VIRKAR – IMPORTED BY SAMAGRI LTD

Successful Spring Testing

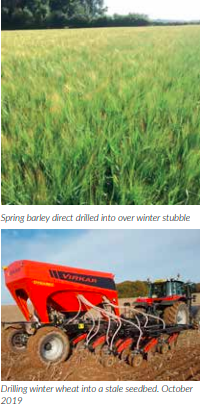

This article follows on from successful spring testing of the Virkar drill on our own farms, where we drilled a range of crops from spring oats, spring barley, maize, and sunflowers for environmental schemes. The results were very pleasing with great crop emergence due to the very precise seed depth placement, which comes from the drills unique ground contour following capabilities. We also found that the way the coulter design works with the front turbo disc working 2 cm deeper than where the seed is being placed, the plants root system benefitted greatly from having tilled soil underneath the seed, meaning the roots of the plant were able to go straight down meaning a stronger healthier plant. We were very encouraged by the early signs of the drills performance and how easy it was to use in the field. And following on from a successful launch at the Groundswell show we had plenty of interest in the drill and had demos scheduled for the Autumn.

Looking ahead

We knew heading into the autumn this would be the chance to really test the drill in the conditions it was designed for: direct drilling into hard ground with a lot of crop residue. Due to the high yields of the crops this year meant there was a lot of crop residue to deal with. Combine this with hard dry ground and we knew the drill would be tested.

Early Autumn Drilling

We started off by drilling cover crops into chopped winter wheat stubble, there was a lot of crop residue to deal with and with the ground being dry and hard this was a good first test. The drill coped well with the crop residue and managed to establish the cover crop no problem. However, we did find that the two rubber closing wheels in places were not closing the slot entirely due to the hard dry ground conditions. This problem was soon solved, as the drill came equipped with two different closing wheels the rubber wheels and steel wheels which are narrower and harder. To change the press wheels, it is just a case of undoing one bolt on each wheel and swapping between the two wheels. After the steel wheels were fitted, we took it to the field and immediately saw the difference. The slot was being closed much easier without the need to have too much coulter pressure applied.

New Aggressive Opening Disc

We then went to drill in some chopped spring barley stubble, we found with the increase in crop residue the standard front cutting disc, on the drill in places was struggling to cut through the residue before the seeding boot meaning we had a bit of residue build up round the seeding boot. The factory however had already been testing a different cutting disc to deal with increased amounts of crop residue. We had a set for the drill already in stock, so we put 5 of them on the drill to compare between the two. The results were very encouraging the new disc with its more aggressive cutting profile dealt with the crop residue much better, so it was agreed that in situations with lots of crop residue these discs would be the preferred option.

Late Autumn Drilling

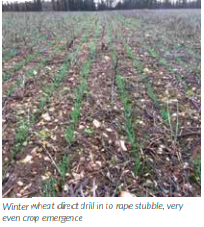

The last six weeks have been challenging but in a very different way. We always knew the drill would work in the wet from seeing the machine out in Spain. The first test came drilling winter wheat straight into rape stubble. This was in some heavy clay at one end of the field to light chalk at the other the benefit of being able to adjust coulter pressure on the move enables us to apply just enough coulter pressure to close the slot without smearing the slot and capping it over.

We also found that because of the light weight of the drill it was able to carry on drilling in the wetter conditions when other drills were parked up. Regardless of the conditions we were drilling into, which at times were far from ideal, the seed was always placed into a good tilth and the drill managed to keep going. Even in these testing conditions the drill was being pulled with 200hp which handled the drill no problem at all. Fuel usage of 4lts/ha was very pleasing too. We were hoping to drill some winter beans and test the new bean coulter, but due to having 350mm of rain in the last 8 weeks this has not been possible.

Summary

Since the drill arrived in the UK, we knew that we wanted to test it to the extremes and iron out any issues or changes needed. The drill has coped with everything we have thrown at it and every crop we have planted has established well. We also tested the drill locally on other farms with pleasing results. Now that we know the drill works for us on our own farms the drill is now ready to be marketed across the UK and hopefully with the attention the drill has gained already, It will become a real contender in the competitive emerging market of no till drills.

We will have a new 6m Virkar Dynamic drill with split hopper on our stand 20.708 at LAMMA 2020, so we hope to see you there.