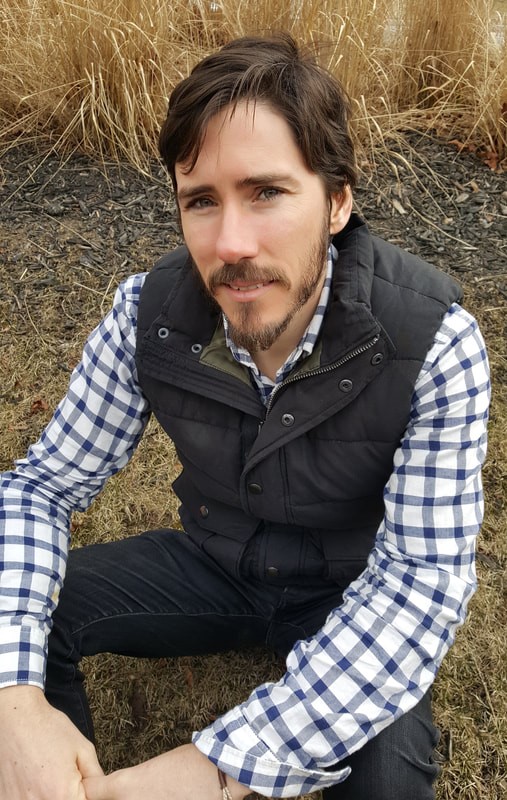

As more growers use foliar nitrogen applications, Direct Driller picks out some practical tips about how to formulate mixtures for maximum efficacy from Joel Williams’ masterclass.

Written by MIke Abram

Foliar feeding potentially offers a more efficient and quicker route to get nitrogen into a crop, particularly later in the season, but it does come with some risk, such as scorching leaves and from inconsistent results.

Minimising those risks comes from paying close attention to formulating applications correctly, suggests Integrated Soils’ Joel Williams. Earlier this spring he put together a lecture series providing detailed information and advice about how to maximise foliar nitrogen applications.

Most foliar nitrogen applications are based on urea, which has a number of advantages, he says.

First, urea is much quicker to be absorbed into plants because of its neutral charge than ammonium or nitrate. That’s important to optimise the plant’s health and nutrient status compared with soil applications, which are generally slower to move into the plant.

“We can get foliars into the plant much quicker than soil-based applications,” Mr Williams says.

Amino acids are generally even quicker to get into a plant, but urea is attractive because of a lower cost / unit of nitrogen than amino acids.

“There’s also an interesting review that suggests urea is a good chelator – when you mix it with other nutrients it improves the uptake of those nutrients, especially trace elements, such as zinc and iron.”

If making your own foliar urea on farm by dissolving granular urea in water, remember this is an endothermic reaction – in other words in the process of dissolving pulls in heat dropping the temperature of the water significantly.

“As the temperature drops, it becomes harder to then solubilise the rest of the urea, so any strategies you can use to increase water temperature will be help.”

That’s probably not going to extend to paying energy costs to warm water, Mr Williams says, but if you’re using any kind of below ground water source, pumping it to the surface can help warm it. Likewise, storing water in a black tank in the sun for a couple of days before use will also help warm it up by a few degrees.

“That can make all the difference,” he says.

The other key thing when solubilising urea is keeping the water circulating, especially at the bottom of the tank, while feeding the urea in slowly. “I know some farmers are putting all the urea in at the same time and making it work, but slowly feeding it in minimises the risk of clumping and settling at the bottom of the tank.”

Optimising foliar urea applications is much more than just spraying dissolved urea, however, he stresses. He recommends a number of other additions to the tank.

“On top of foliar nitrogen, it’s also about all the other nutrients that work with nitrogen, particularly the trace nutrients and some of the macronutrients, like sulphur, potassium and magnesium that work with nitrogen to support its movement through the metabolic pathway and its role in growth and protein development.

“So in a nitrogen strategy, we have to think about the other nutrients.”

Nickel, for example, is critical for urease to break down urea, while molybdenum, sulphur and iron are important for the nitrite and nitrate reductase enzymes to break down nitrate into ammonium. Manganese and magnesium are crucial for amino acid production, while a whole range of minerals play a role in converting amino acids into proteins.

If there is a deficiency of any of these key minerals it potentially can cause a backlog of nitrate or ammonium to build up with consequences for plant health, Mr Williams explains.

A plant sap or tissue analysis can help determine whether these or other nutrients are required, he says.

Mixing the nutrients with a carbon source helps bind the nutrients. Carbon acts as a sponge for positively charged nutrients, enhancing uptake and improving the permeability of the plant cells.

“They will be less reactive, less likely to lock up with other nutrients in the tank, and in the case of urea, less likely to volatilise off the leaf surface.”

Humic and fulvic acid are the most common organic chelators. For foliar applications, Mr Williams prefers fulvic acid as it is a smaller molecule that will pass into the leaf more quickly.

Another reason is humic acid is only soluble under alkaline conditions, which with a target spray pH of 5 or 5.5 there is a risk of it jellifying in the tank, while fulvic acid remains in solution at all pHs.

Other potential carbon sources include molasses and do-it-yourself sources of amino acids, such as fish or other protein hydrolysates. Molasses is less effective at chelating nutrients, but has other beneficial properties, he says.

Studies have shown that applying molasses stimulates microbes to digest nutrients, converting them into a stabilised form in their bodies, which are then recycled over a slower time frame.

Amino acids, on the other hand, are a very efficient form of getting nitrogen into plants, as they are further along the pathway to being converted into proteins.

“It’s sometimes beneficial to use a diversity of carbon sources with different modes of action and roles,” Mr Williams suggests.

Other useful additives in the spray tank include wetters, stickers or spreaders that can beneficially modify the behaviour, activity or availability of the nutrients.

Water conditioners, such as ammonium sulphate or citric acid that help make sure the spray solution hits the target acidic pH for optimal absorption of nutrients should also be added where required, Mr Williams adds.

With multiple additives and nutrients in the tank, do a jar test to check compatibility, he advises. Soluble forms of calcium can be problematic, for example, especially with sulphur and phosphate as it can precipitate out, he concludes.

What causes scorch?

Scorching of leaves is a common problem with foliar urea applications, and the primary cause is either an excess of urea or ammonium in the leaf, Mr Williams says.

If the pathway which converts urea into ammonium or ammonium into amino acids is blocked that can lead to a build-up urea or ammonium in the leaf causing toxicity, he explains.

There can be various reasons behind this, from a lack of key nutrients to build the enzymes to convert urea or ammonium, over-applying of urea or ammonium, or environmental conditions slowing the enzyme activity.

Biuret, a contaminant in urea manufacture, can also contribute to scorch, albeit more in perennial crops where it can build up over time than annual crops, Mr Williams notes. “If it is 1% or less then it is a good source for foliar spraying.”

Additions of nickel, manganese and / or magnesium sulphate can help facilitate the conversion of urea to avoid scorch, as can applying foliar sprays in high humidity, and avoiding spraying on bright sunny days, in windy conditions or in low temperatures.

“Whenever we have a low metabolic rate in the plant, whether it is from environmental stress such as low temperatures, drought stress or herbicide injury, that is when urea or ammonium can build up and cause potential toxicity.”

[Box] 5 building blocks in a foliar urea application

- Nitrogen source(s)

- Urea @ 10-20 kg/ha

- UAS/UAN @10-20 L/ha

- Ammonium sulphate 5-7 kg/ha

- Use tissue / sap analysis

- To determine optimum combinations of synergistic nutrients to go with nitrogen

- Carbon source(s)

- Fulvic acid @ 1-2 L/ha

- Fish hydrolysate @ 2-5 L/ha

- pH adjustment

- Citric acid to pH 5-5.5

- Wetter / sticker / spreader