ENERGY & ROW CROPS, STRIP TILL AND SOIL HEALTH, BY GEORGE SLY

A lot of the attention on no-till and zerotill is on cereal grain production and it is very encouraging as a manufacturer to see so many enquiries for our Boss drills both in the UK and Europe. Less focus is on the fresh foods we enjoy every day such as root veg, salads, potatoes, sugar beet and energy crops such as maize. All of these generally have very intensive tillage regimes as the “risk” is seen too high to venture off the beaten path. As well as being a shareholder in Sly as an equipment manufacturer I also farm 280 hectares of clay/silt land at Gedney Hill near Spalding in Lincolnshire. We are cropping Winter Wheat, Winter Triticale (Forage), OSR, Maize (Forage), Sugar Beet and Spring Oats . All our cereals are either scratch till or no-till and are drilled with our Sly Boss 6m drill.

All our row crops (Maize, S.Beet and OSR) are planted either no-till with our precision planter or behind strip-till with our precision planter. There Is no ploughing or full surface deep cultivation. This means we are doing the very least amount of cultivation we can with trickier crops. We are also placing fertiliser very accurately and growing cover and companion crops.

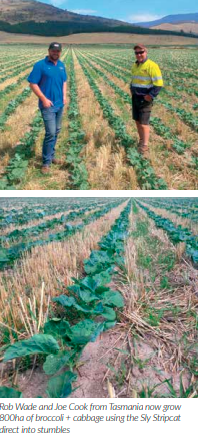

We are pushing the boundaries of strip till technology for maize production, and we have had very encouraging results so far, I am confident we can match yield on any conventional crop on the same soil with strip till versus conventional providing it is managed correctly with significantly lower costs. 55,000Ha of maize is grown for A.D now in the UK and its vital we do this as efficiently as possible to avoid bad press. In 2019 we will try to use this same system on salads, vegetables and pumpkins in the UK. We have a customer in Tasmania that grows 800Ha of Broccoli and Cabbages and they are now 100% using the Stripcat for tillage and fert placement. Meaning a 70% reduction in tillage to produce a large part of Melbourne and Sydney’s winter veg.

Benefits of Strip till include:

• Up to 70% reduction in overall diesel use

• Less capital in expensive high horsepower equipment

• Up to 40% reduction in fertiliser use by placing it accurately

• Up to 60% reduction in damage by harvest traffic (a major issue with UK Maize)

• Cultivate 30% of the field not 100%, you are only tilling where the plant will grow

• Reduced run off

• Improved use of rainfall (water runs into the strip)

Image below shows the result after one pass with the Sly Stripcat 2 utilising offset coulters to plant the interrow with a cover or companion crop. The oil radish and oats are in the inter-row and the tilled strip is where maize will be planted in 6 months time. In theory this field is being fully cultivated, half by plant and half by machine. Interestingly the radish managed to “loosen and aerate” about 20 cm deeper than the tine was running when we did a test dig in the spring.

Combining Strip till with the very latest in planter technology can ensure the success of the system. At Sly we are working with precision planting in the USA who manufacturer control and sensory technology for planters. Our first planters are working on my farm and my partners farm in France and we have been amazed at the performance.

The planter features:

• Row by row downforce control, even in rougher conditions on strip till our seed depth uniformity is above 95% (depth is more or as important as spacing)

• The Smartfirmer (A sensor running in the seed trench) is monitoring organic matter, soil moisture, soil temperature and furrow cleanliness and uniformity and adjusting population and fertilisation levels on the move.

• Furrowjet is allowing us to fertilise both in furrow and both sides of the furrow whilst planting. We are giving the plant both starter fertiliser and its early-mid stage requirement and placing it with extreme accuracy.

All these small things we are monitoring by hand harvesting the crops that have been given different treatments. The Stripcat 2 units and planter units are available from 4 to 18 rows, 2m-12m versions and from 40-125cm row spacings. They can either be together on a trailed machine or as separate toolbars. On lighter soils it is possible to combine both strip till and planting. On heavier soils it is always advised to separate the two jobs. Our planter units are expected to be commercially available from mid 2019.

We do hold open days at our farm and if anyone wants to see what we are doing we welcome visitors.