DRILL FOR THE MODERN ERA

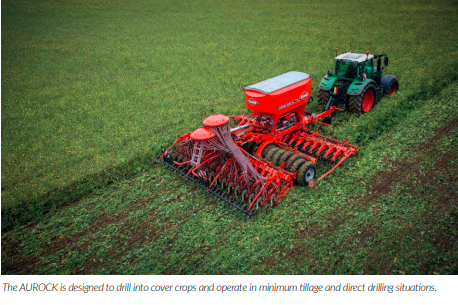

A seed drill that meets the needs of today’s progressive arable farmers needs to be strong, precise and, perhaps most important of all, versatile. That’s the mindset that’s been adopted by KUHN in the development of the AUROCK, which was launched at SIMA 2019 this year. Combining proven drill technologies that have served the company well for over 40 years with real innovation, the Aurock is a machine to operate effectively in the conservation agriculture environment and beyond. As KUHN UK product specialist Alex Birchall explains, conservation agriculture requires a rethink in the approach to cropping. In the same way, drill manufacturers need to tackle machine design and configuration from a fresh perspective.

“Where ploughing is replaced by varying degrees of shallow tillage, or if establishment is to be achieved into an existing crop, the role of the drill becomes more crucial than ever to the success of the system,” he says. “KUHN has longstanding experience in drill manufacturing, including direct drills, so the development of a machine that provides solutions in the broad range of conditions seen in minimum or zero tillage situations has been a natural progression.” The AUROCK is available in a sixmetre format from the summer of 2019, with single and dual metering units. The single metering unit version (AUROCK R) has a 3,500 litre capacity hopper and the double metering unit version (AUROCK RC) has a 5,000-litre capacity split hopper. It is designed for a low horsepower requirement, needing a modest 180hp to operate.

The drill’s ability to work in varying field conditions starts at the front with two rows of opening discs. There is the option of 460mm diameter corrugated discs, for working in prepared soil of soil mixing, or a 430mm diameter embossed disc for cutting residues efficiently and minimising soil ejection. Seed placement is carried out by the double-disc seeding unit mounted on a parallelogram for optimum delivery accuracy and perfect ground following. Alignment with the opening discs is maintained by a central pivot point between the coulter bar and the chassis. This ensures that seeds drop accurately into the furrow, whether the drill is operating on a slope or around a bend. The opener discs and seeding unit assembly form the triple disc that has underpinned KUHN’s success in drill manufacture for forty years.

Dual metering

Choosing the AUROCK 6000 RC dual metering option adds numerous possibilities, including dual cropping or alternate row drilling with independent management of seeding depth. These options are increasingly relevant for farmers seeking more innovative cropping solutions, whether for pest control or improving soil health. The modular design of the AUROCK allows the option of an integrated cutter roller with adjustable pressure to enable efficient operation in all cover types. The transport wheels are positioned between the opening disc and the coulter bar. The machine can also be equipped with a whole-width wheel train for seeding

within a minimum tillage cropping system. The offset press wheels prevent soil from building up at the front and amplify the versatility beyond direct seeding. They allow the passage of plant residues and reduce pull power requirement. Their large diameter of 900mm reduces rolling resistance. The AUROCK seed drill is an ISOBUS compatible machine, available with CCI 1200 or CCI 50 terminals (ISOBUS certified by the AEF). For comfort, a joystick is also available as optional equipment. Regardless of the selected control terminal, the operator has a user-friendly and intuitive interface developed specially by KUHN. A simple press of a button at the headland allows successive lifting of the front tools, then the stop of the metering unit(s), ensuring perfect seeding to the edge of the field. This ensures no seed remains on the surface, overcoming a common problem of direct seeding.