The journey of an agricultural dealership to be able to offer customers more…

At the Farm Expo Show at the Kent County Showground, we got a chance to hear from the team at Burden Brothers about the field trials they have started. George Whelan and Kris Romney were on stage talking to the farmers who attended the seminar

As a dealer they are looking to do more than just sell you machinery. They want to understand better the journey a farmer takes when looking at alternative solutions on their farm. They want to understand better how the choices farmers have in terms of the machinery they use effect the value they represent to their business. They want to work with the customer to make sure they have a good return on investment. This is a new approach from a dealer and represents their willingness to become better at advising on farm and not just be a place to sell you machinery.

To learn about the process, they decided to set up an on-farm trial. To grow a crop under several different establishment methods and take it to yield. For not just one year, hopefully for many years to come. Using all the tools at their disposal to measure and observe how the soil changes (and the changes required to the soil) over time. The key aim of the trial is to understand establishment methods and the different agronomic challenges they require and to see how they allow a farmer to tackle the issue of blackgrass on their farms.

In many ways this mirrors the journey many farmers themselves are on. Having read a guide, like the one in the last issue of Direct Driller Magazine from ADAS and learning themselves from their own farm trials. However, in this instance, the farmer has the help and support of a dealer. Sounds like the support we would all like to have!

The Trial

The starting point of the trial is drilling directly into pea stubble with a first wheat. Using a 750A, no-till drill, a Sumo DTS both compared to a Vaderstad Rapid pulled by a tracked Challenger (this forming the control and the existing form of establishment currently used on the farm.

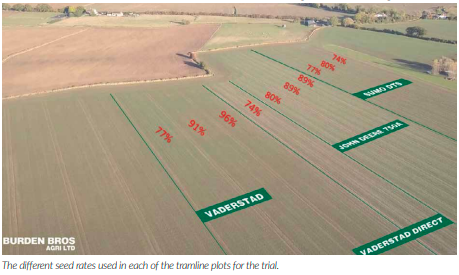

They are using a 33 hectares field, very flat field from a local famer Andrew Martin of Broadstream Farming. Down in Romney Marsh. This is an area affect by blackgrass and they are very interested in looking at different methods of blackgrass control and specifically how three different establishment techniques affect blackgrass populations. The multiple tramline plots can be seen in the picture above

As can be seen, part of the plot was cultivated and that was drilled using the Vaderstad as they would normally on the farm. The other section wasn’t cultivated and was drilled direct using the Vaderstad Rapid, the John Deere 750A and the Sumo DTS. The trial is also using different seed rates within each of the tramlines. 350,400 and 450 seeds per square metre. 350 was as close to the farm standard as possible and equated to around 175kg per hectare.

Year 1 will be wheat, Year 2 will be second wheat, Year 3 will be decided at a later date. Being a multiple year trial in such a big field this also gives Burden Brothers the options to look at agronomic changes as well.

The Initial Results

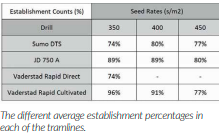

Already they have carried out establishment counts for emergence in December 2018. 6 measurements using quarter meter square counts. But because of the wider row spacing of the coulters on the DTS, this 25cm x 25cm test might not give representative results at this stage. More will be learned by further counts in the spring.

It is noticeable that the highest seed rates didn’t give best establishment, possibly due to increased competition. The results are similar (probably within a standard deviation) and therefore we will learn more as further counts are taken in the spring and then ultimately what yield each tramline produces.

At What Cost?

The next step to consider is the cost of establishment. The average establishment percentages are: 88% for the Vaderstad cultivated plots, 86% John Deere 750A plots and 77% for the Sumo DTS plots. This is where you start looking at the cost of establishing each plot. The requirements can be seen in picture 3 for each of the plots. The £58 cultivation cost per hectare only applies to the Vaderstad plot and is based on standard contractor rates. The first question is therefore, whether the increased establishment % of the Vaderstad will produce additional value over the additional cost of establishment. Something that will be able to be quantified come harvest.

They will also need to factor in the costs of the machinery required to complete the establishment (averaged over the size of a normal farm) to give a more accurate result. The AHDB have run a few webinars recently and one was on costs of establishment. It was very interesting and worth watching if you missed it. It will help you realise where your costs sit now compared to one of their monitor farms for which they have excellent sets of data. If you want to see a short video that Burden brothers have made that brings the trial more to life than just words can, you can see it by pointing the camera on your phone at the QR Code below:

What Next?

In the spring, they will move onto tiller counts, this may show better where the DTS crops have the space to grow and thrive. It will also allow Burden’s to see how these different methods effect weed control? This will be a big part of later events they hold on the farm, that you can sign up to directly with them.

Data Quality

The big part of doing any trial is having the data to back up any results. A single result doesn’t really tell you anything without lots of data points to back it up. The yield map from the last wheat crop in this field will give the starting point. The John Deere combine they will be using at harvest has yield monitoring so they will be able to create yield maps postharvest to add further statistics. The data that is backing up the trial will allow the results to be checked to see if they are statistically significant for that field. Burdens also plan to take samples from each section to determine quality of the wheat grown to quantify and difference across the plots. Next date on site is 26th June, there will be another field walk. They will have tiller and blackgrass count by then and everything will all be brought back to cost of establishment. They are very interested in not chasing the biggest yields but looking for the most profitable way of farming.

Agronomy

In year 1, the agronomy will be the same across the whole field. There are certainly options in a field this size to also look at other changes, such as using cover crops between cash crops which we often hear is an essential part of consistent and sustainable direct drilling systems. Tweaks to the timing of nitrogen applications (not changes in rates) for the direct drilled plots would also help Burden Brothers expand their knowledge around different systems and the agronomic requirements they have.

Conclusion

It is interesting that dealers are now taking the same journey to learn as farmers, doing their own trials. Working with farmers more to be able to offer better advice prior to customers looking to change systems. It’s a perfect combination for a lot of farmers, to have the ability to assess machinery before they make any decisions. To be able to make those decisions with a dealer who has spent time to learn and invest in their staff’s knowledge. This is a trial we will follow with interest to see how they get on and how it changes the way they interact with their customers.