CHALLENGING AUTUMN UNDERLINES THE NEED FOR A CROP ESTABLISHMENT SYSTEM TO COPE WITH ANY CONDITIONS

The extreme wet weather this autumn underlined the importance of operating a system which can cope with all conditions, of soils being in optimum condition, minimising weather risk and having sufficient capacity to take advantage of weather windows, says direct strip seeding pioneer Jeff Claydon, who designed the Claydon Opti-Till® System.

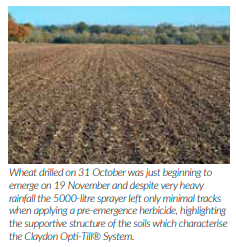

In the last issue of Direct Driller magazine, I talked about the importance of ‘cost per tonne of production’ as a key metric of efficiency for arable farms. This time, I will discuss crop establishment on the Claydon farm this autumn. Undoubtedly, it has been the most challenging since 2012 in terms of rainfall, but even though our Hanslope Series clay is one of the heaviest soil types in the UK we managed to drill all our winter wheat by 31 October. As I write this on 19 November the average of soil temperature readings at depths of 300mm and 600mm is 6.8°C, which is 25% lower than a week ago, but my brother, Frank, has just drilled the last of the winter beans to complete our planned autumn crop establishment programme.

I am fully aware that many farms in the UK have been unable to get any crops in the ground this autumn and sympathise with them. Others have only been able to establish perhaps 50 per cent of their planned area and even some of those crops might not amount to much, while others will have to be re-drilled in the spring because seed has rotted in waterlogged soils. Many of our counterparts in Northern Europe, including France and Germany, are experiencing similar conditions, so it will be interesting to see by how much production declines and what impact that has on grain prices.

Keeping It Simple

The key to establishing crops successfully under all conditions is to operate a simple system which minimises weather risk, has a high output so that you can press on when Mother Nature allows and generates progressive improvements in soil condition, structure and health. On the Claydon farm in Suffolk the predominant soil type is Hanslope Series clay, one of the heaviest in the country, which must be worked when conditions are right. It has benefited significantly from 17 years’ use of the Claydon Opti-Till® System, which produces soils that drain more freely in wet weather yet better retain moisture when it is dry, the high output allowing us to wait for favourable conditions, then establish crops quickly and efficiently.

In a wet year such as this the patented design of the leading tine used on all Claydon Hybrid drills is invaluable, although this autumn we operated at a slightly higher forward speed, 12km/h rather than the usual 10 km/h, to increase soil shatter. The fact that the leading tine cultivates zonally, alleviates local compaction, aerates the soil and improves drainage, allowed us, and other Claydon users, to operate over a much wider weather window than disc-type drills, which generally will have not performed well this season. Additionally, because the Claydon drill’s lugged support wheels run only on uncultivated ground it has been able to operate without restriction when others would simply have clogged up with sticky soil and been side-lined.

One change that we did make this year was to use 12.5cm-wide (5”) A-shares on our 6m Claydon Hybrid T6c in place of the standard 17.5cm (7”) versions. The idea was two-fold, firstly to concentrate the seed in a tighter band to help crowd out weeds within the crop row and secondly to provide slightly more space between the 300mm rows, leaving more bare soil so that any weeds not taken out by herbicides could be removed easily and effectively in the spring with the Claydon TerraBlade inter-row hoe. This area will be one of the attractions for visitors at the Claydon Open Days in May.

Oilseed rape was the only crop established in good conditions. We drilled 70 hectares on 9 / 10 August and 15mm of rain fell immediately afterwards, ironically providing much-needed moisture to start the germination process. The crop got away well, weathered pressures from Cabbage Stem Flea Beetle successfully and in mid-November was in great shape. The next challenge will come in the spring from CSFB larvae, but the crop is well advanced.

Soils Are In Great Shape

It seems hard to believe now, but when we started our stubble management operations after harvest the soil was so dry that volunteers and weed seeds would not germinate, meaning that we had to exercise patience and hold back. We started again in September after rain fell and subsequently took out multiple flushes of weeds. We used our 6m Claydon TerraStar light rotary cultivator and 15m Claydon Straw Harrow to create 3cm of highhumidity tilth which encouraged volunteers and grassweeds to germinate. These were sprayed off with full-rate glyphosate prior to drilling and the high level of control achieved will take the pressure off residual herbicides.

When the weather turned wet at the end of September it brought an end to our stubble management activities and in the following weeks the rain was relentless, so thank goodness for glyphosate. Fortunately, after 17 years of using the Claydon Opti-Till System our soils are in excellent condition and the deep fissuring created by two years of dry weather further helped to transport water away from the soil surface.

The saviours this autumn were that soil temperatures held up and we didn’t need to prepare seedbeds in advance of drilling, so could go straight into stubbles with the TerraStar followed soon after by the Hybrid T6c. In some areas the soil was so nice that we might have even gone a little too deep and created too much tilth! It is important to remember that the top 2 to 3cm of tilth dries in half the time compared with the next 2 – 3 cm, so you must minimise weather risk by not over-working land ahead of the drill.

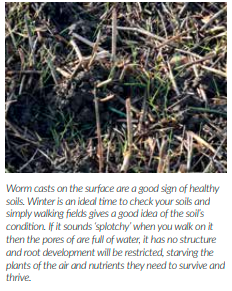

The wet conditions sent our worm population into overdrive and fortunately these little helpers have been very active. The casts which they leave on the surface are one of the best signs of healthy soils and the channels they create, some over two metres deep, have been invaluable in helping to drain water from the surface. Despite exceptional rainfall our soils retained an excellent crumb structure and crumble between the fingers rather than clumping into a sticky, anaerobic mess.

Our autumn drilling was completed a little later than planned and we drilled another 400 acres for other farms, but while all the contract oilseed rape area went in the additional wheat and beans area was limited by the exceptionally wet weather. It was certainly too wet to roll any autumn-sown crops but going over the beans with a Straw Harrow after a frost will break down any clods and level the surface to maximise the effectiveness of herbicides.

Because the leading tines of the Claydon Hybrid drill leave 40% to 60% of the soil area unmoved, the ground was sufficiently supportive to allow our 5000-litre self-propelled sprayer to operate when we wanted without damaging the soil, enabling Liberator and Movon® to be applied as planned.

Right Tools And Techniques Are Essential

Given the extremely wet weather this autumn it would have been unrealistic to simply muddle seed into poor, cold, wet seedbeds and expect good results. Patience is essential, as without the right conditions for it to germinate and grow away quickly there is a significant risk that seed will simply rot. Unfortunately, that is exactly what happened on many farms this season. Some soils that were ploughed after harvest may have dried out and, although may have drilled well, this would have come at a high cost in terms of wearing metal, fuel use and overall cost of establishment. On the other hand, many crops established after ploughing or min-till in wet conditions will have suffered from non-existent or poor development and will need to be re-drilled in the spring.

Similarly, where disc-type or no-till drills were used in difficult conditions the results are likely to have been poor because compaction will not have been alleviated, water will have been unable to drain away and seed will either have rotted in the rows or its development been stunted. Whether or not you believe in ‘climate change’ we do seem to be having more extremes of climate of late and the challenging start to this new season has highlighted the importance of using an establishment system which gives you the best possible chance of success, whatever the weather.

To learn more about the Claydon Opti-Till® System and techniques to improve your farm’s performance contact your local Claydon dealer and arrange a visit to the Claydon farm. For further details go to www. claydondrill.com or call the Claydon office on 01440 820327.