NEWS FROM SLY – written by George Sly.

Sly are excited to announce that we are now UK and France Premier dealers for Precision Planting Inc, a subsidiary of Agco Corp. This opens new horizons for us in terms of technology and the ability to offer customers machines and components to significantly enhance the way they farm. The main reasons we decided to take on the dealership was through testing on our own farms of PP technology. It really unlocks many of the barriers we face in conservation agriculture. Precision Planting offer both OEM control system solutions as well as retro fit components to enhance your existing drill or planter. They have a vast engineering team based in Tremont, Illinois. The company was started by a farmer with simple retro fit components to enhance planter/drill performance, he then sold the company to Monsanto, later Monsanto sold it to Agco.

Some examples of technology we are now fitting to our own precision planters, as well as offering as retro upgrades to existing machines:

Smartfirmers:

Smartfirmers are in furrow sensors we can install on existing planters or drills. These sensors are live monitoring:

Organic Matter

CEC

Moisture

Temperature

Residue levels at drill depth

All of this information is live fed to the Precision planting 2020 monitor which stores and uploads maps to the cloud. You might ask why do we need all this information? Firstly when you take a move to conservation agriculture, certain aspects like Cover cropping, composting, no-till etc are moving you in a direction you hope is improving your soil. With this sensory technology every time you drill/ plant, you get a reading, so you can track your progress in your transition. Secondly, this technology on our machines can live adjust seed rates and fertiliser rates based on what it is seeing in the field. It can also switch seed variety/hybrid based on what it is seeing in the seed furrow. If a different variety maybe better suited to certain areas of the field the control system can switch to take seed from a separate tank. It can also control seeding depth based on moisture levels it is seeing.

Deltaforce:

I tried Deltaforce for the first time in Spring 2018 on our prototype maize planter. Deltaforce is a downforce system we can install that monitors and adjusts down pressure and load on the planter/ drill gauge/closing wheel, each row individually. It adjusts the pressure to each row unit/opener 5X per second. When planting sugar beet last spring, my field contained light silt hills and heavy clay lows, we could maintain a plant speed of 10km/h and keep depth +/- 1mm consistent. The 2020 monitor displays the KG it is placing on each row, sometimes it is negative in light soils and then positive load in heavy areas. My soil is marginal to grow precision row crops, but Deltaforce insures I can achieve even depth placement in a no-till/strip-till situation. All major European precision planters are designed for a full or mintill systems where the seedbed is very consistent and level. I am using no-till and strip till, my seedbed is not quite as even or consistent and so Deltaforce is the “key” to having uniform emergence and success.

VapplyHD:

VApplyHD is a liquid fertiliser control system using PWM technology. We monitor and control the flow on a row by row basis, we record exactly what we have delivered to each row and it is recorded on maps (which can then be compared to yield maps). The system can be spec’d as advanced or simple as the customer requires, but it is a huge leap forward in the accuracy of liquid placement for all drills and planters.

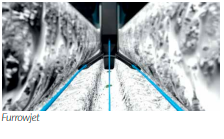

Furrowjet + Conceal – THE KEY TO RELIABLE MAIZE ESTABLISHMENT IN THE UK?

Furrowjet is a fertiliser attachment for planters, it allows us to place 3 bands of liquid, the first one is in the seeding line, the other 2 are ¾” either side of the seed furrow. For Maize this means we can place all the P+K plus some of the N requirement very close to the seed. Maize is a C4 tropical plant, we are growing it in a high latitude and to maintain and achieve reliable yield we have to get it from emergence to V5 growth stage very quickly. ALL the yield potential is set before V5 in Maize. All conventional granular planters available in the UK are generally using granular DAP in a 2”X2” system. For one, granular DAP is not as available to the plant, especially when we talk of Phosphorous, secondly, being 2X2 on one side of the seed trench it is slower to be accessed. That is time we cannot afford with our short growing season.

Conceal is a new system that we can retro fit to almost any maize planters on the market, of course it can also be specified on our planters. Conceal replaces your existing maize gauge wheel and it incorporates a liquid application knife 3” to the side of the seed trench, meaning you can place your complete N requirement for the maize plant at planting time, it is far enough from the plant not to cause any burning issues. Conceal can be fitted on one or both sides of the planter row unit.

Sly is looking forward to introducing these products to the UK, through our farm open days and farm walks the results can be seen. We welcome farmers to visit our farm and company to learn more about our products and the systems we are trying. We have 3 maize/Beet/ OSR planters being delivered this spring and plan to expand our presence in this market for the 2020 season.

Maize planters are currently available from 4 to 18 rows, in 2020 we plan to introduce central fill options for larger high output planters.

New from our Farm:

Covers drilled in November? Can it work?

One field we harvested forage maize from was supposed to come Winter Wheat, too much blackgrass was present so I decided to put it to maize again. It was early November and so drilling a cover crop would seem a waste of money and time. However I have been pleasantly surprised using Forage Turnip rape and Italian ryegrass we have had really good over winter growth and will have another 4 weeks growth until maize planting. It just shows in the right season you can still grab carbon and store nutrients with late drilled covers, something for Veg and Potato farmers to consider. It wont work every year for sure.

Boss drilled winter wheat after Maize

We drilled our winter wheat in late October following maize with our Sly Boss 6M drill. We also applied molasses and bacillus microbes in the furrow as a trial on around 70 hectares of Zyatt wheat. We are monitoring the difference to a untreated area. I am not expecting big visible results in one year, but we are trying to treat fields with microbes, sugars and fulvic acid over a 3-4 year period with the drill and planter (not surface applied) to monitor any changes.

Trials coming up:

We are taking 2 hectares out of production to trial vegetables and salads using strip till with interrow covers/ mulches. Much of the focus on no-till is on cereal production and we want to try and improve the efficiency of vegetable and salad production. This is after all what most of us eat every day. We will update any progress in future Direct driller issues.