Dr C John Baker, Feilding, NZ

If you want to start a pub debate amongst farmers, try telling them which direct drilling (no-tillage) opener is the best. Everyone has an opinion. Here are some of the problems that direct drilling openers have to cope with, plus summaries of what published science and field practice tells us about how close each generic opener type comes to fulfilling those functions. This is an opportunity to sort fact from fiction. Please note, this author uses the terms direct drilling and no-tillage synonymously. It is helpful to firstly understand that the functions we have asked drill openers to do have changed over the approximately 60 years since the first attempts at direct drilling were reported in the 1950s.

• In the 1950s, the main purpose was to introduce new and improved pasture species into cloverdominant pastures in New Zealand’s Central Plateau without tilling the soil.

• In the 1960s and 1970s, the main aim changed to reducing wind and water erosion in North America and reducing on-farm costs and historical soil compaction in arable soils in the UK.

• By the 1990s and early 2000s, although the original soil erosion and cost objectives remained, emphasis shifted to making food production sustainable.

• Now the objectives have morphed further into reducing Green House Gas (GHG) emissions and regenerating soil health, plus all of the above.

Early direct drilling demanded disc openers because of their ability to handle residues. But most disc openers at that time produced patchy establishment and were expensive and difficult to use. So farmers gravitated to tined or shank-type openers over time. In the UK, the chemical company ICI Ltd (now part of Syngenta) sparked a lot of the early

developments.

ICI had developed the herbicide paraquat but no European machinery company was prepared to design a special drill for untilled soils. ICI therefore designed its own triple disc openers. But these turned out to be so limited in their functions that everyone in Europe eventually gave up direct drilling altogether and reverted to minimum tillage, because it did not require a special drill – just shallower tillage tools.

Fermentation of “hairpinned” straw, slot wall compaction, difficulty in closing the slot, stimulation of unwanted grass seed germination and an inability to band fertilizer separately from the seed, were just some of the shortcomings of triple disc openers. Most USA drill designers simplified the design of triple disc openers to double disc openers and also introduced single angled disc designs. But these only partly overcame the shortcomings of the original triple disc design. On the other hand, Argentina and Brazil managed to live with triple (and double) disc openers, mainly because their soils and climates are so kind that it is difficult to fail with any opener design. Australia and North America were the first arable countries to abandon disc openers in favour of simple shanks or tines.

While these designs allowed fertilizer banding to be added to the list of desirable functions, tines disturb a lot more soil than most discs and block with long residues. This, in turn, severely limited the opportunity to use crop residues as a mulch to smother weeds, reduce evaporation, control the slot microenvironment and re-stock the soil with photosynthesised carbon.

Tined openers made crop residues into a partial enemy of no-tillage systems rather than their greatest asset. Their limitations in this regard forced farmers to change their notillage cropping practises to minimise the amount of residues that tined openers had to cope with. Burning made a comeback and other practices included pushing the residues aside, chopping them into shorter lengths and even burying them in vertical trenches. Most of these actions either required an additions pass over the field with a separate machine or demanded additional power from combine harvesters when they were asked to chop the residues during harvesting.

Over time, tined no-tillage openers have become synonymous with strip tillage because many farmers take comfort from seeing the seeds embedded in tilled strips of soil as they used to in fully tilled seedbeds. But the science shows clearly that re-positioning residues (chopped or un-chopped) over the sown slots in otherwise undisturbed slots (in order that the mulch of residues forms the top layer of the slot-covering medium with little soil visible) is one of the best things a no-tillage opener can do. It traps soil water vapour (humidity) in the seed slot itself, creates a barrier against the soil-discharge of CO2 into the atmosphere, and sequesters new carbon into the soil for the first time since mankind began arable farming on a large scale.

These are scientifically proven facts that are very significant for several reasons:

a) The world’s arable soils have already lost approximately 75% of their organic matter from oxidation caused by repeat tillage and other soil disturbance.

b) The residues left after harvesting arable crops are rich in carbon that has been re-captured from the atmosphere by photosynthesis. If left to decompose on the surface of undisturbed soils, this carbon is taken back into the soil by earthworms and other soil fauna.

c) All undisturbed soils contain 100% relative humidity in the pore spaces between individual soil particles, even when very dry.

d) Most seeds can germinate in 90- 100% relative humidity, even in the absence of liquid water.

e) All soil disturbance (including strip tillage) allows this pore space humidity to escape.

f) Because we have tilled soil for centuries (and thereby eliminating the role of pore space humidity) we have come to believe that seeds only germinate in contact with soil.

g) But it is no accident that the world’s network of seed testing stations germinate their seeds on blotting paper where there is no soil present at all.

h) In the field, untilled soils therefore have two moisture resources for germinating seeds, vapour and liquid water. Tilled soils have only one, liquid.

i) Strip and minimum tillage simply eliminate one of those germination resources altogether and therefore defeat one of the main objectives of no-tillage in the first place.

j) Not only does strip tillage allow water vapour to escape it introduces excessive oxygen to the soil, which re-oxidises soil carbon into CO2, that escapes at the same time.

Mankind has therefore inadvertently moved backwards in its otherwise understandable preference for highdisturbance no-tillage openers. We must now move back towards lowdisturbance no-tillage Against this background of conflicting problems and solutions, this author spent 30 years identifying and mitigating the issues that had been hampering direct drillers from the outset. Some 30 graduate students and numerous fellow scientists at New Zealand’s Massey Universities published a multitude of research reports in the international scientific literature that explain the many hitherto unstudied interactions between machines, soils, seeds, seedlings, fertilizer, growing plants, weeds, and pests. For those practicing no-tillage, the following list of issues might be familiar:

1. My drill or planter only works well if some prior surface tillage has taken place.

2. I only get reliable establishment if I cause maximum slot disturbance with the openers.

3. Most of the time I get lower crop yields that when I practiced tillage.

4. Although I get reasonable germination when the soil is crumbly, I get only patchy results when the soil is wet or even sometimes just damp.

5. I find that although crumbly soil is preferable, it is also drier and this sometimes creates germination problems if I don’t get rain or can’t irrigate immediately after seeding.

6. Where irrigation is available, I nearly always irrigate after notillage seeding.

7. In damp soils, although I can usually get adequate seed cover, I am often left with poor establishment when the soil dries after drilling causing slot shrinkage that exposes seeds. 8. I find that the timing of no-tillage drilling or planting is critical.

9. I find that my machine will direct drill some crop types well, but is limited with other.

10. I find I often have to make significant adjustments to the openers when going from one field to another, or even sometimes in the same field when conditions change.

11. I have had to modify the drill or planter openers significantly since purchasing the machine in order to make the machine work best in my soils.

12. I find that my machine works fine on flat land but is not very effective on hillsides.

13. I frequently have difficulty drilling into sod or dense pasture.

14. Stony soils cause numerous breakages and other problems with my machine.

15. My machine can cope with stones but in doing so brings many of them up onto the surface.

16. The soils on my farm have become more difficult to drill since I changed to no-tillage.

17. I seldom see 70% or greater residue-cover over the slots after drilling or planting.

18. I often find I have retained less than 50% of the residues that were there before drilling.

19. Getting good seed-to-soil contact is often an issue for one reason or another.

20. I try to avoid spring drilling if at all possible because establishment is problematical.

21. I restrict my no-tillage to lowvalue crops, cover-crops or pasture and seldom risk it with high-value crops.

22. My machine has difficulty handling heavy residues without blocking.

23. In addition to spraying, I nearly always need to pre-treat the residues or soil in some way before drilling or planting.

24. My machine handles chopped straw, sod or standing stubble OK but has difficulty with long un-chopped residue or straw, especially if it is damp.

25. I never attempt to direct drill through long rank grass or weeds without at least a 6-month spray-fallow beforehand so the residues can decay somewhat.

26. I frequently get residue blockages that are sufficiently severe to require stopping.

27. My machine physically handles residues OK but has difficulty avoiding hairpinning (tucking) of uncut straw into the slot, which in turn affects germination.

28. The way that my openers handle residues is to push them to one or both sides of the row.

29. My machine cannot position seed and fertilizer in separate bands at seeding.

30. I would like to drill in narrow rows but my machine can’t band seed and fertilizer separately in narrow rows so I am forced to drill in wider rows than desirable or broadcast fertilizer.

31. My machine can position seed and fertilizer in separate bands in some soils and at certain drilling speeds, but not in other soils or at other drilling speeds.

32. My machine can position seed and fertilizer in separate bands but uses two openers per row to achieve this, which increases soil disturbance.

33. My machine could not be described as a low-disturbance no-tillage drill or planter.

34. Seeding depth varies noticeably across the field, especially where the surface is not smooth.

35. My machine cannot seed consistently shallower than 1” (25 mm) without risk of the openers riding out of the ground altogether in some places.

36. I have difficulty getting enough downforce on the openers when the soil is hard or dry.

37. I cannot vary the downforce on my openers without leaving the tractor cab.

38. My machine is not capable of constantly and automatically increasing and decreasing the downforce applied to the openers on-the-move to match soil hardness.

39. I find I need to seed deeper than desirable in order to be sure of getting adequate covering.

40. The maximum speed I can seed at is seldom greater than 5 mph (8 km/hr).

41. My openers stimulate too much weed seed germination. 42. There are a large number of greasing points on each opener that need frequent attention.

43. I expect that the useful life of my current drill or planter will be less than 5 years.

44. I experienced a reduction in crop yield during the first few years of direct drilling.

45. Even after several years of direct drilling, my crop yields seldom beater tillage yields.

46. I do not believe that no-tillage opener design can influence crop yield.

47. Purchase price is more important to me than the machine’s potential to influence crop yield.

48. My dealer does not seem to know a lot about no-tillage as a farming practice.

49. I find no-tillage to be altogether more risky than tillage.

50. If it wasn’t for the environmental issues, I would prefer to go back to conventional tillage.

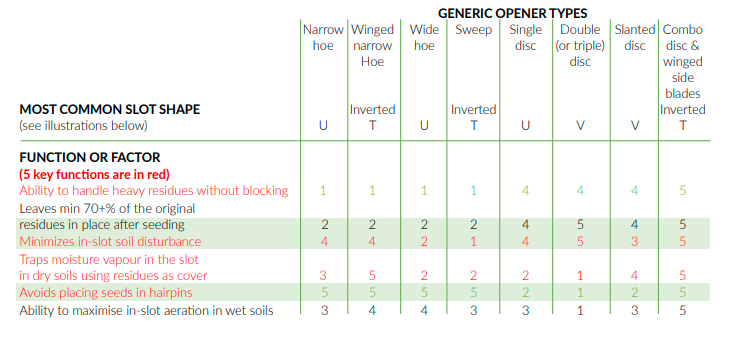

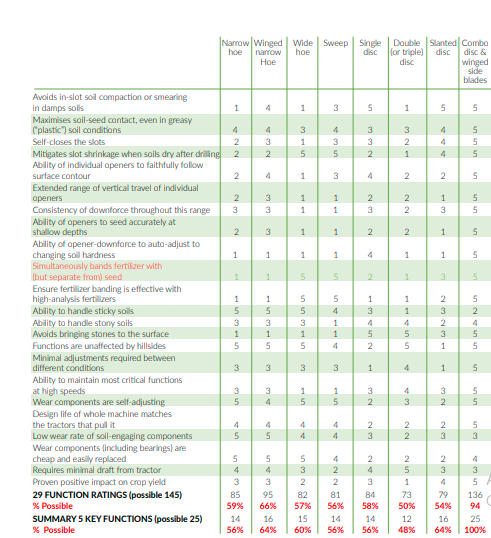

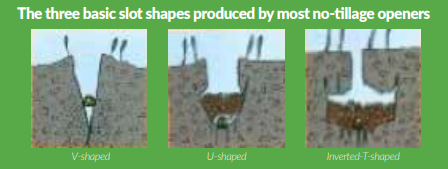

Our research sought to mitigate as many of these issues as possible and the results can be seen in the Table below, which quantifies how well (or badly) 8 generic no-tillage opener types perform 29 identified functions. Five of these functions (shown in red) are considered to be vital to all no-tillage cropping.

COMPARISONS OF 8 GENERIC NO-TILLAGE OPENERS BY FUNCTION

CONCLUSION:

• 5 of the 8 generic no-tillage opener types (63%) performed little more than 50% of the 29 desirable functions listed.

• 3 of the 8 (38%) performed about 2/3 of the 5 vital functions listed.

• Only 1 of the 8 (12%) performed all of the vital functions and 90% of the desirable functions.

OVERALL CONCLUSION:

Most people are little more than half way towards mastering true notillage or direct drilling – but at least they are that far. And half way means progress in the right direction. Keep learning!