DESPITE EXTREME WEATHER OUR CROPS LOOK FANTASTIC

Jeff Claydon, who developed the Claydon Opti-Till® System, discusses the progress of winter and spring crops on his family’s farm in Suffolk and how the TerraBlade inter-row hoe is used in conjunction with herbicides to help minimise weeds and diseases. This article was written during the first week of May, following the wettest winter since national records began in 1910 and a very dry spring.

The COVID-19 situation has made consumers much more aware that food is one of life’s most basic requirements and not something to be taken for granted. It has also highlighted the complexity of the finely tuned supply chain which delivers a continuous supply of high-quality food to retailers’ shelves for them to purchase. This presents the farming and food sectors that have Farm Assured standard and Red Tractor status with a real opportunity to better inform and educate them on this critical topic.

Continuous pressure from the supermarkets over many decades has forced food prices down in real terms, so as an industry we have had to respond by cutting costs and becoming more productive to remain profitable. But that has become increasingly difficult to do and going forward the situation will require careful consideration, because there is no point in chasing a low-cost system if yields are compromised as far more will be lost than saved. With profit margins under pressure, a shortage of skilled labour and more frequent extremes of weather, the financial risks attached to farming have increased substantially. Never has it been more important to operate an establishment system which is effective in all conditions and provides sufficient capacity to allow crops to be drilled at the right time, in the right conditions. Without those attributes it impossible to produce high yields and generate the financial returns necessary to farm profitably and sustainably.

A challenging season for many

This season’s extremes of weather highlighted the drawbacks of moving too much or too little soil. Many who relied entirely on a plough-based or min-till system are now questioning the relevance of multiple tillage operations, whilst the serious pitfalls of a no-till approach have been very evident. In both cases, less-than-ideal establishment, poor germination, and less effective weed control will ultimately reduce yields and profitability.

I am pleased to report that this has not been the case on the Claydon farm, where the Opti-Till® System provides much-improved timeliness and flexibility. All our crops are established with a 6m Hybrid T6c which comfortably averaged 40ha a day, so all 280 hectares of winter wheat, beans and oilseed rape went in as planned in just 70 hours. The winter wheat was in the ground by 31 October and the last winter beans were drilled on 19 November. Wider crop rotations, combined with a 50:50 split between wheat and break crops, have helped to spread the workload. After harvest we had plenty of time to carry out an effective stubble management programme with our 15m Straw Harrow and 6m TerraStar. This encouraged multiple flushes of volunteers and weeds, any remaining green material being killed off with a single application of full-rate glyphosate in October/November. For spring crops this left fields clean but with a shallow layer of surface tilth which provided ideal conditions over the winter and prevented the surface from capping.

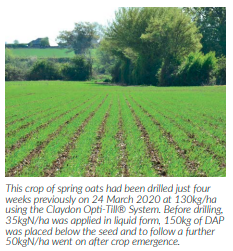

We drilled the remaining 46ha of spring crops directly into this perfect growing environment at the end of March. Following a week of dry weather our spring oats went in on 24 March, the day after ‘lockdown’ started in the UK, even though the soil temperature was just 5.5°C and significantly below the 7°C average for January. In the four weeks that followed we had just one rain event and the 2mm which fell evaporated quickly. In early April there were more frosts than during the whole of the winter and these, together with very cold winds, stunted the oilseed rape.

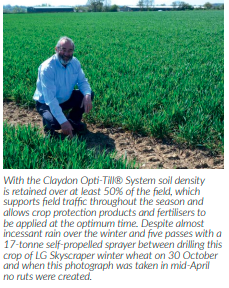

It is much shorter than normal, but prolific amounts of flowers and seed pods are evident, so plenty of sunlight will penetrate the canopy and hopefully help to ensure good yields. Without Opti-Till® our crops certainly would not be at the stage they are now. The system greatly improves timeliness, reduces establishment costs by up to 80%, creates well-structured, supportive soils, encourages high worm populations, promotes biodiversity, and ensures excellent drainage. This results in sustainable, high yields, greater resilience to extreme weather events, numerous environmental benefits, and improved profitability.

The key is the Hybrid drill’s patented leading tine which lifts and aerates the soil, creating fissures that alleviate localised compaction, improve drainage, allow the soil to absorb heavy rainfall without capping and provide space for strong rooting structures to develop. The separate seeding tine places seed within the band of soil which has just been lifted and loosened, providing ideal conditions for rapid emergence, and encouraging strong rooting structures to develop.

Drilling seed in bands provides an ideal environment in which worms thrive and because their burrows and capillaries are left undisturbed this aids drainage and water movement throughout the soil profile during growing season. Plant roots are also left largely undisturbed, which adds to the soil biota and improves its structure, organic matter depletion is minimised due to nominal soil disturbance, while moisture and nutrients are preserved. Setting any drill up correctly according to prevailing conditions is always important for optimum results, but it has been critical this season.

In the autumn it rained almost every day and so we slightly reduced the working depth of the front tines to prevent the tractor’s wheels from slipping excessively in the extremely wet conditions. This also helped to maintain a reasonable forward speed and achieve enough soil shatter, without bringing wet sticky soil to the surface. In the spring, when the soil had dried out on the surface but remained wet underneath, we also ran the leading tine 6cm to 8cm below the seeding zone to draw up humidity into that area.

Despite atrocious weather, with only three rain-free days from October until mid-March, crops established well and when I went around the farm this morning even the headlands looked exceptional. Our customers throughout the UK and overseas have reported that the Opti-Till® System has also produced excellent results. One of them called me to say that they had operated their 6m Claydon Hybrid around the clock to make best use of a period of dry weather in the autumn, drilling 80ha in a 24-hour period without the need for any form of precultivation.

Tidying up in spring

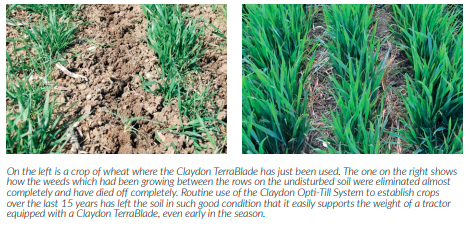

With all our winter and spring-sown crops in excellent order we have been making extensive use of our Claydon TerraBlade, a low-cost, mechanical method of controlling weeds growing between the rows in all combinable, band-sown crops. Keeping these areas clean during the early stages of crop growth reduces competition for nutrients, light, air, and water, enabling the young plants to grow strong and healthy, improving the availability and utilisation of soil nutrients and ultimately boosting crop yields.

The TerraBlade is an additional weapon in the agricultural industry’s weed control armoury at a time when the efficacy of some herbicides is decreasing, and the cost of control is increasing. It eliminates weeds reliably, safely without using chemicals and clears up any that were missed by agchems, or where such products cannot be used. This greatly reduces the return of weed seeds, the overall weed burden and the risk of more resistant types developing.

On farms that drill early, crops may be sufficiently well developed in the autumn to start using the TerraBlade then, and the operation can continue in the spring whenever soil conditions allow, up to the stage where the crop might be physically compromised by further passes.

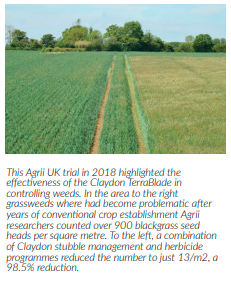

A trial by Agrii UK in an area where grassweeds had become problematic after years of conventional crop establishment found that a combination of Claydon stubble management and herbicide programmes achieved an exceptionally high level of control. In the area which received no treatment, Agrii researchers counted over 900 blackgrass seed heads per square metre. In the surrounding area, where a combination of ag-chem treatments, Claydon Straw Harrow and Claydon TerraBlade passes were used, the number was just 13/m2, a 98.5% reduction.

The benefits of the Opti-Till® System are clearly resonating with farmers and this has been reflected in the high number of enquiries that we have received in recent weeks as many decide to revaluate their approach before the autumn. The COVID-19 lockdown meant that we were unable to welcome the hundreds of existing and potential customers who normally visit our open days in May, so this year we decided to film a virtual open day so that we could highlight just out well our soils and crops are looking. You can view it by visiting the Claydon website (www. claydondrill.com)

To learn more about the Claydon Opti-Till® System and how to improve your farm’s performance contact your local Claydon dealer, go to www. claydondrill.com or call the Claydon office on 01440 820327.