WHAT WILL THE NEW SEASON HOLD IN STORE?

As part of his ongoing series chronicling events on E. T. Claydon & Sons’ farm in West Suffolk, Jeff Claydon, who invented the Opti-Till® System of direct strip seeding, reflects on last season’s challenges and outcomes, together with how he is approaching the season ahead. The article was written in mid-August.

Most farmers in the UK will be glad to see the back of the 2019/20 season, which was fraught with challenges caused by a triple weather-whammy. Winter was the wettest since national records began in 1910 and on the Claydon farm we recorded only three rain-free days from October through to mid-March. The exceptionally dry spring which followed was, according to the Met Office, the sunniest on record and exceeded the previous UK-high of 555 hours in 1948 by 71 hours. Summer was one of the driest on record.

With all that going on there was never any chance of matching five-year yield averages, much less of breaking records and the Claydon farm was no different.

The difficulties of operating during the COVID-19 lockdown only added to the challenges of farming in an annus horribillis, to use the words of Queen Elizabeth II. Not being a Latin scholar, at times I resorted to more Anglo-Saxon terminology!

Rather than dwelling on problems, I like to take a positive view. When government restrictions prevented Claydon Drills from welcoming the hundreds of existing and potential customers who normally attend our open days in May we filmed a virtual event to highlight the progress of our crops and soils. That was a great success, and you can still view it on the website (claydondrill.com/news/article/virtualopen-day-overview)

Ironically, May was the sunniest in the UK since 1929 and the driest in England with 9.6mm of rain, 17% of the long-term average for that month. On the Claydon farm we had even less. Just 4.2mm of rain fell in May, so the 35.8mm in June really did save the day, but the 48mm in July arrived too late to contribute to yields.

Last season, despite the very wet autumn, all 280ha of winter wheat, beans and oilseed rape went in as planned. The winter wheat was established by 31 October, the last winter beans went in on 19 November and the remaining 46ha of spring crops were drilled directly into a perfect growing environment at the end of March.

The beans desperately needed more rain in May to produce stem and pod growth. The lack of it meant that the crop never grew more than 45cm high but produced a plethora of pods, many of them extremely close to the ground. Fortunately, almost two decades of direct strip seeding using the Opti-Till® System has left our fields very well structured, supportive and almost perfectly level. That was a huge benefit because it allowed the 12m header on our Claas Lexion 600 Terra-Trac to shave the beans off at ground level and recover most of the pods. The task would have been impossible on farms where deep ruts were created by spraying and spreading machinery during the very wet winter, and significant potential yield would have been lost.

The lack of moisture also took its toll on the oilseed rape, which reached a maximum height of 70cm, but it podded well and harvested easily during the last few days of July. All things considered, it turned in a reasonable yield, albeit slightly below our long-term average. Harvest was incredibly early this year, a couple of weeks ahead of where we would be normally, and the wheats fared best. Yields were slightly less than I would have liked but given the extreme lack of rain and very warm weather that was always to be expected. On the plus side, quality was excellent and exceptional hectolitre weights meant no deductions. After getting off to a flying start in April, our spring oats slowed due to the lack of moisture and were yet to be harvested at the time of writing.

All of us will be hoping for better things from the season ahead, but on a positive note, the exceptionally dry spring and summer created an immense amount of soil fissuring on our heavy land which partially offset the negative effects of the extremely wet winter on soil condition.

Hoping for a better season

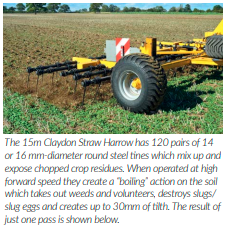

After harvesting oilseed rape during the last week of July we immediately got to work with our 15m Claydon Straw Harrow to kick-start the process of germinating volunteers and weed seeds. This is a key part of the stubble management process and critical to growing clean, high-quality, high-yielding crops.

Exceptionally hot weather during midAugust made us cautious about using this very useful implement on fields situated close to local houses as working the bonedry soils would have created a lot of dust and probably upset our neighbours. After a spell of heavy rain the Straw Harrow easily produced 20mm of tilth and a carpet of green growth emerged a few days later, so we carried out a second pass to thin the self-set oilseed rape and allow any grassweeds to be sprayed out. The volunteer oilseed rape which remains will act as an improvised cover crop, so it will be interesting to see if this will further benefit soil condition and health, which are already excellent. We will stop using the Straw Harrow three weeks before drilling and spray off any remaining material with Roundup® shortly before winter wheat is sown in early October. It will be interesting to see if this improvised cover crop will further benefit soil condition and health, which are already excellent.

Weather permitting, we will carry out another two or three passes with the Straw Harrow across the other stubbles during the next few weeks to take out as many slugs, slug eggs and volunteers as possible before drilling autumn sown crops. This season we will have just over 200ha of winter wheat, all feed varieties as there are several good homes for those locally. The balance of our 326ha will be 46ha of oilseed rape, 25ha of winter beans and 55ha of spring oats.

Oilseed rape went into wheat stubbles on 8 and 9 August, somewhat earlier than normal because last season we found that drilling on 10 August compared with 10 days later produced an additional 0.25t/ ha. After drilling the oilseed rape, we had five consecutive days of 30°C-plus temperatures which peaked at 36°C and had me worried, but after 25mm of rain the following week the crop got off to a flying start. It looks good, as does the oilseed rape which we drilled for a contract customer who was so pleased with the 150ha that we established for him last year with our 6m Claydon Hybrid because it yielded 4.5t/ha that he asked us to do more this season.

Will cover crops be of benefit?

This season we are experimenting with a cover crop on some of the 55ha destined for spring oats and have drilled Hutchinsons MaxiCover, a generalpurpose over-winter mix containing linseed, buckwheat, phacelia, daikon radish, fodder radish, brown mustard, hairy vetch and crimson clover. It will be interesting to see if it has a positive effect in terms of controlling grassweeds and further improving soil condition.

We drilled it at 12.5kg/ha on 9 August using three approaches. In one area we used the standard Claydon Opti-Till® set-up, comprising a patented leading tine which relieves compaction and aerates the soil followed by a seeding tine fitted with a 20cm A-share. In another area we used the leading tine followed by our new lower-disturbance ‘LD’ twin-tine kit and finally the twintine kit preceded by double front cutting discs which reduce power requirement by up to 50% and minimise soil disturbance.

Changing from the standard seeding tine to the twin tine is as simple as undoing three bolts and takes minutes. With a few simple, quick modifications any new or existing Hybrid drill can now be used for conventional sowing, lower disturbance establishment and zerotill seeding, with or without fertiliser placement between or in the seeded rows, directly into stubbles, chopped straw, cover crops and grassland. This makes them a much more versatile and cost-effective solution compared with purchasing a strip till drill and specialist low-disturbance drill. The two 44mm x 12mm hardened steel tines in the twin-tine unit are four times stronger than normal 30mm x 10mm tines. Fitted with 15mm points, they incorporate unique double-leaf helper springs which maintain a consistent seeding depth even in very dry, hard, heavy soil conditions, yet permit enough lateral movement to displace surface trash and prevent blockages.

This approach provides a more traditional finish than band seeding and the seeded rows from the twin tine setup are normally spaced 150mm apart. The brackets which hold the tines in place can be moved in by 50mm and this allows the width of the seeded band to be reduced to 100mm, providing more space for a Claydon TerraBlade inter-row hoe to take out weeds growing between the rows. This can be done in the autumn once the crops are sufficiently well established, right through until late spring before the TerraBlade would damage the growing crop. The TerraBlade is an excellent mechanical method of enhancing chemical control.

For ultra-low-disturbance drilling of soils in excellent condition the Hybrid drill’s standard leading tines can be replaced with twin 330mm-diameter front cutting discs. These can be either the plain design or new fluted ‘Spiradisk’ which does an excellent job of cutting through trash without ‘hairpinning’ material into the slot and creates a slightly wider channel and just the right amount of tilth to provide perfect growing conditions.

It will be interesting to see how these establishment methods compare, so I will go into more detail about them and our cover crop trials in the winter issue of Direct Driller magazine. In the meantime, you can find out more about the Claydon Opti-Till® System by contacting your local Claydon dealer, calling the Claydon office on 01440 820327 or visiting the website: claydondrill.com. Videos of the new LD options in action can be viewed at claydondrill.com/lower-disturbance.