NEW TO THE UK MARKET IMPORTED BY SAMAGRI LTD

Who are Virkar?

Virkar was set up in 2010 by three young entrepreneurs: an engineer, a mechanic and a farmer. We were looking for a no-tillage machine that was superior to the most prestigious machines on the market. Capable of offering high yield that no other machine can match right now, and able to meet the highest expectations and requirements in the sowing process. Virkar wishes to listen to farmers and at the same time provide a modern and technological outlook, thanks to its multidisciplinary team, to create high quality and reliable machines whilst keeping them easy to handle with a high degree of innovation.

The Dynamic drill

The Virkar Dynamic drill is available in 4.5/5/6 meter working widths with bigger sizes in development for the future.

The drill is semi mounted and has a hopper capacity of 5300lts. The drill comes on flotation tyres 550/45 22.5 which ensures compaction in field is kept to a minimum.

Sowing rate from 2 to 380 kg/ha is achievable from one feed roller.

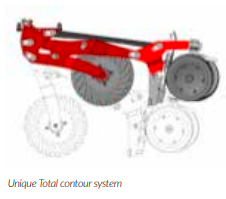

Total contour system

The modular coulter design consists of a turbo cutting disc, which is on a hydraulically pressured arm which ensures the turbo disc can cut a clean slot in the soil and create a micro tilth in front of the following seeding tine. Working independently from the turbo disc is a low disturbance seeding tine that not only places the seed at a very even depth, but because of its design the seeding tine cleans the slot of any trash leaving only clean soil in the slot, this means great seed to soil contact.

Following the seeding tine is a v shaped double press wheel which closes the slot. The drilling coulters are pressurised via a large accumulator all the coulters are linked together, this allows for very effective ground contour following with every coulter being able to travel up to 35 cm meaning even seed depth is achieved even in the most uneven terrain. Having the drill working off this accumulator means it is easy to change the pressure of the coulters, by a control box in the cab a dial is turned and from that more pressure is applied to the coulters which means even the hardest of ground is no problem to drill into.

Each coulter can apply 0/280kg of pressure to the ground. The seed depth is easily adjusted, the v shaped double press wheels are adjusted by a simple pull out pin the wheels can then be lifted, up or down and then the pin placed back meaning easy change of the depth.

Hopper

The seed hopper has the option of splitting the tank 65% seed 35% fertiliser running through 2 metering systems. In addition, liquid Fert can be specified as option. There is also the option of a third 600-litre seed-carrying element that can be dropped into the main hopper with a telehandler, where it is clamped in position. Free Drive the steering axle provides new freedom sowing on a curved path, the system frees up tension in the coulters arms meaning less stress is put on components leading to longer working life. Long life bushings for low maintenance, all sealed bearings on discs and press wheels so easy to maintain

Control System

Easy Vario controls in a simple way an advanced hydraulic system to lift lower and adjust coulter pressure from control box in the cab meaning adjustments can be made easily on the move without need to stop meaning a more productive working day. The drill comes ISOBUS ready and the seeding part can run through the tractors terminal and be set up to undertake variable rate seeding if necessary.

Modular Design

Another feature that stands-out is the flexibility to alter row width and full working width. Both the 4.5m and 6m versions use the same chassis, so owners can simply bolt extra frames onto the wings and fit the required number of coulter modules. You can shift the row widths from 19cm to 25cm (or vice versa) by moving the coulter units into the different predrilled slots on the frame.

Lastly if you’re thinking about sowing oilseed rape at 50cm centres, it’s a simple case of lifting the front row out of work.

Requirements

The Dynamic drill is very easy to pull because of its low disturbance meaning a 6 meter drill can be pulled by 180hp. The drill requires 4 spools if fitted with hydraulic drive for fan or 3 spools if drill is fitted with PTO pump to run the fan. It comes standard with LED work lights, tank lights, a decent size toolbox calibration bag and scales.

Summary

The Virkar drill offers users with a no till drill that is very flexible and can also work in min till systems just as well as it can in no till systems. The drill offers users with the flexibility of being able to drill in the toughest of conditions. Unique features such as the hydraulically powered cutting disc the steering rear axle and ease of operation makes the Virkar a seriously attractive drill for the modern farmer looking to invest in a machine that will serve them the same today as it will 10 years down the line.

For more information, scan the code below.