THE FUTURE LOOKS BRIGHT

The past few months have been challenging for all of us. We were gearing up for a remarkably busy spring with more demonstrations than we could have imagined. However, the arrival of the Coronavirus and the ensuing lockdown meant early on we took the decision to cancel all Spring demos for the safety of our employees and the farmers we would have been demonstrating to.

All was not lost though we were still using the Virkar on our own farms and following on from the success of establishment in the autumn. We were looking forward to really testing it again this Spring and the results have been outstanding.

New for 2020

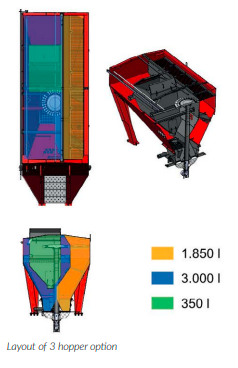

The Virkar Dynamic DC has had a few changes and new options for the 2020 season. It is now available in widths up to 7 meters, available with 3 hoppers, hopper extensions, and auger feed loading. As well as the new front cutting disc which really improves the drills capability in heavy chopped straw ground. There are now the options to be able to put tramlines in, and a factory fitted camera system with hopper camera and rear camera which improves the user experience. Also, we have developed over the past few months a more resistant spring compensator in the coulter, for heavier ground meaning you divert more pressure to the seeding tine and closing wheels meaning easier slot closure on heavier ground.

The new normal

I think it is now clear to see that our weather in this country is becoming harder and harder for us to achieve what we want as farmers. Months of wet followed by months of dry, means crops have been under a lot of pressure.

Having direct drilled Spring Oats Spring Barley & Spring Wheat, into a wide range of scenarios such as 5 ft tall buckwheat, oats, and phacelia cover crops, we were extremely impressed in how the drill dealt with the conditions. The ability to conserve moisture through No-Till in the Spring is becoming crucial. All our Spring crops that were direct drilled look extremely healthy and strong. Being able to drill the field using only 2.5 litres of fuel an acre and seeing a brilliant crop emerge knowing you have saved £25/30 acre over the previous system is a good feeling.

One Year on

Having now run our 6 Meter Virkar Dynamic DC for a whole season. It is clear to see that it has exceeded all expectations. It truly is one of, if not the most versatile & simplistic drill to operate. The results and interest we have received has been very encouraging.

Moving forward with the uncertainty around what the future holds for our industry, I think more so than ever NoTill is an attractive avenue to go down. For us with our own farming operation the Virkar has allowed us to significantly reduce our establishment costs whilst maintaining yields.

Looking ahead

We are already preparing for the Autumn demonstration season and hoping this time we can finally get the drill out and about on farms. We have had in the past few weeks and moving forward plenty of farmers visiting us seeing the drill first hand and having a tour of our farms and crops that have been drilled using the Virkar , they leave very encouraged by what they have seen.

They say a lot can change in a year, from seeing a video of the drill on YouTube, to now having drills out working across the UK. This machine is now a key part of our farming operation, by future proofing our business by ensuring we have the most cost effective and efficient system in place for crop establishment. We cannot wait to see where the next 12 months takes us.

New drill on the Horizon

New for 2020 is the direct disc coulter version of the drill. The Dynamic D has been a project that Virkar have been working on and thoroughly testing in tough Spanish conditions for 2 years.

The coulter design means it can mount into the same frame as the Dynamic drill meaning you keep the modular design, widths from 4.5 to 7 meters will be available with either 19 or 25cm row spacings. The coulter arms are maintenance free, sealed bearings and bushed. The coulter design means you get 35cm of travel for contour following, on the move coulter pressure adjustment, and only one manual adjustment per coulter leading to quick set up time in the field. Again, the drill can be specified with 3 hoppers and various other options.