The main thing to understand is that an electric fence is a psychological barrier for animals. The initial electric shock they receive means they are deterred from approaching the fence again. Therefore, how a fence is erected and the speed with which it can be moved is critical when consider what is important in terms of using them to help graze crops. In this guide we will with the help of Rappa introduce the elements of a fence and what you would need to be able to graze your crops (so you just need to add the animals).

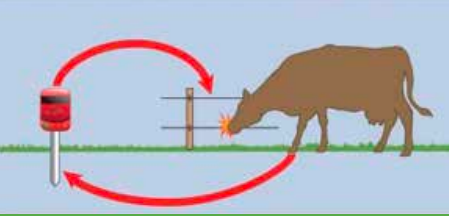

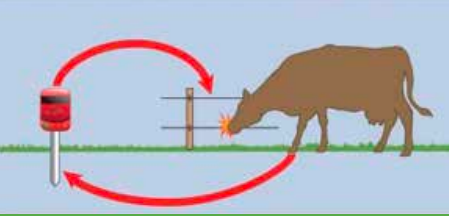

As you are already probably aware, an electric fence is made from three elements:

Energiser – generates a regular pulses of electrical current

Wire – conducts the current

Earth – returns the current back to the energiser.

Energisers

The energiser converts electricity from mains supply or batteries into high voltage pulses of electric current at one second intervals, that travels along the fence. The type of energiser you need depends on how close the fence is to a mains electricity supply, the fence length and the type of animals you want to control.

Wire

There are many variations of wire suitable for electric fencing.

• Steel wire, either single or multistranded, is strong, durable and highly effective at conducting electricity, so the animal receives a greater shock when touching the fence. Steel is heavier than other alternatives, and is best used in permanent or semipermanent fencing where you need good tension on the wire.

• Polywire is lighter than steel. It is made from UV-stabilised plastic twine with three or more strands of stainless steel wire woven into it. Polywire is designed for temporary fencing and stripgrazing, although the more substantial polyrope can be used for permanent fences.

• Polytape and polybraid consist of stainless steel wires and plastic strands woven into a ribbon, available in a range of widths and colours that can be used for permanent and temporary fencing. Both are highly visible, but can be vulnerable in high winds..

Wire Reels

A reel allows you to unroll the fence wire evenly without creating potentially damaging kinks, then roll it up again neatly for reuse. By locking firmly onto a reel post, the reel keeps the fence wire taut. We offer two kinds of reels:

• Rappa Reel – for use with our Rappa Fencing Machines

• Hand Reel – for manual fencing

Posts

Permanent fences use timber posts to support the wire, while temporary fences rely on metal or plastic posts, available in different heights and spacings, depending on the stock you want to fence. In addition, anchor posts are used for temporary fencing in the corners or at the beginning of a fence, and help keep tension on the fence wire. Temporary fences also require a reel post at the end to hold surplus wire and keep the line taut.

Insulators

Insulators keep the fence wire from touching the supporting post or stake, preventing electricity leaking back to the ground. Anchor or endstrain insulators also take the strain of the wire at the end of the fence line or at corners. Polyposts are made of non-conductive plastic therefore separate insulators are not required. Good quality insulators should be smooth and dry off easily to prevent moisture collecting in nooks or cracks causing current to leak, creating an ‘arc’. Arcing, which produces a regular clicking sound, reduces the effectiveness of the fence. Offset insulators give a longer life to permanent fencing by holding the electric wire a short distance away from a new or existing permanent fence, stopping animals causing damage by biting, leaning or rubbing.

Earth stakes

Earth stakes are inserted into the ground and attached to the energiser. They ensure the power returns through the ground and back to the energiser when an animal completes the circuit by touching the fence.

Fence Tester

All electric fences need regular maintenance. You should regularly measure the power on the fence lines using a fence tester – or voltmeter – that will help locate any problem areas where power is leaking away.

Electric fencing machines

While fences can be put up manually, there is certainly skill involved. Automating the process with a machine, will help keep the wire taught and visible and reduce the chance of accidental grounding. Electric fencing machines, also known as winders, are used to erect and dismantle up to four lines of fence wire quickly and efficiently, perfect for strip or cell grazing where fences are moved frequently – a typical 600m electric fence can be put up in 20 minutes and dismantled in 10. Rappa’s fence winders have been developed and built in the UK for the last 40 years, and now include a range of six machines, from manual-push barrow winders for small or inaccessible areas, to larger models that fit onto an ATV or RTV – from human to horse power! The RTV Winder is designed to pick-up on the left hand side so the fence can be dismantled without leaving the seat of the cab. The largest in the range, the Trailer Winder, can fence up to 5km in one hit, again this can be specified to pick-up the fence on either the left hand or right hand side. A complete range of fence packs have been developed to compliment the fencing machines.

Installing an earth

First, work out how many earth stakes you need. Larger fence energisers exerting more power, or longer fence lines with higher leakage, require substantially more earthing. As a rule aim for 1 metre of earth rod for every joule of energy, ie. a 5 joule energiser will require 5 metres of earthing. You need to link your earth stakes together with underground cable, which is then connected to the energiser’s earth terminal. Your earth stakes should be at least 4 metres apart, and kept well away from domestic earth systems, and at least 10 metres distance from any other earth installations, such as those used by telephone or electricity supply companies.

Never use steel water pipes or steel-framed buildings as an earth. You also need to place your earth system in a consistently damp site. In areas where the soil is very dry, or there is a lot of sand, peat, gravel, snow or frozen ground, you can boost the efficiency of the stake by watering the ground in dry weather or increasing the number of earth stakes. You can also run an earth return wire parallel to the fence line, and connect it to earth stakes at regular intervals. Bear in mind that an earth system installed in winter, which is adequate for winter conditions, may not be suitable for summer; this may explain any substantial loss in power on your electric fencing over the summer months.

Safety in electric fencing (the things you should and shouldn’t do)

Properly installed and maintained, electric fencing is safe for humans and animals. However, you must adhere to the following:

• Never electrify barbed wire or any other material that could entangle an animal or person.

• Never attach more than one energiser to a fence. Maintain a gap of at least 2 metres between separate electric fences.

• Put up warning signs at intervals of no more than 10 metres on any electric fence installed along a public path or highway, or at any other point where people may encounter the fence.

• Where your fence intersects a footpath or highway, you must incorporate a non-electrified gate or stile to cross the fence. • Never install connecting leads (underground cable) in the same conduit as mains supply wiring, communication cables, or data cables.

•Avoid running electric fences parallel with overhead power or communication lines, as it may induce a dangerously high voltage on the fence line. When crossing under power lines do so at right angles and make sure the fence height doesn’t exceed 2 metres.

• Install a mains fence energiser under cover, near a mains supply. Make sure it is out of reach of children, and away from flammable materials.