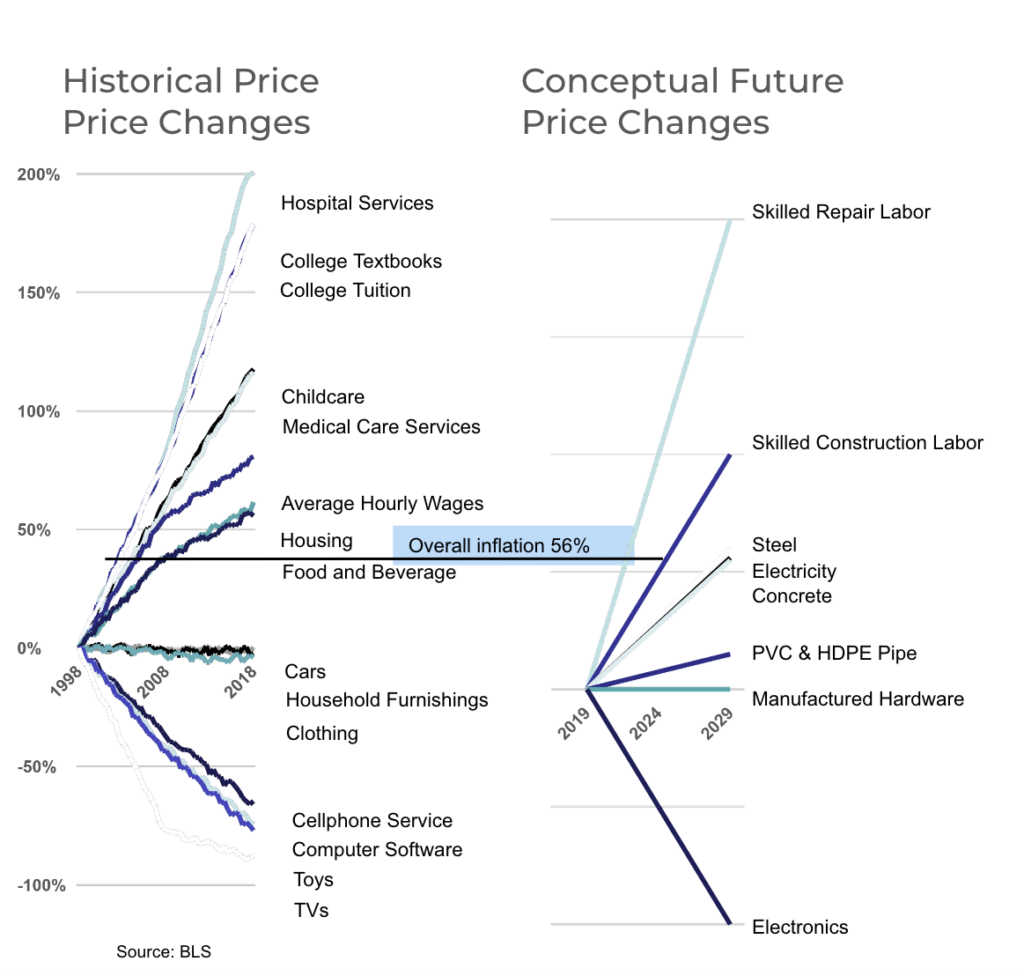

The graphs on top show the price changes of certain services and items from 1998-2018 (Historical Price Changes) and where Clay expects them to go over the next decade (Conceptual Future Price Changes). The graph in green (Lifespan Ratio X Components to One Component) compares the lifespan of systems with multiple components and systems with a single component. He describes the beta number in the green graph as follows:

“With a low beta (0.5) probability distribution, there are high failure rates initially, like the electronics that don’t work, but ultimately work if you fix the bad plug,” says Clay. “The high beta (10) represents things that wear out, like cultivator shanks and transition cones. When your machines are down, how often are you dealing with wear out failures, and how often are you dealing with things that are low beta?

“The overall message here is to think about it in an analytical way. Look at your system and identify places where you could build redundancy. Ask yourself which things are most likely to fail. And be aware, as you’re adding a lot of complexity to machines, there can be a cost to that.

“Unless I can operate without the extra feature, is there a limp home feature? Can I run without it? Or am I adding things that I must operate for the system to work? And if that’s the case, then you may need to simplify and back down, but it’s worth thinking through and trying to be analytical about it.”

Building redundancy in a system is key to maintaining its reliability and elongating its lifespan, but unfortunately, there isn’t a lot of redundancy with farm machinery right now, says Clay.

“I’m a pilot, and we have a lot of systems that are completely duplicated on an airplane,” he says. “There’s redundancy for the fuel system, navigation systems and radios. If one fails, there’s another one.

“I can’t think of anything on the combine that works that way. If the chopper bearing goes out, you don’t just hit the backup, you’ve got to fix it. As these machines get more complex, we’re just adding all these things that have to work. Airplanes are complex, too, but there are extreme efforts that are put into maintenance, repair and engineering that comes with a high cost to make sure everything is reliable.”

Looking at the graphs above, the inflation rate for hospital services, college textbooks and tuition have gone way up, whereas TVs, toys and computer software have plummeted. What does this information mean for your operation?

“I imagine that skilled labour is going to go way up in cost,” says Clay. “The complicated stuff that’s breaking down a lot is going to cost more and more to fix. Electronics are going to come down.

“For the things I expect to go up, there’s also more of a willingness to pay for them to make sure you’re building them in a reliable way that makes them last for a while. For example, the PVC and steel for our irrigation systems have doubled or tripled in price since we’ve installed them. It’s made for a better investment, and it was good that I put a lot of effort into making them reliable,” he concludes.