Catchy harvest brings numerous challenges

Harvest was a real snatch and grab affair with numerous challenges for Jeff Claydon, Suffolk arable farmer and inventor of the Claydon Opti-Till® direct strip seeding system.

In my last article for Direct Driller, written 27 May, I reflected on the dramatic contrasts between this season and last, both in terms of the weather and the finances of farming. Those extremes were evident right through to harvest and continue heading into autumn, but despite the numerous challenges as farmers we have little alternative to growing crops. The agronomic, meteorological, political and economic headwinds are likely to further test our resolve in the months ahead, so all we can do is to farm as efficiently as possible.

Between New Year’s Day and the end of July last year just 244mm of rain fell. The exceptionally dry conditions resulted in our earliest-ever harvest and the combine ran uninterrupted from the time it cut the first oilseed rape in mid-July until the last of the spring oats fell to its 12m cutter bar at the start of August.

It was a fast, efficient operation, combine, tractors and trailers caused no damage to the soil, while the heat from that great natural dryer in the sky kept grain moisture levels low and costs to a minimum. One downside of the prolonged hot spell was that by mid-August it was too dry to drill oilseed rape and we could not begin stubble management because nothing would germinate.

In complete contrast, during the same period this year total rainfall was 436mm, harvest started 10 days later and by 2 August we’d only managed to combine the oilseed rape and two-thirds of the spring oats.

Having looked so promising at the start our oilseed rape faced an uphill struggle throughout the remainder of the season, a scenario which seems to have been the case on farms across the country regardless of the establishment system used. The decision not to apply slug pellets early was our first mistake and we lost plants as a result. The second was to drill at the end of August just before the cabbage stem flea beetle came through. The third was to not spray off the entire crop as soon as we knew it wasn’t heading in the right direction and redrill with spring oats or wheat.

We lost a third of our 61ha of DK Excited to cabbage stem flea beetle and slugs, the area being redrilled with spring oats in April. On that which made it through to harvest we applied glyphosate, but the crop was slow to take it up and moisture contents varied from 6% to 12%, delaying combining by a week or so. Pest damage significantly reduced pod numbers and ultimately yields were decimated, the remaining 40ha of oilseed rape yielding just 64 tonnes. It won all the awards for our worst oilseed rape crop ever!

Given how good it had looked in November that was very disheartening. We lived in hope, but after cabbage stem flea beetle massacred the crop, it never recovered. The million-dollar question I asked myself in the aftermath of harvest was ‘are we brave enough to drill oilseed rape again this season?’

On the one hand the crop is early to harvest, we can move it out of store quickly which benefits cash-flow, while establishment costs are low. Ultimately growing costs are very high and front loaded, which increases our risk exponentially, so on the face of it at under £400/t the crop doesn’t look exciting. On the other hand, with potentially a much smaller area being drilled this season what price a tonne of the stuff this time next year?

In what was a very last-minute decision taken purely for agronomic reasons we decided to drill the same area of oilseed rape for 2023/24, although time will tell whether that was the right call. The big unknown is how big an issue cabbage stem flea beetle will be, but we were able to get the crop in the ground by mid-August so it could be okay. What’s certain is that we’ll be ruthless about terminating it early if problems develop and before incurring the cost of Kerb®.

By way of contrast, the 77ha of Elsoms Lion spring oats drilled with our new 6m Claydon Evolution in excellent conditions during February proved exceptional. Standing tall right through to harvest, they yielded 7t/ha on our benchmark ‘80-acre’ field where the drainage is spot on and gave us more time to control any stubborn weeds before the following crop of wheat went in. In contrast, some areas in the adjacent Mill Lane field where the drainage requires attention yielded just 5.9t/ha, highlighting the importance of getting water away.

KEEPING BLACKGRASS AT BAY

Last summer, conditions were so dry that weeds and volunteers were very slow to germinate. The warm autumn allowed weeds and volunteers to keep growing and they continued to germinate throughout the winter, so one lesson learned was the value of controlling them before Christmas.

With a week of wet or catchy weather forecast for the second week of August it was too wet to combine our remaining crops or even use the Straw Harrow to start stubble management. I had to console myself knowing that weed seeds and volunteers would start to germinate due to the abundant moisture and be in ideal condition to be taken out when we could get back on the land.

It is impossible to carry out too many passes with the Straw Harrow, as highlighted by the performance of our spring oats. After four or five passes with this fast, cheap-to-operate implement, far fewer weeds remained, and the spring oats were at their very best. Where we did two passes then sprayed off green material in the autumn another flush came through in the spring and we had to go in with another dose of glyphosate. Apart from the additional cost the yield after two passes was 2t/ha lower than where we did four.

The experiment proved that it’s a bad idea to leave stubbles green over-winter. Over-wintering blackgrass seems to have a toxic effect on the soil and subsequent crops, so it’s critical to take them out while still small as they become much harder to remove once established.

Previously I mentioned how using the TerraBlade inter-row hoe had made a considerable difference where it was used in one of our fields where Agrii had a blackgrass trial. The moist soil conditions in spring were less than ideal for using it so I was rather surprised that it took out a significant percentage of the strong blackgrass plants growing between the rows and reduced the number of viable blackgrass seed heads by 60 per cent. It just goes to show how important the TerraBlade is, either when used in conjunction with herbicides or in organic / regenerative farming situations.

Our patchy, uncompetitive oilseed rape allowed grassweeds to proliferate, the problem compounded by the low seed rate and plant numbers characteristic of a hybrid variety letting more light permeate through the crop. Following this with wheat will bring its own challenges, but on heavy ground such as ours what alternative is there?

NO RECORDS BROKEN

When drilling some of our wheat in mid-October to help combat grassweeds we used considerably higher rates to compensate for the fact that the seeds would have less time to develop. Our 200ha of winter wheat, all LG Skyscraper, subsequently came through the winter in excellent condition and even though by mid-February we’d yet to apply any liquid nitrogen it never looked ‘hungry’ and retained a lovely deep green colour. At the end of May it still looked fantastic and was full of potential, just as we wanted, but it would be the second week of August before any was harvested, at which point it became clear this would not be a record-breaking harvest, or even come close.

Last year, despite the driest spring/summer in decades and applying up to 25% less nitrogen due to a combination of soaring prices plus restricted availability, our winter wheat averaged over 10t/ha, oilseed rape 4t/ha, and spring oats 6.11t/ha. At the time of writing (18 August) just over half our wheat area has been harvested and averaged 9t/ha, significantly below our long-term figure of just over 10t/ha. With November 23 wheat currently trading at £173/t the shine has certainly come off last year’s results.

Partly the lower yield can be attributed to the fact that we cut back on nitrogen, applying 180-190 kgN/ha instead of our normal 240-250 kgN/ha. However, more likely it’s due to a combination of things, herbicides being less effective in the cooler, damp conditions, a lack of sunlight throughout the growing season, plus a late flush of blackgrass which took advantage of the moist soils to grow.

Many farms throughout the country, not just those on heavy land, are seeing grassweeds where they’ve been before, so we will do our best to control them through good stubble management, cultural means and inter-row hoeing, along with other options and tools. The Straw Harrow has done a fantastic job of germinating weeds and volunteers, so we will carry out multiple passes and apply glyphosate pre-drilling.

Good drainage is critical to get the best from our heavy clay soils and the wet weather highlighted any problem areas by attenuating variations in yield. The impact of less-than-optimal drainage was particularly evident in one field where the headland was shaded by trees and lay wet all season. There the combine’s yield meter recorded just under 7t/ha, but as we moved away from the lea of the wood it jumped to over 9t/ha, so perhaps we will consider one of the environmental schemes there.

Catchy weather meant that harvesting operations inevitably caused some compaction, although this was minimal by most standards due to the supportive nature of our strip seeded soils. Importantly, the leading tines on our 6m Claydon Evo drill will remove any compaction ahead of the seeding tines so that seed is placed into ideal conditions and grows away rapidly.

In my next report I will go through our complete harvest results and discuss how we got on establishing all the winter crops.

The Claydon website (claydondrill.com) galleries contain numerous videos on soil health and resilience, as well as showing the Claydon Opti-Till® System being used to establish all types of crops, in all situations, both in the UK and overseas. You can also keep up with the latest posts, photographs, and videos from Claydon and its customers through the Claydon Facebook page www.facebook.com/Claydondrill

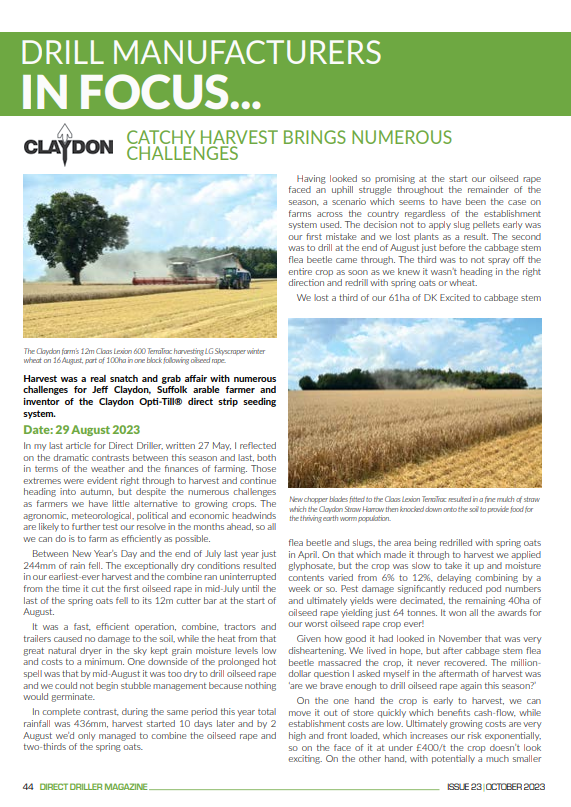

The Claydon farm’s 12m Claas Lexion 600 TerraTrac harvesting LG Skyscraper winter wheat on 16 August, part of 100ha in one block following oilseed rape.

New chopper blades fitted to the Claas Lexion TerraTrac resulted in a fine mulch of straw which the Claydon Straw Harrow then knocked down onto the soil to provide food for the thriving earth worm population.

Despite wet weather at harvest the combine left hardly a mark thanks to the good load-bearing structure of the soil.

Spring oats were a star performer, February-drilled Elsoms Lion yielding 7t/ha and a high quality sample.

Wet weather in August provided ideal conditions for mole draining.

April-drilled spring oats around the edge of this field were well behind those which went in during February and had already been harvested when this photograph was taken.

It is impossible to carry out too many passes with the Claydon Straw Harrow, this being the largest 15m version.