Bourgault Tillage Tools UK have been working hard Over the winter months to develop a replaceable coulter tip tine option for a number of the most popular seed drills that are currently in the marketplace. The objective is to give greater versatility to the farmer whilst saving money in wasted metal and delivering great seed placement with minimal disturbance.

The replaceable coulter tip tine option is available for the following

- Weaving Sabre Tine

- Amozone Cayenna

- Kuhn Migant

- Most self builds with rigid tines.

The popularity of these seed drills has increased dramatically over the past few years. With the available grants and the seasonal variable weather patterns many farmers are turning to this design of seed drill where others fail. Some farmers are using these drills as their only seeding option, however many larger growers and contractors are using them as back up when larger disc drills cannot operate. With the self-build options, a neat self-weld on socket can be used to turn any vertical rigid tine into a replaceable coulter tip tine.

Weld on nose socket gives access to a wide range of replaceable coulter tips.

UK Trials

The initial thoughts about achieving a replaceable coulter tip tine was at groundswell 2022 whilst talking to farmers and listening to what their concerns where about these machines. Work started almost immediately in the design process. We knew that we already had a magnificent range of tips available to us from the BTT foundry in Saskatchewan Canada. All of these tips, their design and there manufacture is well proven and nothing knew with millions of hectares of ground seeded globally with these products. The difficult bit was for Stuart Aldworth (Technical Manager BTT UK) And the design team to come up with a way off designing the replaceable tip tine whilst not detracting from the original manufacturers whole good design’s and functionality. Primarily all that Bourgault Tillage Tools are interested in is the bottom 3 inches of any tine. Within two months a few replaceable tip tines were made and initial trials could take place to prove the concept.

Through our farming contacts we were aware of a weaving Sabre tine that is owned and operated by farmers and contractors James and Chris Mizen from Love’s Farm, Cutlers Green, Essex. We were also very aware that the ground that the Mizens farm was very heavy Essex clay which has extremely high wearing properties. The perfect place for a trial for the new replaceable coulter tip tine.

First Trial Coulter Tip Tine, VOS 19mm Tip with fixed seed tube like the Amazone Cayenna.

The BTT trial coulter tip and tine were put on alongside new Weaving OEM tines and did a total of 800 acres of drilling during the autumn and spring at Loves Farm, Essex

Initial on farm photos for both the Weaving OEM Tine and the BTT Replaceable coulter tine and VOS 19mm tip

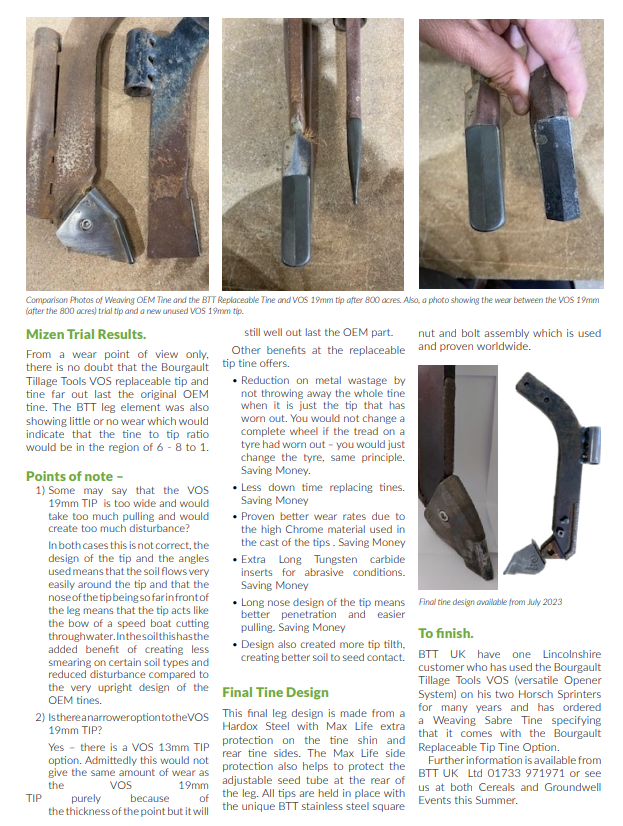

Comparison Photos of Weaving OEM Tine and the BTT Replaceable Tine and VOS 19mm tip after 800 acres. Also, a photo showing the wear between the VOS 19mm (after the 800 acres) trial tip and a new unused VOS 19mm tip.

Mizen Trial Results

From a wear point of view only, there is no doubt that the Bourgault Tillage Tools VOS replaceable tip and tine far out last the original OEM tine. The BTT leg element was also showing little or no wear which would indicate that the tine to tip ratio would be in the region of 6 – 8 to 1.

Points of note –

- Some may say that the VOS 19mm TIP is too wide and would take too much pulling and would create too much disturbance?

In both cases this is not correct, the design of the tip and the angles used means that the soil flows very easily around the tip and that the nose of the tip being so far in front of the leg means that the tip acts like the bow of a speed boat cutting through water. In the soil this has the added benefit of creating less smearing on certain soil types and reduced disturbance compared to the very upright design of the OEM tines.

- Is there a narrower option to the VOS 19mm TIP?

Yes – there is a VOS 13mm TIP option. Admittedly this would not give the same amount of wear as the VOS 19mm TIP purely because of the thickness of the point but it will still well out last the OEM part.

Other benefits at the replaceable tip tine offers.

- Reduction on metal wastage by not throwing away the whole tine when it is just the tip that has worn out. You would not change a complete wheel if the tread on a tyre had worn out – you would just change the tyre, same principle. Saving Money.

- Less down time replacing tines. Saving Money

- Proven better wear rates due to the high Chrome material used in the cast of the tips . Saving Money

- Extra Long Tungsten carbide inserts for abrasive conditions. Saving Money

- Long nose design of the tip means better penetration and easier pulling. Saving Money

- Design also created more tip tilth, creating better soil to seed contact.

Final Tine Design

Final tine design available from July 2023

This final leg design is made from a Hardox Steel with Max Life extra protection on the tine shin and rear tine sides. The Max Life side protection also helps to protect the adjustable seed tube at the rear of the leg. All tips are held in place with the unique BTT stainless steel square nut and bolt assembly which is used and proven worldwide.

To finish.

BTT UK have one Lincolnshire customer who has used the Bourgault Tillage Tools VOS (versatile Opener System) on his two Horsch Sprinters for many years and has ordered a Weaving Sabre Tine specifying that it comes with the Bourgault Replaceable Tip Tine Option.

Further information is available from BTT UK Ltd 01733 971971 or see us at both Cereals and Groundwell Events this Summer.