Written by Lizzie Sagoo from ADAS

Earlier this month, ADAS, Rothamsted and Bangor University welcomed over 250 delegates from 25 countries to the 18th International RAMIRAN conference in Cambridge. The theme of this year’s RAMIRAN was maximising the utilisation of organic fertilisers against a background of changing regulation and increasing pressure on the environment and food production.

Following on from the conference, our soils and nutrients team have outlined key learnings for growers looking to maximise the value of the nutrients contained in organic materials:

1. Know the nutrient content

Accurate information on the nutrient content is essential for making the best use of organic materials. ‘Standard’ or ‘typical’ figures are available in Section 2 of AHDB Nutrient Management Guide (RB209). These are average figures based on the analysis of a large number of samples. However, the nutrient content of organic materials will vary depending on factors, such as livestock feed composition, variable use of bedding, storage period and for slurries dilution by rainwater.

If possible, get a laboratory analysis of organic material. A laboratory analysis should include dry matter, total nitrogen (N), Phosphorus (P), Potassium (K), Sodium (S), Magnesium (Mg) and Ammonium-N. For poultry manures, also include uric acid N.

2. Minimise nitrogen losses

Wherever possible, applications of organic materials should be managed to minimise nitrogen (N) losses to the environment. The risk of N loss is greatest following the application of high readily available N materials such as livestock slurries, poultry manures and digestate.

Minimise the risk of nitrate leaching losses by applying high readily availabile N materials in the spring/summer rather than the autumn/winter period. If applying in the autumn, spread to crops with an autumn N requirement such as oilseed rape and grass. Reduce ammonia volatilisation losses by applying slurries or digestate with bandspread or shallow injection rather than broadcast equipment, or by incorporating organic materials soon after application.

3. Know your application rate, and spread accurately and evenly

To calculate the application rate, you need to know the capacity of the spreader and number of ‘loads’ spread over the field area. Or alternately for slurries, apply using a pump with a known output. For solid materials, the best way to assess the capacity of the spreader is to weigh it empty and then full.

Make sure the organic material is spread accurately and evenly. For broadcast spreaders, this means overlapping the bouts to get an even application across the field. Generally overlap the bouts by about half (this means the bout width is about half of the spreading width).

It is recommended to check your application rate and evenness of spread at least annually. However, data from Defra Farm Practice Survey indicates that only 35% of farms that spread manures using farm equipment adequately calibrate their spreaders. Half of farms that spread manures never calibrate their manure spreaders.

4. Build your farm nutrient management plan

Management strategies that minimise environmental N losses can maximise crop N recovery and increase the fertiliser N replacement value of the manure. This reduces the need for manufactured fertiliser application to meet crop requirements. In order to realise the value of manure applications, it is important to accurately predict the crop available N supply and reduce inorganic fertiliser use accordingly.

Section 2 of the AHDB Nutrient Management Guide includes guidance on crop available N supply from organic materials. Alternatively, farmers can use the MANNER-NPK software. MANNER-NPK (MANure Nutrient Evaluation Routine) is a decision support tool to quantify manure crop available N supply and is available to download for free from www.planet4farmers.co.uk.

5. Pay attention to phosphate and potash supply

Although much of the focus of manure management is on minimising the N losses to maximise N available to the crop, in the majority of cases, phosphate and potash supply is worth more than the N value. A typical 50 m3/ha spring application of cattle slurry will supply 46 kg/ha crop available N, 60 kg/ha P2O5 and 125 kg/ha K2O, and is potentially worth up to £135/ha in saved fertiliser costs (see below table).

In order to make the most of the phosphate and potash in manures, farmers are encouraged to target applications to fields where the soil is low in phosphate and potash, and as a replacement for inorganic phosphate and potash fertiliser.

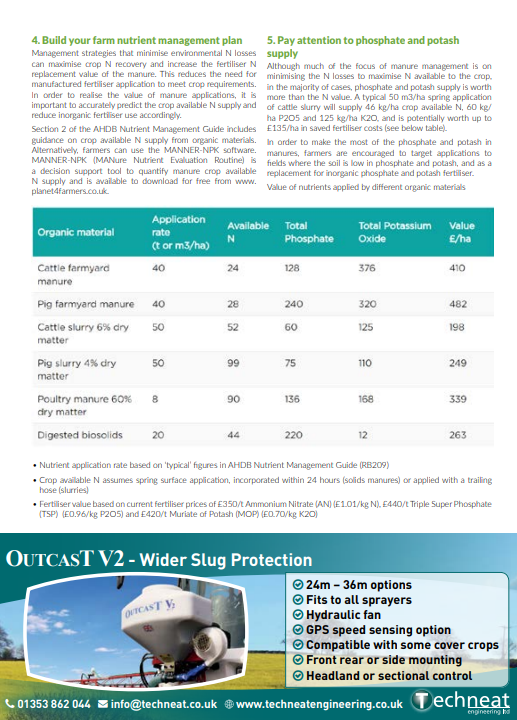

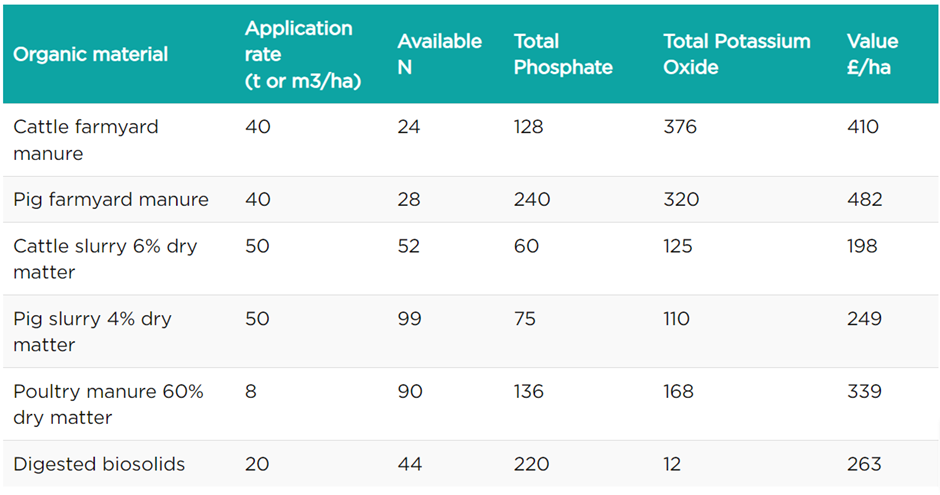

Value of nutrients applied by different organic materials

- Nutrient application rate based on ‘typical’ figures in AHDB Nutrient Management Guide (RB209)

- Crop available N assumes spring surface application, incorporated within 24 hours (solids manures) or applied with a trailing hose (slurries)

- Fertiliser value based on current fertiliser prices of £350/t Ammonium Nitrate (AN) (£1.01/kg N), £440/t Triple Super Phosphate (TSP) (£0.96/kg P2O5) and £420/t Muriate of Potash (MOP) (£0.70/kg K2O)