Precision application techniques enable farmers to deliver products more effectively and with greater accuracy onto intended targets, says James Thomas, Syngenta Head of Precision Agriculture EU+.

Rapid adoption of precision application techniques gives the potential to get a better result from every gramme of active ingredient in the field, and reduce the risk of any active finding its way out of the field and into the environment. Both those objectives make absolute sense, for the farmer to achieve a better result in economic yield and crop quality, and for wider ecological protection.

Across the EU there has been a stated position to see a 50% reduction in pesticide use by 2030. While the UK is no longer bound to abide by the EU legislative framework, there will inevitably be some consensus in common standards and conditions. Although recent reports of farmers’ direct action in the EU has seen some publicised watering down of political proposals and omissions of immediate pesticide targets, in reality those pressures are not going to go away.

There is a wider societal desire for reduced reliance on pesticide use. Growers can respond by looking at ways to implement changes as quickly and effectively as possible that will demonstrate continued capability for productive agriculture, within the constraints of the tools available.

Environmental protection is higher on the agenda and more rigorously policed than ever. More sensitive testing can now detect residues in food and the wider environment at infinitesimally small levels. While the science may say that level of exposure is of no consequence, inevitably the drive will be to see zero tolerance of detection.

Precision application techniques have the potential to help growers to meet the primary challenges of regulatory measures, including reducing spray drift and its impact on off target crops or features, such as water courses and environmental areas; mitigating the risk of point source contamination during the filling and operation of sprayers; preventing exposure of operators during application and cutting potential for residues in food products to a minimum.

Adopting precision application technology will also enable growers to radically change their approach to crop agronomy. Historically the approach to any weed, pest or disease issues has primarily been a broad-brush blanket approach to treating the whole field the same. Now, a combination of advanced monitoring and detection, with precision application techniques can enable targeted application only when and where the challenge presents. That offers huge potential to reduce the overall level of product use – thus meeting legislative obligations for reductions, along with lowering production costs and improving efficiency.

It also opens the exciting potential for new products designed specially for targeted application that could never be economically viable on a broad-acre field application basis.

The potential for precision application is two-fold – to protect the chemistry that we have for longer within the regulatory framework, and to potentially enable more new products to be developed.

Increasingly new actives are being introduced with either a reduced number of applications or lower rates of application permitted. With only one or two applications, it becomes even more important to target treatment more effectively. Precision application techniques have shown the potential to deliver the same, or better, results, from significantly reduced active ingredient use.

The future also holds the introduction of more biological products, for use in their own right or as integrated strategies with conventional pesticides. Precision application also has an essential role in the development of biological products. With the extensive trials and Syngenta R&D investment with biological products, it is understood that the results require more nuance and as a result the outcomes can be less consistent than with traditional CP products. This further emphasises the importance of accurate and timely applications.

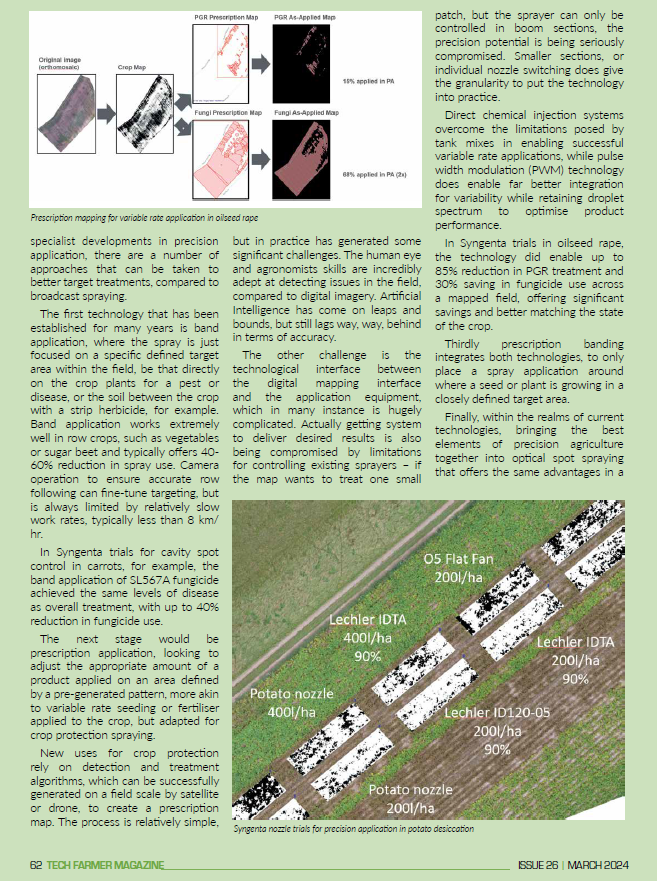

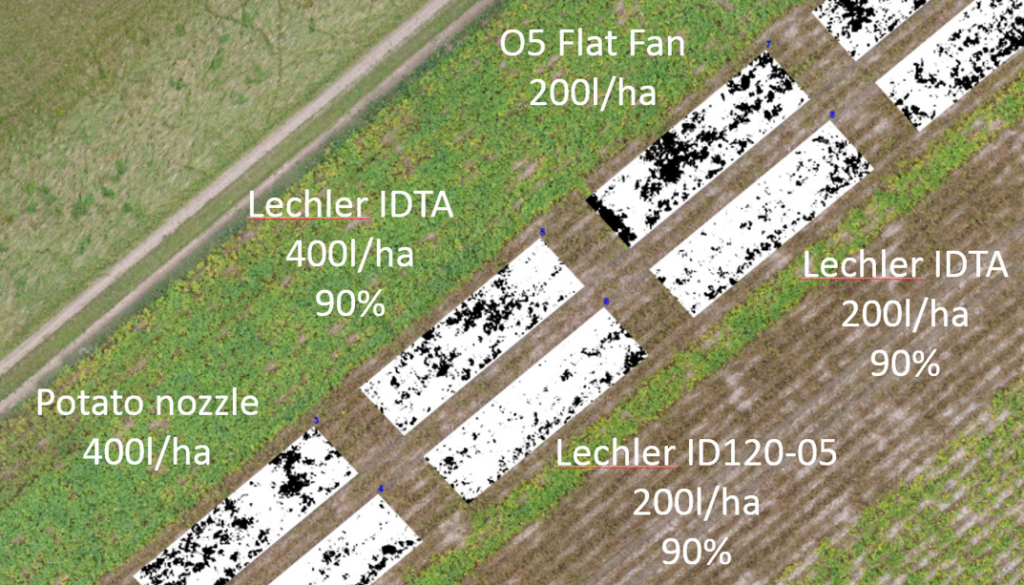

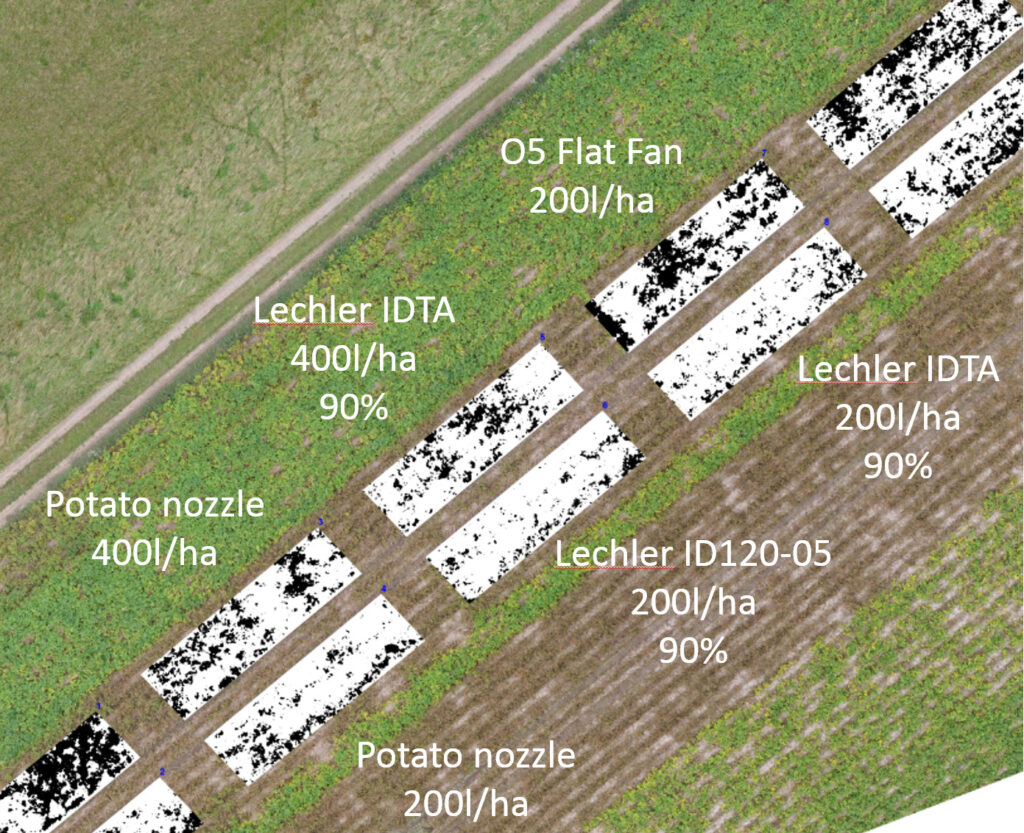

The first step to precision application, which doesn’t require any great investment or new technologies, is getting the basics right with the farm equipment currently being used and integrating optimum ways to deliver products, including nozzle selection; water volumes; adjuvant formulation technology and sprayer set-up.

Within Syngenta, the R&D investment is looking at precision application technologies that will meet objectives for growers to improve productivity, while also fulfilling regulatory objectives. The primary focus areas within that include weed control, including grass weeds in cereals and clean seedbeds; insect pests in high value vegetable and fruit crops where losses can be catastrophic and disease control including open field crops.

When we start to look at more specialist developments in precision application, there are a number of approaches that can be taken to better target treatments, compared to broadcast spraying.

The first technology that has been established for many years is band application, where the spray is just focused on a specific defined target area within the field, be that directly on the crop plants for a pest or disease, or the soil between the crop with a strip herbicide, for example. Band application works extremely well in row crops, such as vegetables or sugar beet and typically offers 40-60% reduction in spray use. Camera operation to ensure accurate row following can fine-tune targeting, but is always limited by relatively slow work rates, typically less than 8 km/hr.

In Syngenta trials for cavity spot control in carrots, for example, the band application of SL567A fungicide achieved the same levels of disease as overall treatment, with up to 40% reduction in fungicide use.

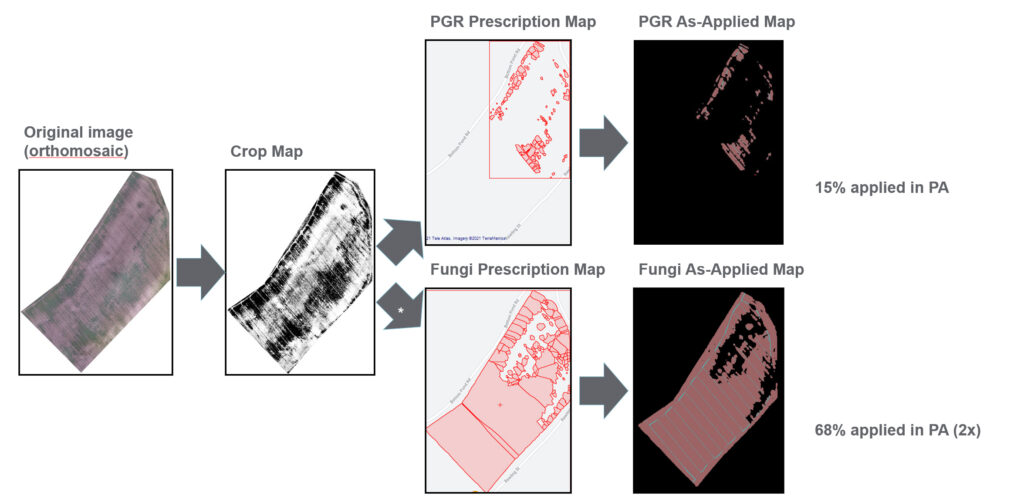

The next stage would be prescription application, looking to adjust the appropriate amount of a product applied on an area defined by a pre-generated pattern, more akin to variable rate seeding or fertiliser applied to the crop, but adapted for crop protection spraying.

New uses for crop protection rely on detection and treatment algorithms, which can be successfully generated on a field scale by satellite or drone, to create a prescription map. The process is relatively simple, but in practice has generated some significant challenges. The human eye and agronomists skills are incredibly adept at detecting issues in the field, compared to digital imagery. Artificial Intelligence has come on leaps and bounds, but still lags way, way, behind in terms of accuracy.

The other challenge is the technological interface between the digital mapping interface and the application equipment, which in many instance is hugely complicated. Actually getting system to deliver desired results is also being compromised by limitations for controlling existing sprayers – if the map wants to treat one small patch, but the sprayer can only be controlled in boom sections, the precision potential is being seriously compromised. Smaller sections, or individual nozzle switching does give the granularity to put the technology into practice.

Direct chemical injection systems overcome the limitations posed by tank mixes in enabling successful variable rate applications, while pulse width modulation (PWM) technology does enable far better integration for variability while retaining droplet spectrum to optimise product performance.

In Syngenta trials in oilseed rape, the technology did enable up to 85% reduction in PGR treatment and 30% saving in fungicide use across a mapped field, offering significant savings and better matching the state of the crop.

Thirdly prescription banding integrates both technologies, to only place a spray application around where a seed or plant is growing in a closely defined target area.

Finally, within the realms of current technologies, bringing the best elements of precision agriculture together into optical spot spraying that offers the same advantages in a completely dynamic and autonomous decision-making system operating in real time.

The principle of using sensors mounted on the sprayer to detect targets in the crop, and transform that information to switch on or off the nozzles, can give ultimate control. There are already a number of businesses starting to utilise the technology and, for some crops and some targets, it is working well to deliver savings in excess of 80%.

The challenge, as with prescription mapped systems, is with generating the algorithms to reliably drive the technology. Where there is clear differentiation between the target and the non-target, such as clumps of grass weeds in a stubble – or green on brown – for example, it can deliver excellent reliability at high speeds and efficiency, particularly in areas with low or patchy weed populations.

In Syngenta trials for green-on-green optical spot spraying, however, while the sprayer technology and nozzle switching has undoubtedly shown promise to target specific weeds and reduce overall product used, the software and algorithms have yet to prove sufficiently reliable and consistent in field operation.

The concept of being able to better target specific weeds in grassland, for example, has enabled the control of yield robbing docks, thistles and nettles, while leaving desirable clovers and herb-rich pastures. At the same time up to 60% reduction in product use during standard field-scale sprayer operation offers significant savings and compliance with dairy farmers’ customer demands for more sustainable farming practices.

There is a lot of talk about drone application in the sphere of precision application. It does have certain benefits and potential uses, including removing risks to operators in complex situations and giving access to difficult or dangerous positions. In specialist agriculture and amenity sector the technology may offer significant advantages and attractions. The technology will be able to make use of optical spot spraying innovation as it develops, but with the need for miniaturisation down to on-board drone scale. However, for broadacre crop, and certainly within the current legislative framework, drones are unlikely to feature without significant future investment.

Precision application developments continue to move at a fast pace. Each iteration is more reliable and offers greater advantages. The challenge for growers is often at what point to adopt the technology and which options to invest in that will be future proofed for the farm business.

But the direction of travel towards more precise techniques that allow better target application is essential for the efficiency of farm production. And with better targeting comes the chance to meet regulatory objectives, that will assure future product availability.