TALES FROM A BUSY SPRING

By James Dale

June will see Dale Drills showing at the Cereals and Groundswell shows, where we will be demonstrating our range of direct drills as well as showing our new low disturbance sub soiler; the Meir SC. This spring saw several new drill sales including our first machine in Norway. A 4m Eco-M was sent on a ferry from Immingham to Brevik then on to its new home in Kjeller, just North of Oslo. I was lucky enough to be sent to Norway to help the new owner set the drill up. Whilst there I realised this was the furthest North I had ever been, and yet the farming experience there seemed very similar to the UK.

Although the colder weather did highlight some different challenges, most of the 70cm of snow from Winter had melted by early April, but a milder winter had meant Snow Mold had been a major issue, with some fields of Wheat completely written off. Norway’s undulating terrain is another significant challenge, with plenty of arable fields on slopes of 20% or greater. Add to this the fact that most Norwegian Farmers consider a 150hp tractor to be huge, and you can begin to see why easy to pull drills are essential. Our customer used a John Deere 6125R tractor to pull the 4m drill. It managed it quite happily whilst I was there, and I was pleased to hear when my customer told me he had completed his spring drilling without struggling to pull the drill on even his steepest ground.

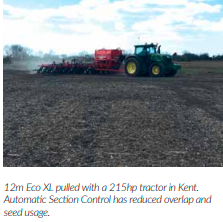

We also delivered a new 12m Eco-XL to a customer in Kent. The seed only drill was supplied with a pressurised tank split into 4 compartments. Each compartment supplies ¼ of the drill with seed via a metering unit driven by an electric motor. Using an Isobus connection to the customers John Deere 6215R tractor we were able to use a GPS controlled, automatic section control to dramatically reduce overlap and save on seed. After a trip through our workshop to have several modifications carried out, a used 3m Eco-M was also sent down to its new home in Kent. Our modular design allowed the drills working width to be increased to 5m via 2 x 1m hydraulically folding wings.

The seed and fertiliser option on the existing drill was bolstered with the addition of 2 new applicators; a Rotor Meter to feed product into the airstream to be drilled down the coulters and a Fan Jet Mini to spin product on behind the drill. Both applicators are controlled through the drills control screen, and automatically turn on/off with the drill as well as keeping rate consistent no matter what the forward speed. The drill was supplied with a deeper front tine kit allowing the owner to sow different seed types at different depths or to loosen to depth for ‘lazy’ rooting crops. Banded coulters allow the customer to spread seed in an approx. 100mm band whilst placing fertiliser 25mm deeper than the seed and in the middle of the band. A very versatile machine.

This spring also saw the launch of Dale Drills in France with our new French distributor. A 6m Eco-M made the journey to Beaumont Village, in the Loire Valley to carry out the first demonstration. Sorgo was planted into a cover of beans on some challenging soil with a high percentage of sandstone. The drill was configured with our cover crop cutting disc followed by a narrow duet tine allowing DAP fertiliser to be placed alongside the seed. Visitors were impressed with the versatility of the Eco drilling assembly and many commented on how well the tine was able to penetrate and how consistent the depth was across the width of the drill. Following its launch at the LAMMA show, the Meir SC has been put through its paces this spring with several developments made.

The cutting disc positioned in front of each subsoil tine has been increased in diameter from 350mm to 450mm. This provides a more effective cut through residue, whilst also reducing the amount of soil movement at the surface. The subsoiler point has been refined to include a 15mm wide, tungsten carbide protected point, reducing wear and soil disturbance. Behind the point, the low angled wings have received a coating of tungsten to boost endurance and ensure effective soil loosening throughout the life of the wing. The rear roller has been re-engineered to include a smaller diameter central tube with deeper corrugated rings positioned either side of each leg. This improves the finish left after the subsoiler, most notably behind the tines where the soil is ‘pinched’ back into place.

Available in 3m and 4m working widths, the Meir SC will be shown working this autumn. A Dale Drills 6m Eco-M will also be available on a short term hire this autumn for those interested in trying it on their farms.