Written by Mark Atkins of Bio Farming Limited

In 2015 a colleague who operates a company supplying various biological based products into the agricultural market

asked if I could make a product from him as his current supplier was increasing costs that would take it beyond what is

viable for the farmer and agricultural applications. After studying the ingredients and coming to a conclusion that there could be some difficulty, due to a cartel of sorts on some of the ingredients, I declined the request but gave him a sample of a product that is supplied and used in the Sports & Amenity Turfgrass markets since 2007.

Having not expecting to hear anything I was somewhat surprised when I was called and asked for a meeting, in which I was informed that the tramline trials, where the product has been applied on various crops has resulted in very significant yields as well as noticeable plant health. That product has now been branded Exalt and instigated the formation of Bio Farming Ltd. Bio Farming Ltd was formed in 2018 that combines the knowledge and experiences of myself, Mark Atkins and Jeremy Hitcham.

Jeremy Hitcham, “I have been in the fertiliser industry all my life. Originally with Bunn Fertiliser for 19 years before the company was sold to Koch Industries, where I stayed on for 6 years eventually leaving to establish my consultancy, Fertiliser Limited. Shortly after I helped with ex colleagues from Bunn to established Payne Crop Nutrition at Fakenham in East Anglia. Later that year Mark and I had the opportunity to create BioFarming Ltd. A concept we had over many years hoped to create into a reality. We believe that many soils have been unknowingly neglected and by utilising a wealth of experience and combinations of our unique products we can make soils perform better”

Mark Atkins, “as a farmer’s son and having spent many long hours working the land and all that comes with the industry, I like to feel that agriculture is in my blood and my feet are in the ground, it certainly feels that way.” My career moved from farming to a spray operator and as an Arable Specialist with Dalgety Agriculture in the south of the country before a shift in to turfgrass production and management, which found me heading to Saudi Arabia for a 3 year stint managing the construction and maintenance of 12 new, one million USD pitches throughout the kingdom, followed by managing a 110 ha turf farm and the first all grass golf course perched in between the wadis and sand dunes 40 miles outside Riyadh with summer temperatures of 45oC plus and winters of -1.

A contract to supply 500,000 m2 (5 hectares) to Dubai, UAE, which was harvested as 20 m2 large rolls and washed with a homemade ‘turf washer’ resulted in the offer to manage the ‘grow-in’ and construction of the Abu Dhabi championship golf course, along with lots of other ‘must do’ items, involved the making a makeshift sprayer from a hydro-seeder tank and pump, a length of scaffolding pipe and irrigation sprinklers to apply some very noxious pesticides and homemade liquid fertilisers! A final move to Dubai in which I introduced an organic granular fertiliser for use on golf & other sports turf facilities before returning to the UK with my family in 2000. A fantastic experience with at times some very difficult growing conditions of brackish saline / sodic soils and questionable recycled irrigation water qualities, extreme temperatures and not to mention all those people I met along the way at work, playing rugby and parties.

Upon my return to the UK I was asked to and undertook the agronomy at various golf course construction projects, which were once again overseas where on making recommendation I was asked if I could supply the ‘specific grades / analysis’ of products as were identified and the fact that none were found in the catalogues of the supply trade companies. One Saturday afternoon at home and alone in the kitchen I blended various powdered mineral fertilisers with zeolites and humic acid. After knocking them about in a drum with some water, screening and then drying the granules in the oven, yes! all windows were wide open, I had produced a granular fertiliser. The then ‘Scotts Company’ based at Howden produced these specific grades on my behalf which were then sold to clients. This was the start of my formulating and trading of bespoke products After many hours of research reading and discussion with others, the vital roles from the myriad of the microbial communities in soils, plants, humans and every living entity was becoming more and more apparent.

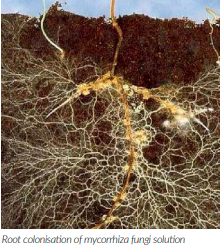

With colleagues, a combination of what I call ‘microbial nutriments’ were explored. Initial the product was of individual substances that were tank mixed before application whereas now a days many have been formulation as complexed solutions. The benefits of these was being seen by turfgrass managers on all sports turf surfaces with increased vigour and plant health. In 2007, a Dutch owned UK subsidiary bought my small company as the benefits from their aeration equipment coupled with applications of the ‘microbial nutriments’ were seen as perfect synergy. Research was undertaken at the Royal Holloway College (London University) with a PhD sponsored study on the effects of reducing soil compaction that resulted in the booklet ‘Life Beneath Your Feet’ c/o Charterhouse Turf Machinery Ltd Under the watchful eye of Professor Alan Gange further evaluation was undertaken to quantify the effects of the microbial nutriment on grass plants in as gown on a golf tee.

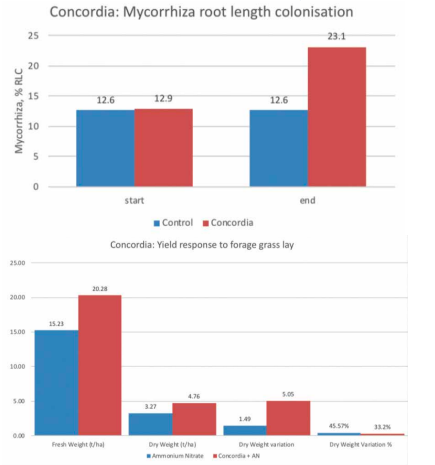

After what seemed ages of a 6 month period results were issued to great excitement as the applications had increased the root length colonisation (RLC) of ‘mycorrhiza’ from 12.6% to 23.1%. and beneficial bacterial abundance of 71%.

In the words of Professor Gange:- “In mycorrhizal terms, this is a large increase. We would not expect levels to increase to, say, 50% or 60% (i.e. those found in natural grassland) because of the carbon limitation imposed by clipping. Plants fix carbon through the process of photosynthesis and about 20% of the annual fixed C is directed to the roots to feed the mycorrhiza. This is the sole energy source for the fungus. Continuous leaf removal reduces the amount of C fixed and hence limits fungal abundance. Therefore, this product significantly increased the abundance of microbes, both bacterial and fungal, in the soil”.

This product now branded as Concordia has shown that the affect form applications on forage grass product has the ability to increase fresh weight yield by 5.05 tonnes / ha an increase of 33.2% and its dry mater content by 1.49 t/ha or a 45.6% increase. There is now becoming more and more data of the benefits of mycorrhiza for soil and plant health, the sequestration of Carbon Dioxide, efficacies of Nitrogen assimilation and others with subsequent and ongoing benefits. Since then various other substances have been appraised which continue to be applied to some very prestigious sports pitches and other sports turf surfaces (The Emirate Stadium Pitch, Liverpool Anfield Road, Leicester City King Powder Stadium Pitch, Cardiff City Stadium pitch and others).

Plant health and disease In sports turf the number of plant protection products are becoming less available as well as being very costly, where a single application of a fungicide can be between £600 – £1000.00 / hectare ??

With the use of the microbial nutriments, plant health elicitors in combination with precise nutrient applications plant health is improved and the incidence of disease infestation has become almost nonexistent. This means the grass plant, that is constantly under stress from daily mowing, the need to perform, possess high aesthetics and ‘for the game is not compromised from the negatives of disease infection and slow recuperation. The benefits to the clubs are financial, agronomic and environmental as the products are on the whole non-hazardous, being derived from sustainable plant extracts, bespoke and with most being produced in the United Kingdom flexibility, availability and delivery schedules are maintained.

The product range is not large consisting of four categories:

1 Microbial Nutriments and ‘Fertiliser Supplements’

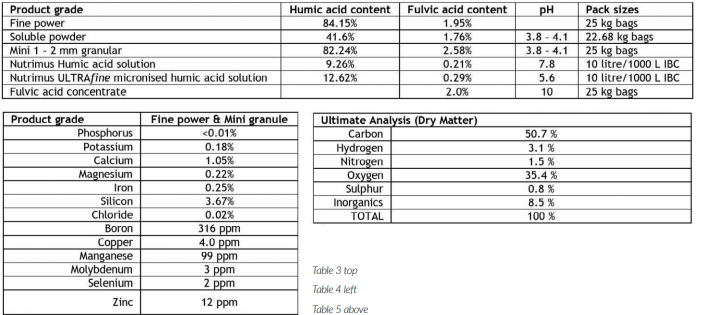

Humic substances, as powder, soluble powder, slow release granular, Liquid Nutrimus and Nutrimus UltraFINE grades These materials are available for direct applications or as supplements to granular and liquid ‘fertilisers’. High values of labile Carbon support microbial communities and help balance Carbon:Nitrogen ratios.

Composition:

Note Table 5 – * Leonardite ranges considerably in humic and fulvic acid content. For example, deposits can have as low as 10% humic acid content and as high as 78%. It’s derived from Lignite based coal and was formed in saltwater deposits. The other 20- 90% of the product that isn’t the active ingredient is made up of ash and heavy metals. The comparison of the two is clearer when you take into consideration the enhanced nutrient quality and properties Nutrimus has over Leonardite shale. Humic substances have been proven to improve the quality of soil, growth of soil organisms, and uptakes of nutrients by plants. The benefits of humic and fulvic substances are well documented.

The direct and compounding benefits where one benefit will lead to the next are:

• mprovement of soil chemistry and structure

• improvement of biological status of soils

• improved utilisation of nutrients supplied and obvious cost savings

• improved water utilisation and possible cost savings

• improved yield – higher income/ha

• improved quality – higher income/ ha

2. Plant and Soil elicitors & enhancers

Exalt

• A complex of 4 Non Hazardous botanical extracts with multifaceted modes of action within the soil, the plant rhizosphere and the growing plant.

• Organic surfactants help to diffuse liquid homogenously into the soil profile

• Microbial nutriments promote a rich biological ‘microbiome’

• Elicitors, promote Systemic Acquired and Induce Resistance, acting similarly as an inoculation, kick starting the plants own immune system

• Naturally occurring synergistic back ground nutrients & amino acids provide nutrition

• Apply Exalt at:

– pre sowing – post germination p

– Exalt can be tank mixed with most liquid nutrients and other compatible products

– Tank mixing with glyphosate and selected herbicides

– Tank mixing with selected fungicides

N.B. That all and every tank mix product should be first tested with a ‘jar tests’ as some adjuvants can be reactive. Exalt contains naturally occurring surfactants and tackifiers.

Application rates: o Cereals & OSR 1.5 – 2 litres / Ha o Root crop (carrots, potato) 2 l/ha o Legumes 1 l/ha

Protos

A liquid EC FERTILISER – PK Fertiliser solution: containing

• Potassium Phosphite 50% Liquid contains a high level of Phosphate at 30% w/w in Phosphite form.

• A very good P-source that also increases general plant vitality and resistance to stress.

• Developed to fertigate in soil grown covered crops and hydroponics as well as for foliar application. Also suitable for dipping plant roots prior to transplanting.

• Transparent liquid solution of high purity

• Improves general plant immune system

• Enhances root growth

Product Characteristics

• Production process certified according to ISO 9001:2015

• Highly concentrated solution

• Low on Sodium and Chloride

• Low on heavy metals

Apply at the higher application rate during period of high stress. Tank mix with fungicides to increase efficacies. Apply at 5 – 10 l/Ha

Micronised Mineral Nutrition

• The Parvus product range of micronised mineral nutrients are available as liquids and wettable powders are used extensively for sports turf management, which are now being used in agriculture.

• By micronising mineral elements their ability to be accessed by microbes and assimilated by the growing plant is very evident with plant response to health and subsequent yield increases, higher dry matter content all of which lead to reduced risk of infection, better shelf life and nutrient contents.

• It is not uncommon to attain dry matter contents of perennial ryegrass of >30% with metabolisable energy values (M.E) of 12 – 13 kJ/Kg.

Research and Development

R&D is and will be an ever ongoing process in order to better understand these and now materials to determine application rates, timings & frequencies and also most importantly when not to apply. The evolution of Bio Farming is in real terms just beginning with comprehensive trials to be undertaken this year and as on going to quantify the carryover of benefits for subsequent crops and soil health

Soil Health – the new Muck and Magic’

I know that is this publication the awareness of all matter biological, microbial is well appreciated, yet there is still the belief that all these types of products are ‘muck and magic’ well, that is exactly what it is mother nature working her magic as has always been so.

Cause and Effect

Certainly, in sports turf, the client with whom I work, will ask the question ‘what is the cause of a particular issue and plant condition’ as opposed to reaching for the pesticide bottle.