CHANGING WEATHER PATTERNS AND EXTREME CONDITIONS HIGHLIGHT THE IMPORTANCE OF SOIL HEALTH

This season’s weather extremes highlight the importance of good soil health, says direct strip seeding pioneer and Suffolk farmer Jeff Claydon, who designed the Opti-Till® System.

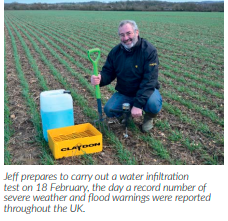

In the last issue I highlighted the importance of operating a crop establishment system which can cope with all conditions, the need to minimise weather risk and having machinery with sufficient capacity to exploit weather windows, allowing seed to be drilled at the right time and in the right conditions so that it produces high yielding, profitable crops. This time the focus is on soil health, a particularly relevant topic because as I write this on 18 February 2020 the extreme weather throughout the UK is headline news and a record number of flood warnings are in place. I sympathise with those who are affected and appreciate that, despite persistently wet conditions here in East Anglia, the region has got off lightly.

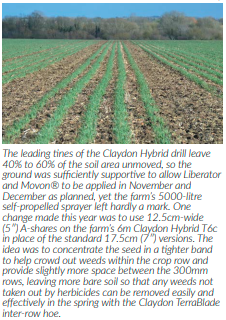

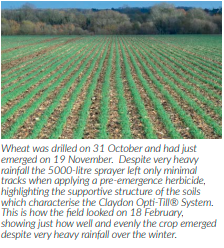

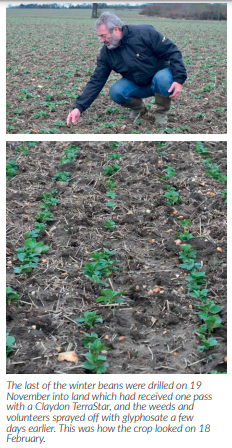

Crops never look their best in February, but I’m very pleased with those on the Claydon farm. After harvest we were able to carry out an effective stubble management programme using the 15m Straw Harrow and 6m TerraStar, get all our winter wheat in the ground by 31 October and completed the planned autumn establishment programme on 19 November when our 6m Hybrid T6c drilled the last of the winter beans. They established well and even the headlands look good. Checking the crops today reminded me that we would never have completed autumn drilling using a plough-based or min-till system; the plough-based taking four times as long and the mintill nearly twice the time.

When I walked our fields this morning the ground was so firm and supportive that my boots picked up very little mud – and this despite being a heavy clay farm. More remarkable was the fact that barely a mark, or any water, was visible in the tramlines where I had applied a pre-emergence herbicide to wheat in November and been through again in December with our 17-tonne, 5000-litre self-propelled sprayer.

After yet another night of heavy rain I did an infiltration test to check whether the soil could absorb any more water and whether any areas had drainage or compaction issues that may need to be remedied when conditions allow. The 20-litres of water in the infiltration tray is equivalent to 5″ of rain falling, but nevertheless it was absorbed fully in under five minutes, indicating that the soil is in excellent condition. I also checked for compaction, but even in the tramlines the indicator needle on the penetrometer never went beyond the green zone.

Travelling around the country on my way to visit customers I have seen countless examples of soils in poor condition, probably from being overworked, using inappropriate machinery, at the wrong time. Some fields were waterlogged, slumped and capped, worm activity was minimal, crops were stressed, and even weeds refused to grow in some areas. Elsewhere, vital topsoil which had taken millions of years to form had washed off fields into ditches, streams and rivers, causing pollution and crop loss.

In the 52 years that I have been involved on the Claydon farm I have tried every crop establishment system, under all conditions; it was their shortcomings that led me to develop OptiTill®. We’re now able to produce high yielding crops more efficiently, at much lower cost and with less agronomic and financial risk – all while improving our soil health. We have reduced our costs by £140/ ha – an excellent saving – but if our yields were to fall by 1t/ha, this saving would be wiped out. On the Claydon farm, we have never experienced any yield loss, just the opposite in fact. Independent tests by seed breeder Saaten-Union from 2006 to 2016 recorded an average 9% yield increase over a plough-based system, and up to 26% in an extremely dry year.

Soil Health is Critical

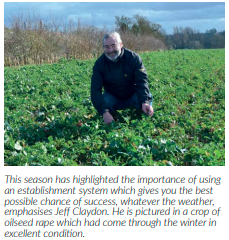

This season has been one the most challenging since 2012. It was too dry at the start and has been too wet ever since, although soil temperatures have averaged 1°C higher than last year. At a time when extremes of weather appear to be on the increase, good soil health has never been more important. Soil health comprises three elements:

• Physical health: Texture, soil structure, porosity/pore size distribution, water retention/ transmission and aeration

• Chemical health: Maintaining optimum pH, providing plant nutrients in the right amounts, in the right place, at the right time

• Biological health: Soil biodiversity, feed the soil regularly through plant and organic matter inputs, diversify plants in space and time

Dr Elizabeth Stockdale, Head of Farming Systems Research at NIAB, describes a healthy soil as one that can support crop and livestock productivity, whilst maintaining or enhancing environmental benefits, such as clean water, carbon sequestration and improved air quality. In healthy soils the interaction between soil chemistry (pH and nutrients), physics (soil structure and water balance) and biology (earthworms, microbes and plant roots) are optimised.

A well-structured topsoil has small, rounded, water-stable aggregates and a range of pore shapes and sizes that form a continuous network, allowing good aeration, root proliferation and better drainage. Plant roots and some organisms, such as earthworms, change the structure of the soil by moving through it, moving particles around and extracting water. Supporting the biological processes of structure formation and increasing soil matter content have been shown to help create resilient soil structures that can both absorb heavy rainfall and hold water in a drought.

A well-structured subsoil has vertically orientated, often continuous pores and fissures which are formed by physical shrink-swell processes and maintained by root and earthworm action. Between these pores the soil forms column-like structures, which in clay soils may be single prismatic aggregates. These give the overall soil profile strength to bear the weight of machinery. Such soils are resilient and better resist damage by compaction, but cultivations must be carried out with care to avoid weakening any natural column strength.

Recent data has shown that reducing the intensity of tillage operations benefits soil biology, with marked increases in larger invertebrate species, especially deep burrowing (anecic) earthworms, where inversion tillage is removed from the rotation. Examining soil physical structure should be done when it is in the moist to wet range, so early spring and late autumn are good times to get your spade out and have a systematic look.

How Opti-Till has worked this season

The OptiTill® System has been developed, refined and improved over 18 years, during which time numerous benefits have become apparent. They include huge time and fuel savings, much improved timeliness, faster emergence, larger and stronger rooting structures, improved soil health, greater resilience to extremes of weather and improved yields. Even headlands which we once accepted as not being particularly productive now yield just as well as the centre of the field.

A key reason is that the Claydon leading tine technology loosens soil only in the rooting and seeding zone, so the bands between the seeded rows (which make up 60-70% of the field area) are left intact. The leading tine aerates the soil, creating a friable tilth which provides the perfect environment for seedlings to germinate and develop strong, deep roots that tap into the moisture in the undisturbed areas. It also breaks up any shallow compaction and allows water to move away from the rooting zone, which eliminates ‘ponding’.

Because old rooting pathways remain in place the soil’s structure is not damaged, its density remains consistent and natural capillaries remain unbroken, allowing water infiltration and unimpeded rooting. This minimises stress on the crop throughout its life and means that soils managed using OptiTill® are much better able to support field traffic without the risk of compaction.

Earthworms thrive in unturned soil and their numbers have increased exponentially, vastly improving the soil to air ratio. The casts they leave on the surface are a tell-tale sign of good soil health and the channels they create, some over two metres deep, have been invaluable in draining water away from the surface this winter. Despite exceptional rainfall our soils have retained an excellent crumb structure and crumble between the fingers rather than clumping into a sticky, anaerobic mess.

The Hybrid drill has no press wheels touching moved soil so it runs when most other strip till, min till and nondisturbance drills can’t. A variety of options and adjustments are offered on the rear toolbars to suit different conditions to help get a fantastic finish. The Claydon drill can travel on firm stubble as opposed to the ‘porridge’ that is left in min-till systems when the moved soil gets wet and then can’t be worked until it dries out. Claydon Opti-Till® saves so much time it presents farmers with a wider window to get seed in the ground when the weather is good rather than having to cultivate it and then go out with a drill.

This is a huge benefit, for example, when drilling wheat behind maize late in the season. This is also a significant benefit for countries such as Scotland and the west coast of Denmark where harvests are late, and winters are early and cold, so farmers have a very short period to get crops in the ground and established. Particularly when drilling late after maize, the compaction created from post-harvest traffic with machinery including foragers, tractors and trailers is also alleviated by the Claydon leading tine.

The Claydon mounted Hybrid drill has been particularly effective this year at getting crop in the ground; comparatively, it doesn’t carry a lot of weight on the tractor, it has huge clearance and the leading tine has done its job at removing compaction, aiding drainage and creating tilth. Opti-Till® works in perfect conditions; it also works in far from perfect conditions, like this season, without damaging the soil.

Significant Benefits

Our very heavy Hanslope Series chalky boulder clay soil is one of the most difficult to farm. When worked wet it can become impossibly sticky, unfriendly and slow to drain, then when dry it sets as hard as concrete. In both cases it is impossible to work, making it essential to carry out all field operations when conditions are right. When wetted, unhealthy soils ‘slake’, or run together, very quickly and they lack the natural glues that help bind the soil together. This blocks the natural pores and worm burrows in the soil, which can lead to ponding and waterlogging that can develop into erosion and loss of topsoil. Conversely, very dry conditions can lead to cracking, drying like concrete, inhibiting the crop from reaching its full potential.

Dick Neale from UK crop protection specialist Hutchinsons carried out a slake test at the Claydon farm last year and found our soils to be very healthy. He reported: “They have remarkable water infiltration rates, rooting depth and drainage due to the high porosity, low bulk density and abundant earthworm populations resulting from the tillage techniques employed. The natural aggregation, worms and invertebrate activity are all indicative of good biological health.”

See our slake test video at: www.claydondrill.com/video-gallery/ video/343 Next time I will discuss how our crops developed through the spring and how the Claydon TerraBlade inter-row hoe is used in conjunction with herbicides to help us minimise weeds and diseases.

To learn more about the Claydon Opti-Till® System and how to improve your farm’s p e r f o r m a n c e contact your local Claydon dealer, go to www.claydondrill. com or call the Claydon office on 01440 820327